Blame the Torque Converter – Part 1

Society often influences us to try to blame others for our problems. From an early age we try to place blame with friends or siblings. Our training usually continues into our school age, when the guilty person is always “the other guy.” It seems only natural for this mindset to continue into the workplace. This is especially true if your workplace happens to be with the automatic-transmission industry. The mysterious inside of a sealed torque converter is easily substituted for the “big dumb kid” in the back of the classroom. The following are examples of a torque converter being unjustly blamed for a transmission problem.

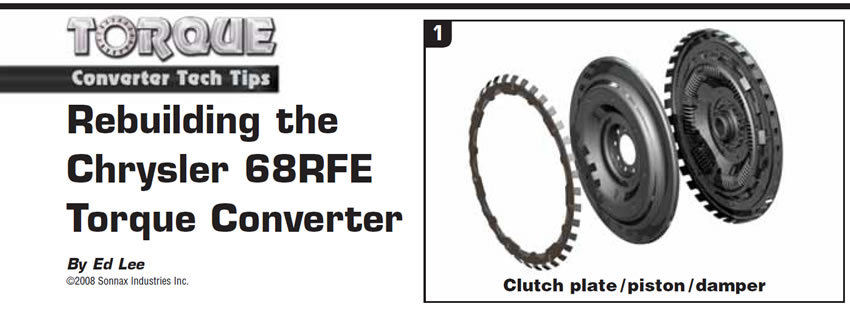

Rebuilding the Chrysler 68RFE Torque Converter

Along with this new transmission came a new torque converter, manufactured by ZF Sachs. The converter may look somewhat similar to its predecessor, but, as they say, looks can be deceiving. The stator in the 68RFE converter is the same type that was used in the 47-48 RE converters, but that is where the similarities end. The turbine looks as if it is the same as the earlier models, but appearance is all they have in common.

Solving the Mystery of Stator-Cap Wear

At this point most engineers were assuming that the stator-cap material needed to be upgraded, and that is where they focused their research. However, we all know what assuming does.

Fine-Tuning the Bonding Process

In a torque converter the friction material most often used on a lockup piston or cover is a mix of fibrous materials in a phenolic resin. The adhesive used to bond this material to steel is also phenolic based. Phenolic is a thermo-set type of plastic, and this plastic has unique properties.

Mystery Noise in the ZF 5HP19/24

It’s not uncommon to hear customer complaints about a noise coming from a vehicle equipped with either a ZF 5HP19 or ZF 5HP24 transmission. The noise is most often described as a squealing or squawking sound and can be heard when the customer lifts his foot off the accelerator pedal. The sound is similar to that of a bad transmission pump and can be heard in any forward range but is most noticeable in first or second gear.

Ins & Outs of Impeller Vanes and Weld Gaps

The movement of a vehicle relies on the torque converter’s ability to transfer the torque of the engine to the transmission (the beginning of the driveline).

More Details

Producing a quality rebuilt torque converter is a major accomplishment. You have to perform many rebuild procedures correctly to end up with a quality finished product. Simply knowing the difference between the right and wrong way of doing a rebuild procedure doesn’t always guarantee success. It’s important to pay attention to the many details of the rebuild, and the proper use of shims is one such detail.

It’s All in the Details

If you want to rebuild a torque converter and do a good job, you need to pay attention to many details. Unfortunately, in today’s business environment that critical attention to detail is often sacrificed in the race to just get the job done and get it done quickly. If you were fortunate enough to have a good mentor when you were learning about torque converters, you learned that there’s a right way and a wrong way to perform most tasks. In some cases there’s a right way and several wrong ways to do the same job.

Clutch-Release Clearance 101

In a torque converter, clutch-release clearance (CRC) is the distance that the torque-converter-clutch (TCC) piston travels from the release to the apply position. This distance is also the amount of free play that is available to the clutch or clutches when the TCC piston is in the release position.

Identifying Those GM 300mm Dampers

The 300mm converter has become very popular in GM units. First used in the Corvette and F-model vehicles (Firebirds and Camaros), today it is also used in most trucks, vans and SUVs. The converter is also manufactured in a 280mm version (VJCX, for example).

Which Generation of Torque Converter?

Since the release of the Allison 1000/2000/2400 series transmission, four basic torque-converter configurations have been used. TC-210, TC-211, TC-221 and TC-222 can be found in Group 21 of the Allison Parts Book, and these four converters all have different stall torque ratios and “K” factors. Over the years several revisions have been made to the torque-converter assembly process for all four converters, and each time a change was made, a new part number was assigned. None of these changes had an effect on the performance or functionality of the torque converter. Different generations of each of the four converters are completely interchangeable with other generations of the same type.

Torque-Converter Forensics

When a torque converter fails, the results are quite often catastrophic. It may be difficult to determine which component failed first and even more difficult to determine the root cause of the failure. Each failure should be viewed as an opportunity to learn, and a failure that is caught before the catastrophic stage should be viewed as a golden opportunity.