Issue Summary:

- In some instances, the Park/Neutral position switch on General Motors 4L60-E cannot be removed. Related problems may occur, such as the dash indicator showing either an improper shift or no shift, or no back-up-light operation.

- A speed-sensor-harness repair kit now is available for General Motors 4L80-E and 4L80-EHD. Part numbers are included.

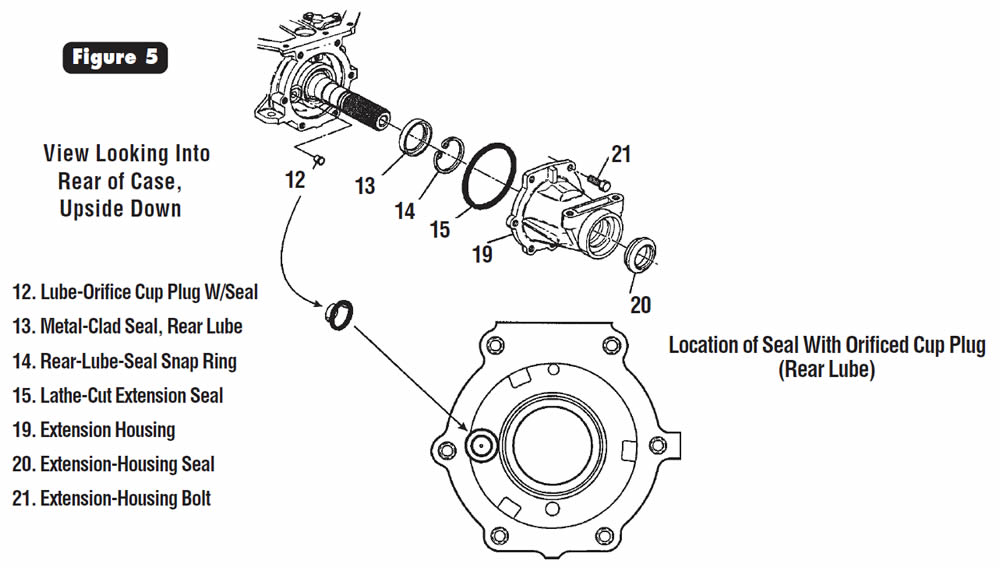

- The location of the rear lube seal and orifice on General Motors 4L80-E and 4L80-EHD is still a problem for many technicians. We have illustrated this location.

- Premature failure of the 3-4 clutch in General Motors 4L60 and 4L60-E units usually is associated with vehicles used for police, taxi or other heavy-duty service.

- No upshift from first gear after overhaul of a Chrysler A500SE (42RE) may be caused by excessive wear on the overdrive-piston support where the low-reverse drum rides.

- After rebuild, some Chrysler 42RE vehicles may have a 1-2 upshift shuttle that may lead to an incorrect diagnosis as a valve-body problem.

Technicians may experience difficulty in removing the connector from the Park/Neutral position switch on some 1995- to 1998-model trucks and vans during transmission service. In rare instances the customer may report switch-related electrical problems, such as the dash indicator showing either an improper shift or no shift, or no back-up-light operation.

The cause may be high ambient heat causing the sealing compound in the switch to melt and flow into the connectors, which will seal the connectors to the switch. This normally causes no customer concerns but in rare instances may cause an open electrical circuit.

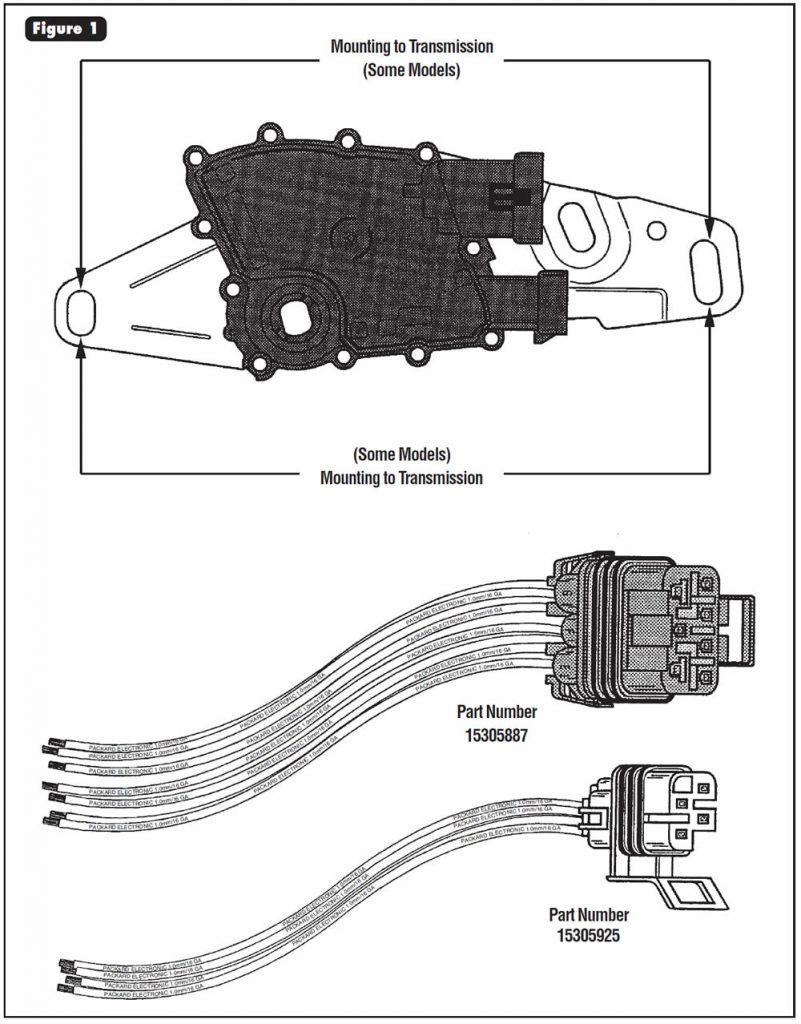

If the switch is being removed as part of transmission service, and there are no switch-related concerns, the switch can be removed without removing the connectors and left hanging until time to re-install the transmission. However, some models have a mounting bolt directly behind the switch connectors that requires removing the connectors. The switch will be damaged in the process (See Figure 1).

Now available from OEM sources are service-repair connectors for both the 7-way and the 4-way connectors under part numbers 15305887 and 15305925 (See Figure 1).

Note:

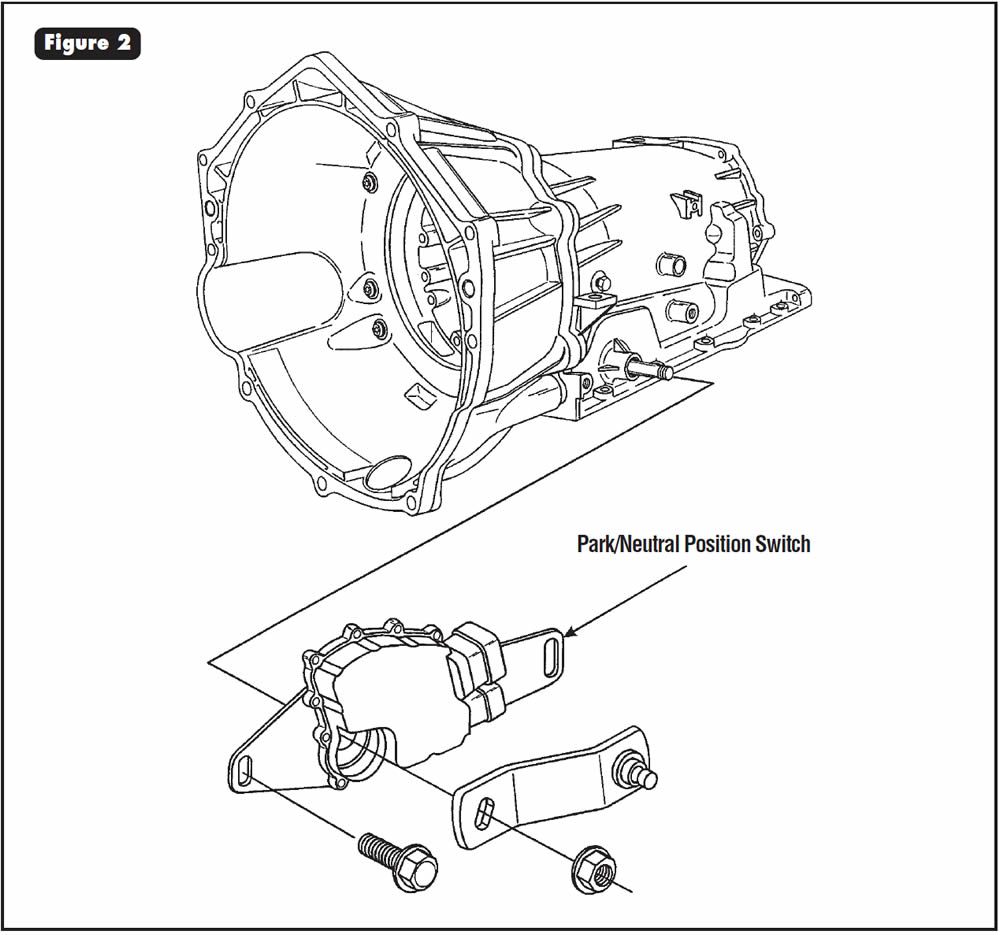

The service-connector pigtails use wires that are all the same color. Use the old connector as a pattern to ensure that the new wires are connected to the vehicle harness correctly. This switch is in a wet area, and it is imperative that you solder the wires and use heat-shrink tubing to ensure water-tight connections. See Figure 2 for the location of the Park/Neutral position switch.

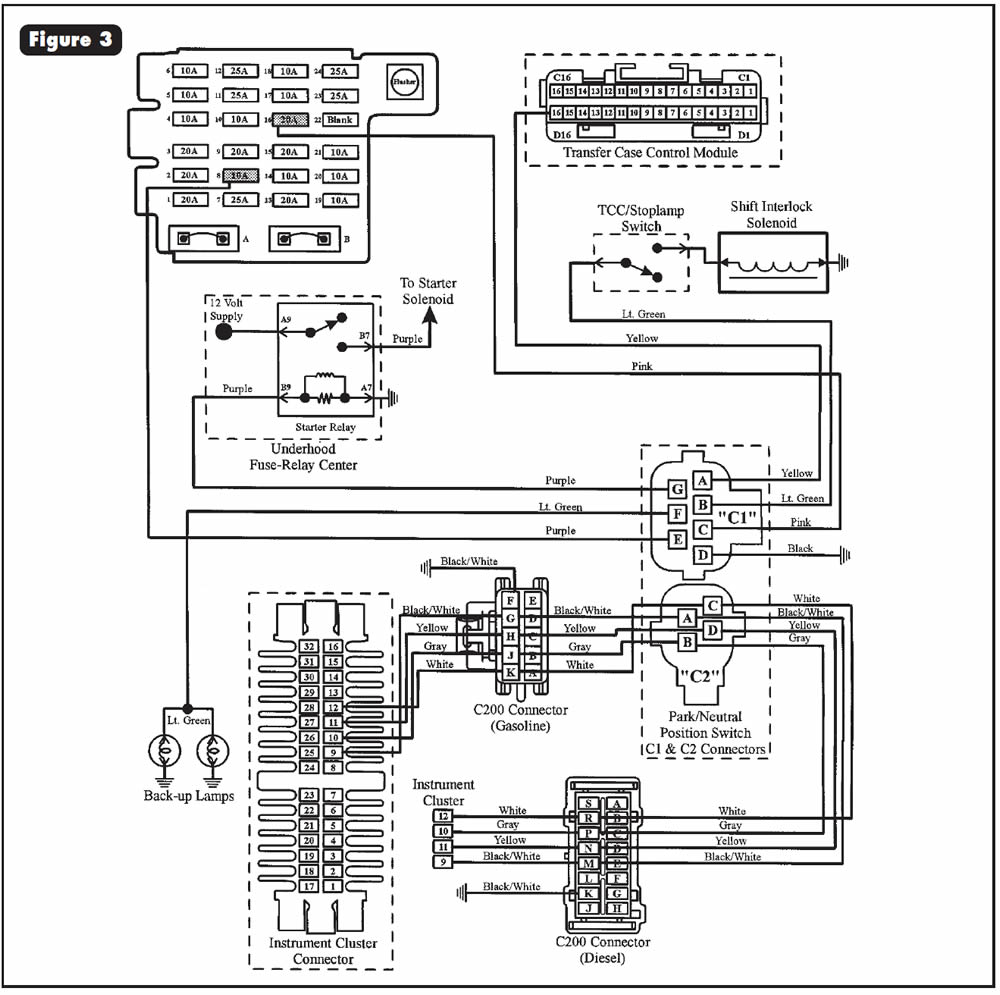

See Figure 3 for a full wiring schematic of the Park/Neutral position-switch circuit for diagnostic purposes.

- Park/Neutral Position Switch (All Models)……………………12450016

- 7-Way Repair Connector Assembly (Includes Heat-Shrink Connectors) ………..15305887

- 4-Way Repair Connector Assembly (Includes Heat-Shrink Connectors) ………..15305925

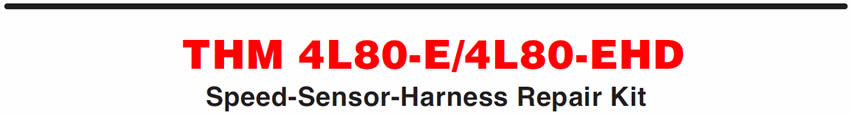

Now available from General Motors is a new Speed-Sensor-Harness Repair Kit, available under OEM part number 12101899, to fit all THM 4L80-E/4L80-EHD transmissions (See Figure 4).

We receive many phone calls wanting to know the location of the rear-lube seal and orificed cup plug in the THM 4L80-E transmission. We have shown the location of the seal and plug assembly in Figure 5.

Lube oil is fed through the orifice in the cup plug and into a passage in the extension housing to lubricate the extension-housing bushing.

Because four-wheel-drive models do not have an extension-housing bushing to lubricate, they will have a solid cup plug in this location. You must use extra caution if you happen to be changing the transmission case. If you were to install a four-wheel-drive case (with the solid plug) with a two-wheel-drive output shaft and extension housing, lack of lubrication would destroy the bushing in a very short time.

Always replace the orificed cup plug and lube seal on 2WD trucks.

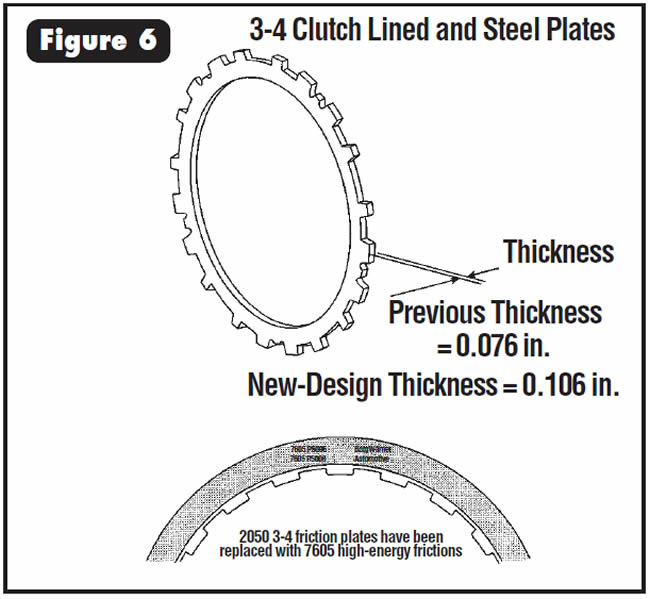

After rebuild, the vehicle exhibits premature 3-4 clutch failure, sometimes in as few as 2,000 miles of use. The complaint usually is associated with police, taxi or other heavy-duty use.

The cause may be not using the high-energy clutch plates and the thick (0.106-in.) steel plates, or not enough line-pressure rise with throttle opening.

Correction No. 1:

Install the latest-design 3-4 clutch pack from General Motors that allows the use of the thickest (0.106-in.) steel plates. This clutch pack requires the following:

(1) New-design 3-4 apply ring with shorter legs.

(2) New-design one-piece 3-4 apply plate.

(3) New-design 0.106-in.-thick 3-4 steel plates; 5 required (See Figure 6).

(4) New-design high-energy 3-4 friction plates; 6 required (See Figure 6).

(5) Thinner new-design 3-4 selective backing plate.

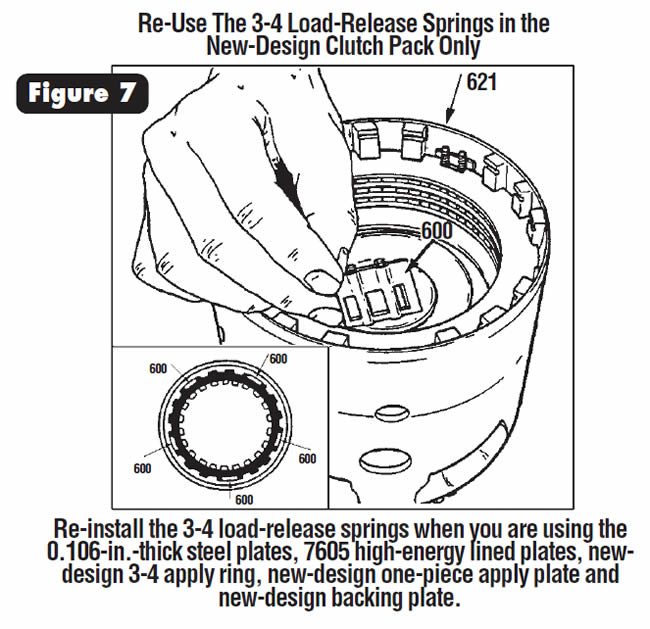

(6) Re-use of the 3-4 load-release springs in the late-design stack-up (See Figure 7).

(7) Ensure that you have 0.050-0.070 in. clutch clearance.

Correction No. 2:

Available from TransGo® is a new Vacuum Modulator Kit that does solve the concerns of line-pressure rise with throttle opening associated with the 4L60-E unit. This new kit replaces the EPC solenoid with a vacuum modulator and includes all necessary parts for the installation.

- 4 Clutch Apply Ring (New Design)…………8685043

- 4 Clutch Apply Plate (New Design)………..8685044

- 4 Clutch Steel Plates (0.106 in. Thick) …..8685045

- 3-4 Clutch Backing Plate (Selective 0.227 in., Stamped A)……8685046

- 3-4 Clutch Backing Plate (Selective 0.192 in., Stamped B)……8685047

- 3-4 Clutch Backing Plate (Selective 0.157 in., Stamped C)…..8685048

- 3-4 Load-Release Springs……………………….8667424

- 3-4 Clutch Friction Plates (High Energy) …………………………….24207605

- 3-4 Clutch Service Package (1987-1998) Includes the parts listed above, plus the 7605 friction plates……………………..8690923

Special Note:

The 2050 high-energy friction plates normally associated with the kit have been replaced with the 7605 high-energy friction plates for increased durability (See Figure 6).

After rebuild, the transmission will not upshift from first gear. Checking governor pressure with a gauge shows that it remains at 0 psi at all times, even when the solenoid harness is unplugged.

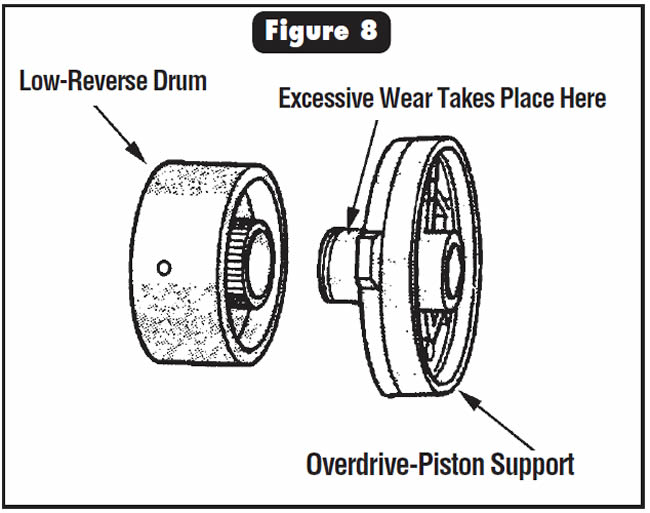

During overhaul, finding excessive wear on the overdrive-piston support where the low-reverse drum rides (See Figure 8) is not uncommon.

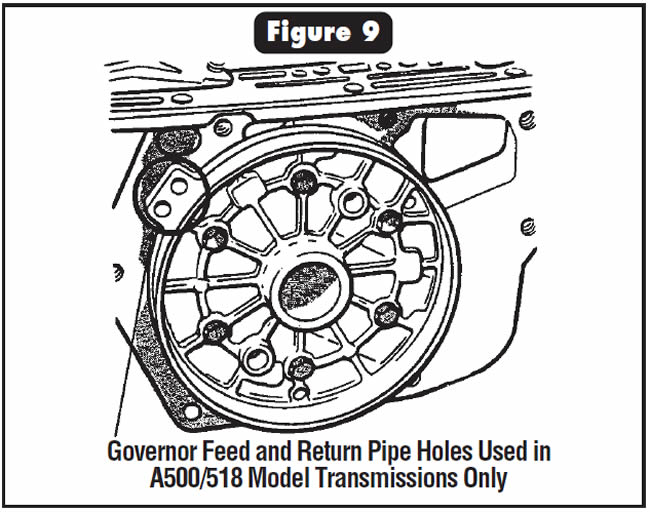

The worn support may have been replaced with one from an A500/518 transmission, allowing all governor oil to escape to exhaust. The A500/518 support has holes for the governor feed and return pipes. The 42RE does not use tubes, since governor pressure is controlled from the valve body by a solenoid (See Figure 9).

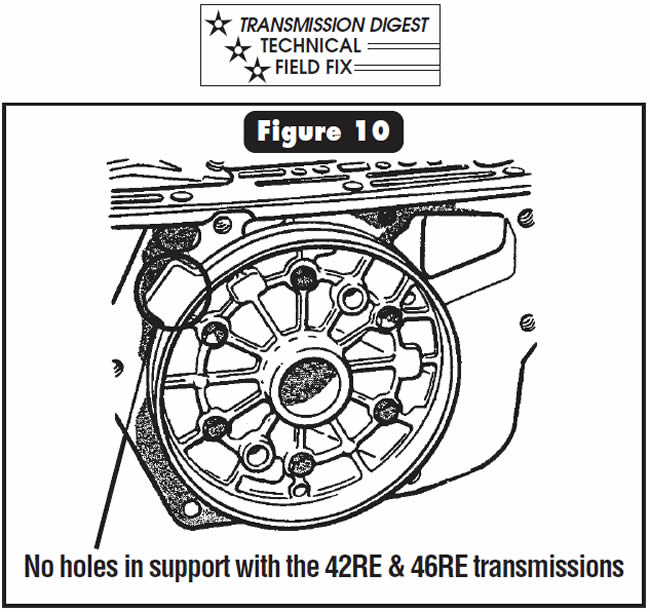

The support for the 42RE does not have these holes, so it blocks any governor oil from escaping to exhaust (See Figure 10).

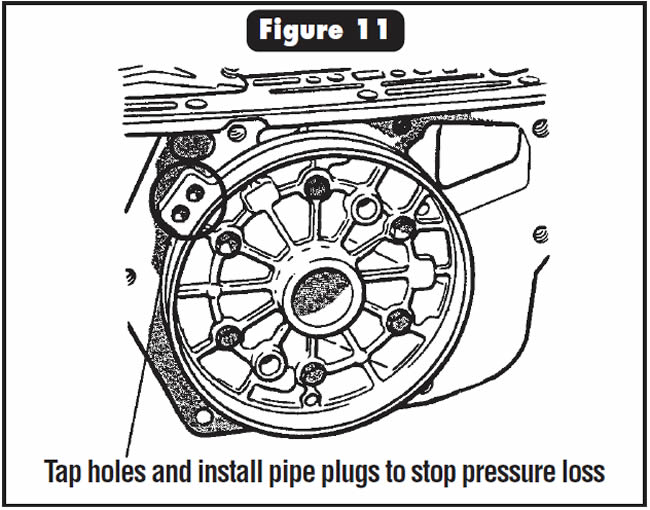

Replace the support with one from a 42RE transmission. In some instances, the overdrive extension housing can be removed from the transmission without removing the whole transmission from the vehicle. If this option is available, remove the over-drive section, carefully tap the two holes in the support and install pipe plugs, as shown in Figure 11.

After rebuild, some vehicles may exhibit a 1-2 upshift shuttle that can lead to misdiagnosis as a problem related to governor pressure or the valve body.

The cause may be that you have adjusted the intermediate band incorrectly or that the seal rings on the 1-2 accumulator piston are leaking.

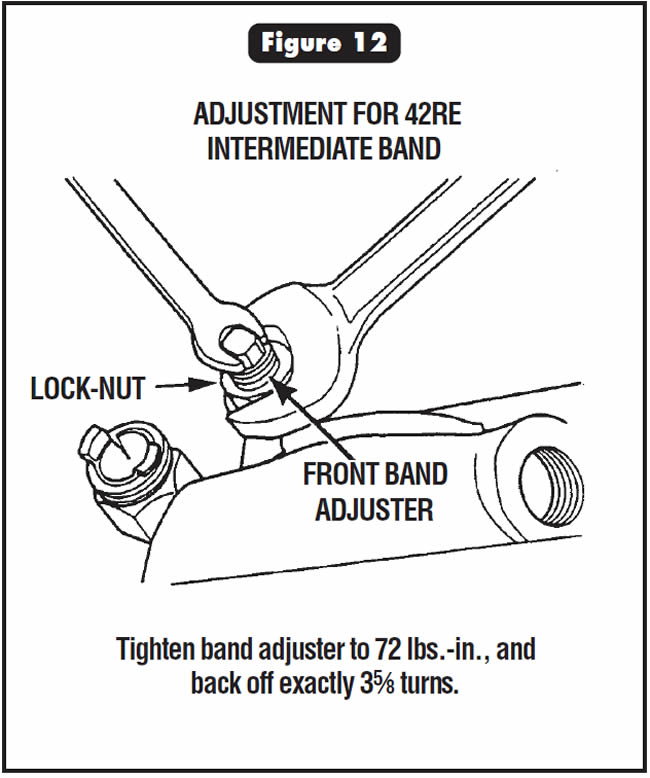

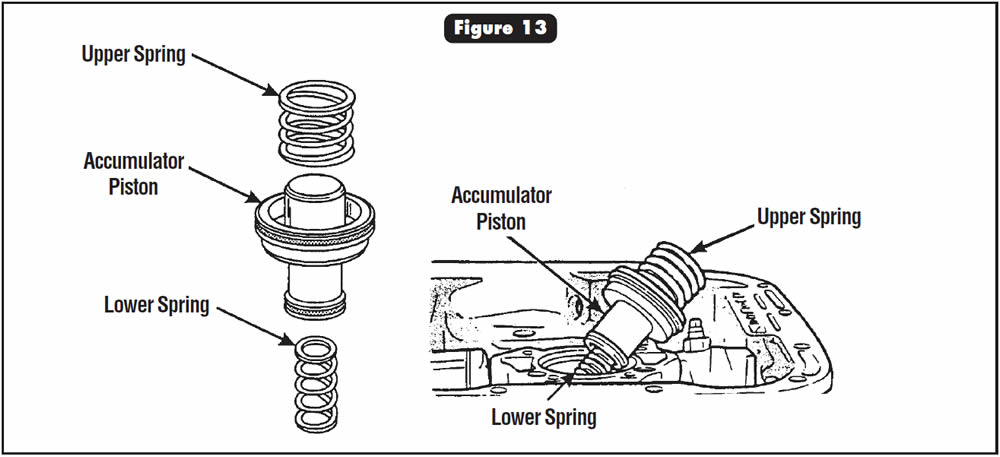

We have gotten into the habit of adjusting the intermediate band with a visual adjustment during the rebuild process before we install the bottom pan. This is a grave mistake on the 42RE transmission. You must tighten the adjusting screw to 72 lbs.-in. and then back off the adjusting screw exactly 35⁄8 turns (See Figure 12). In some instances we also have had to install the previous-design 1-2 accumulator piston with steel seal rings (See Figure 13).

August 2000 Issue

Volume 17, No. 8

- THM 4L60-E: Park/Neutral Position-Switch Connector Cannot Be Removed

- THM 4L80-E/4L80-EHD: Speed-Sensor-Harness Repair Kit

- THM 4L80-E/4L80-EHD: Location of Rear-Lube Seal and Orifice

- THM 4L60 and 4L60-E: Premature 3-4 Clutch Failure

- Chrysler A500SE(42RE): No Upshift After Rebuild

- Chrysler 42RE: 1-2 Shift Shuttle After Rebuild