It seems as though when any new transmission platform is released to the marketplace, sooner or later engineers get bored and start to tinker with various components. Although much of the new stuff that gets changed or upgraded concerns capacity, calibration or durability issues, other items are modified for less profound reasons such as the lowly filter.

There have been transmission designs that were initially developed to accommodate various vehicle models and remained in service for a decent stretch of time without getting a constant filter facelift, but those units seem to be few and far between. More often than not, the longer the unit is on the road the more likelihood a new filter version will show up. Newer filter-material technologies have been the cause of some of these changes and are certainly valid, although much of the time the new material can be incorporated into the existing filter body area.

When GM decided to develop the RWD six-speed transmission family, it was to accommodate a wide range of vehicles (cars and trucks) with several sizes of engines not only for the U.S. market but other markets around the world. With the exception of scale (size), the four basic models (6L45, 6L50, 6L80 & 6L90) look and smell pretty much the same with certain components that can interchange, although not many. One other concern is where the unit is actually produced, such as plants here in the states or over the pond in Strasburg. Beyond the units that are used in GM vehicles are the particular models used by BMW, which are primarily produced overseas.

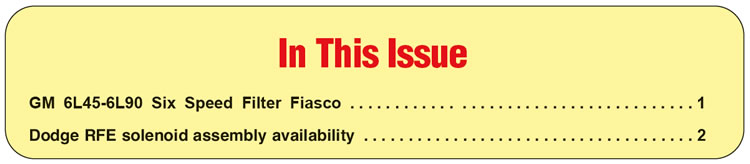

When it comes to the filters used in the RWD six speeds, there are currently six different part numbers to choose from some of which will overlap from one model transmission to another. The physical differences are not too extreme with one difference that begs the question, why? The size of the inlet will differ between filter part numbers although it’s not a major difference (Figure 1). Both inlets are rectangular with the short inlet approximately 1¾ inches long and the wide inlet approximately 2½ inches long.

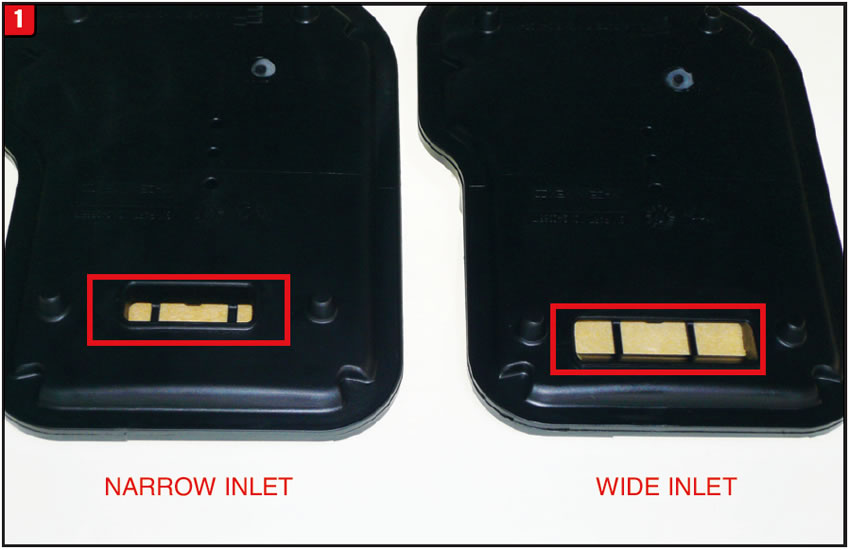

Another difference between filters involves the standoff (plastic tab) that is on the top side of the body of the filter (Figure 2). When the neck of the filter is pushed into the pump body seal, the tab of the filter needs to make contact with the valve body so that when the pan is installed it will not flop around and create a problem. The tab on the earlier filter applications is enclosed at the top as illustrated by the filter on the left, whereas, the tab on later applications is partially chopped off, creating a pitchfork look like the filter on the right.

6L45 Europe: The lightest duty model of the RWD family of six-speed transmissions is the 6L45, which is primarily produced in Strasburg and used by BMW. Anytime that a transmission is produced in a certain region, component suppliers are normally chosen from that area, in this case, Europe. Unlike the rest of the filters used by the 6L transmissions, the filter used in the 6L45 is a metal/plastic design which has been a mainstay in this country for years (Figure 3). The majority of the production of this design filter has been used by BMW for cars that would only require a shallow pan. Although this transmission was produced early on the locating tab (standoff) on the plastic side of the filter is the open or cut off style. The BMW OE part number, if needed, is 2411-759-3565, but fortunately the filter is available from the aftermarket.

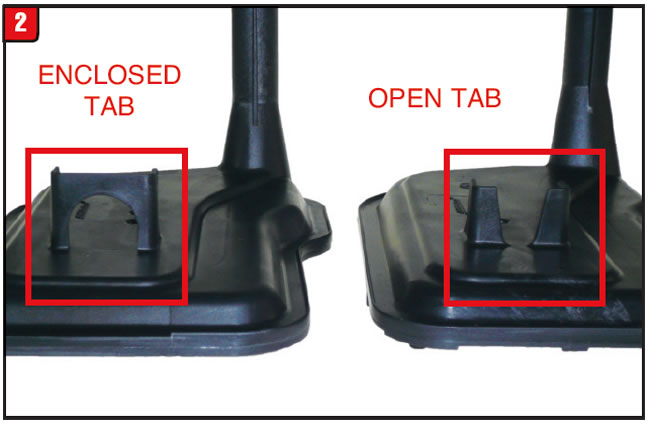

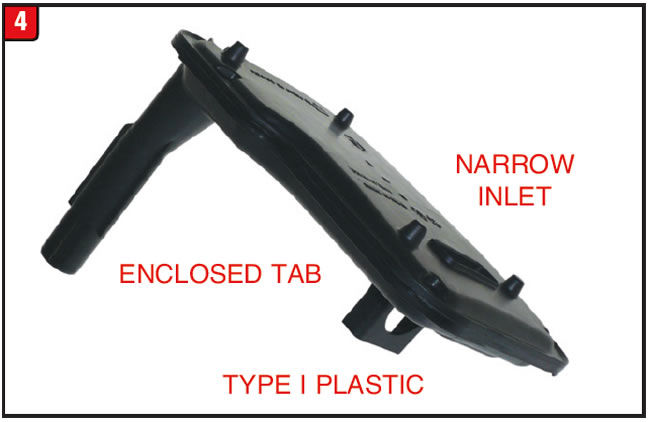

When it comes to filters that are produced state-side, it’s all about plastic. Regardless of application the five remaining filter part numbers are all plastic, which has been the trend for several years now. The issue is what the filters actually fit due to overlap of vehicles and transmission models. If the OE part number for the vehicle application is not readily available, then the next best approach is to go by physical description to avoid any clearance issues.

Type I Plastic: The first vehicle to receive a 6L80 was a 2006 Corvette and the filter used in that transmission could be considered Type 1 or the first design (Figure 4). The inlet used for this filter was the narrow version and the locating tab on the top side of the filter was the enclosed design. The depth of the pan must accommodate that type of filter. Other applications also use this type of filter, such as a 2010 to 2013 Camaro that is also equipped with a 6L80. The OE part of the filter is 24236931.

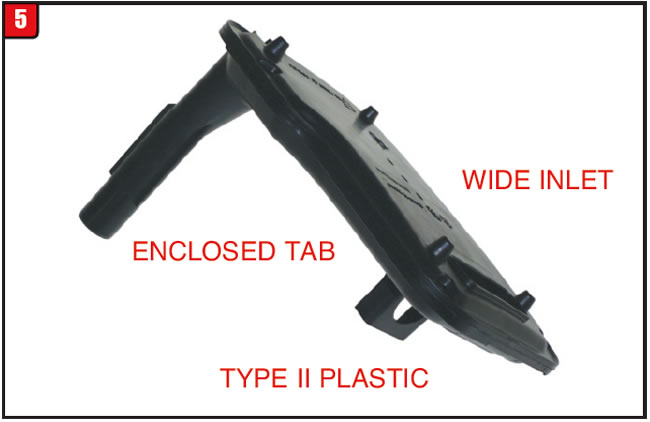

Type II Plastic: GM started to spread the wings of the 6L80 in 2007 by adding it to the truck line along with the addition of the 6L90, which is the beefiest model to date. Apparently, oil flow was a concern due to the fact that GM modified the inlet beyond the first design filter (Figure 5). It is questionable as to whether the Type I and Type II filters would interchange or not, but it would make sense that the wide inlet design would work for both. Various truck applications use this type of filter. The OE part number is 24236933.

Type III Plastic: The next filter in the lineup, chronologically speaking, could be considered somewhat of a freak due to application and design. Before GM pulled the plug on Pontiac a decision was made to add the new RWD six-speed transmissions to the line so in 2008 the Pontiac G8 was outfitted with a 6L50 or 6L80 depending upon engine size. For some reason the pan configuration used on Corvette was not sufficient for the G8, so things had to be tweaked a bit resulting in yet another filter (Figure 6). The locating tab on the top of the filter was cut off resulting in the pitchfork look and the bottom half of the filter has a rather shallow baffle that sur-rounds the inlet.

With the demise of Pontiac this filter part number normally would have been put out to pasture except for one thing, someone at Cadillac chose to keep it. In 2012 the Cadillac ATS was released with a 6L45 but instead of using the design from Strasburg like BMW, the all plastic version made here in the states was chosen. Who knows where else this particular filter could pop up. The OE part number is 24252158.

Type IV Plastic: Although there are several GM vehicles that come equipped with one or more of the six-speed transmission models, it seems as though Camaro uses just about all of them. GM decided to leave no stone unturned and in 2010 started to equip Camaro with one or the other based upon engine size. For applications using the 3.6L engine, the 6L50 was chosen, and of course, a new filter was needed (Figure 7). The inlet size chosen was the narrow type that was used on the 2006 Corvette but for some reason GM decided against using the Type I plastic design. Instead the top of the locating tab was cut off creating the pitchfork design and yet another part number to deal with. It is anyone’s guess as to why the original Vette filter would not work just as well. The OE number for the 6L50 filter is 24258268.

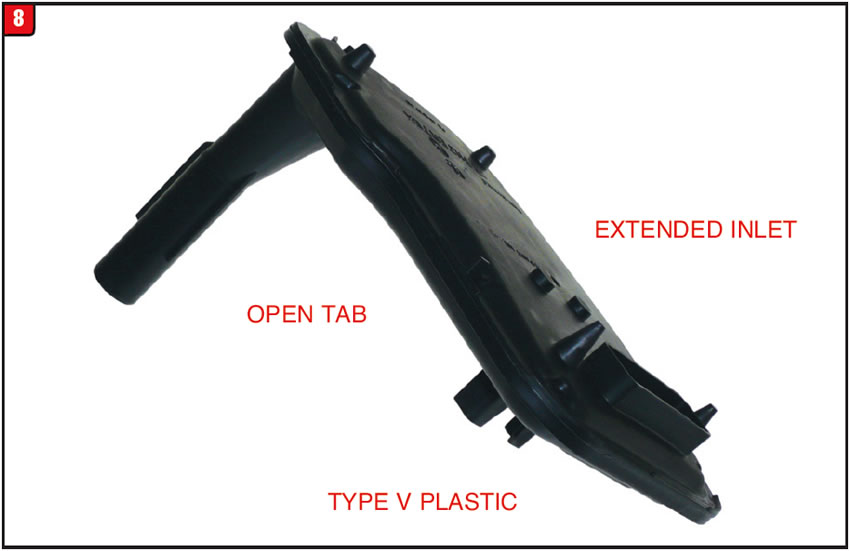

Type V Plastic: Lastly, GM decided that fluid capacity wasn’t quite sufficient enough for the 6L90 in certain applications so the pan was extended a bit to compensate and the filter was modified, yet again. Although the locating tab on the top side of the filter is cut down like the Type IV design, there is a ¼-inch lip around the inlet that happens to be the wide design as well (Figure 8). Using a shallower filter where this type is needed will result in a functional problem. Beyond using this in a 2012-up Camaro equipped with a 6L90, GM also uses it for a 2010-up Cadillac CTS. Time will tell where else it may show up. The OE part number for the deep design filter is 24258269.

All of this may be great in order to keep the engineering juices flowing, however it sure wreaks havoc for the repair industry. Easy access to part information would also be helpful.

When the 45RFE was launched way back in 1999, a good deal of engineering effort was put into the development of the solenoid assembly. Instead of placing individual solenoids at different spots around the valve body it was decided that all solenoids would be contained within one housing, as was done to previous transmission models.

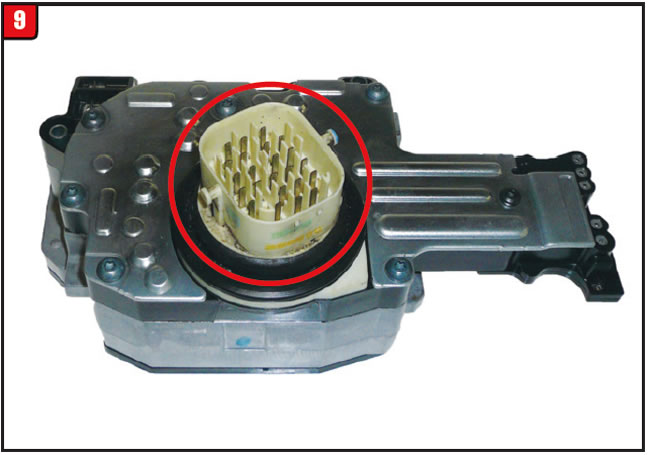

Solenoid assembly: The original solenoid block, which had a black plastic-case connector, was outfitted with solenoids that were not too traditional looking and after a relatively short period of time certain issues started to pop up that required Dodge to reinvent the wheel. Beginning in 2003 and bleeding into 2004, (Dodge and Jeep), a new solenoid assembly with more normal looking solenoids was phased into the vehicle lineup. The easiest way to discern the second design solenoid assembly was of course by the white plastic-case connector (Figure 9). The new design solenoid block also required a modified TRS plate, and Dodge released a service package containing both pieces that would retro back to 1999. The new setup seemed to address the issues that were caused by the black connector solenoid block, but nothing stays the same forever. The current OE part number for the kit is 68002342AD.

Whether due to a cost-cutting initiative or a more efficient approach to hydraulic apply of the overdrive clutch pack, a third design solenoid assembly started to show up in the vicinity of 2010. As usual, an upgrade such as this could not be completed in a respectable amount of time, say a month or two. Nope, this changeover has been slow going and model dependent. The easiest way to identify the new solenoid block is by the plastic-case connector, which is now gray. The OE part number for the gray-connector solenoid block is 52120000AA.

Unlike the first upgrade that occurred in 2003, the new gray-connector design resulted in changes to several other items, including computer strategy. The main tweak to the solenoid assembly has to do with the removal of the overdrive clutch solenoid (Figure 10). Beyond the color of the case connector (white or gray) the other difference in appearance concerns the housing itself, which happens to be the same raw casting used by both designs.

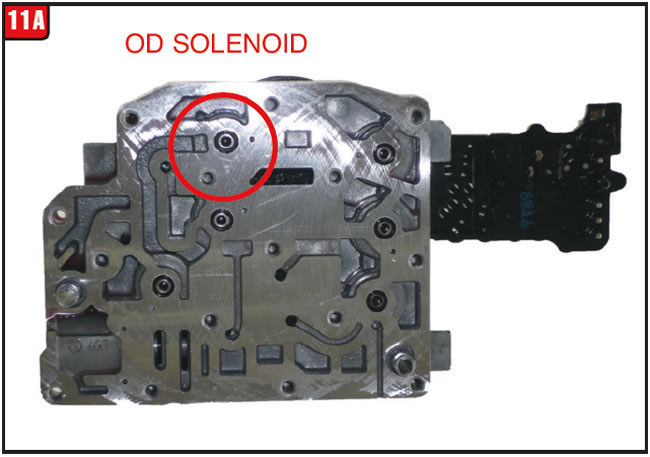

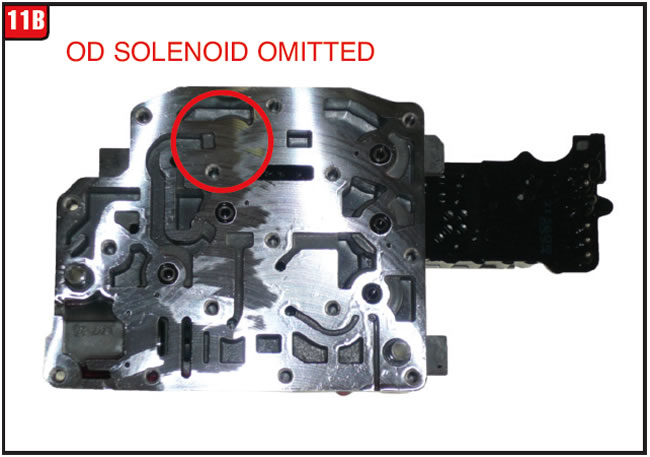

With the filter plate removed, the tips of the solenoids are exposed. The white-connector solenoid block has six visible solenoids, whereas the gray-connector solenoid block is not drilled for the overdrive clutch solenoid (figures 11A and 11B). At least the filter plate is the same between both models.

One purpose behind all of this is control of the overdrive clutch. The white-connector solenoid block could not only apply the overdrive clutch with the overdrive solenoid, but also with the multi-select solenoid as well, which is somewhat redundant. The gray connector solenoid block only uses the multi-select solenoid to apply the overdrive clutch pack which apparently gets the job done.

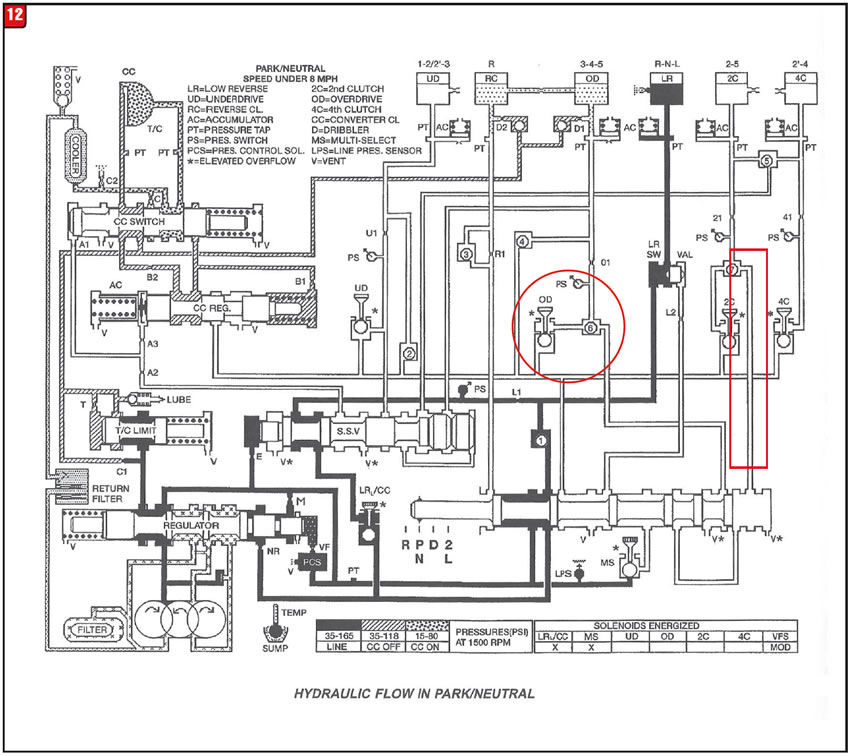

Another focus of this change has to do with manual shift control. Transmission operation with the white-connector design provides a manual control comparable to older transmissions, whereas the gray-connector design provides a tap shift function. When viewing an oil schematic, notice the areas affecting the overdrive clutch and second clutch apply (Figure 12). Not only will the overdrive clutch solenoid and #6 check ball be removed, but the manual valve oil passage that feeds the second clutch and #7 check ball be removed as well.

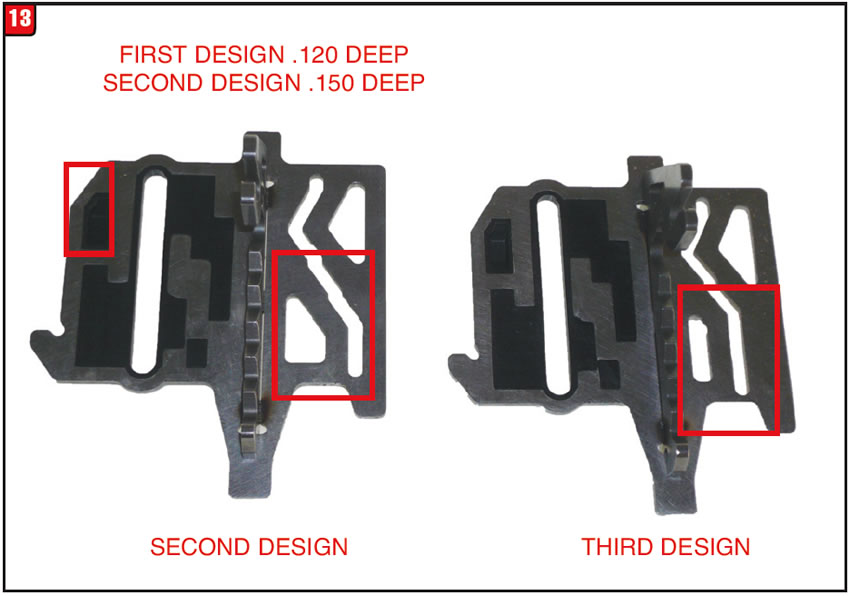

TRS plate: One item that goes hand-in-hand with the solenoid assemblies is the TRS (transmission range sensor) plate. The first design TRS plate that was used with the original black connector solenoid block is NLA. The second design TRS plate that was released with the white connector solenoid is still available under part number 4799654AC. The TRS pin pocket is deeper on the second design plate (0.120 vs 0.150). One other area of the plate that matters relating to the third design is the groove that controls the manual valve. The extra bend in the second design groove is what provides manual 2 & 1, which is why it must be used with the correct type of valve body (Figure 13).

The third design TRS plate was designed to be used with the gray-connector solenoid block and the part number is 52119998AA. Although the new plate was released at the same time as the gray connector solenoid block, the main concern is that it is used with the redesigned 2010 and later valve body regardless whether the white or gray-connector solenoid block is used due to the manual valve groove. For years the white-connector solenoid assembly was the only option when replacing the gray connector design solenoid.

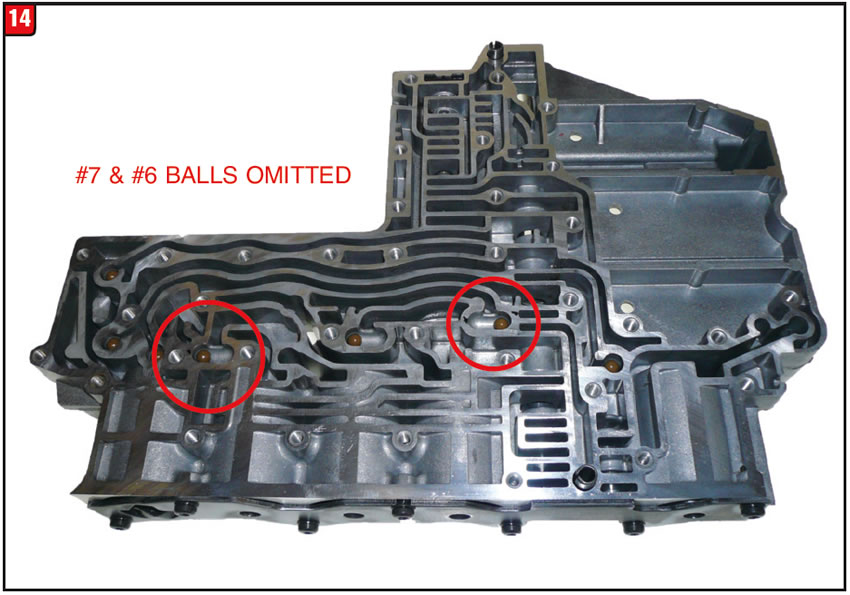

Valve body: As a result of modifying how the over-drive clutch was applied, the valve body had to be addressed to accommodate the change. Fortunately, changes to the valve body were somewhat minimal but important nonetheless. The best way to determine the design level is by the number of check balls used. The valve body that is used with the previous manual shift strategy has seven check balls (Figure 14). The new tap shift version only uses five check balls due to the #6 & #7 balls being omitted. The pockets for those two check balls are still in the casting however. The manual valve was also modified and now has an extra land that includes an ID notch.

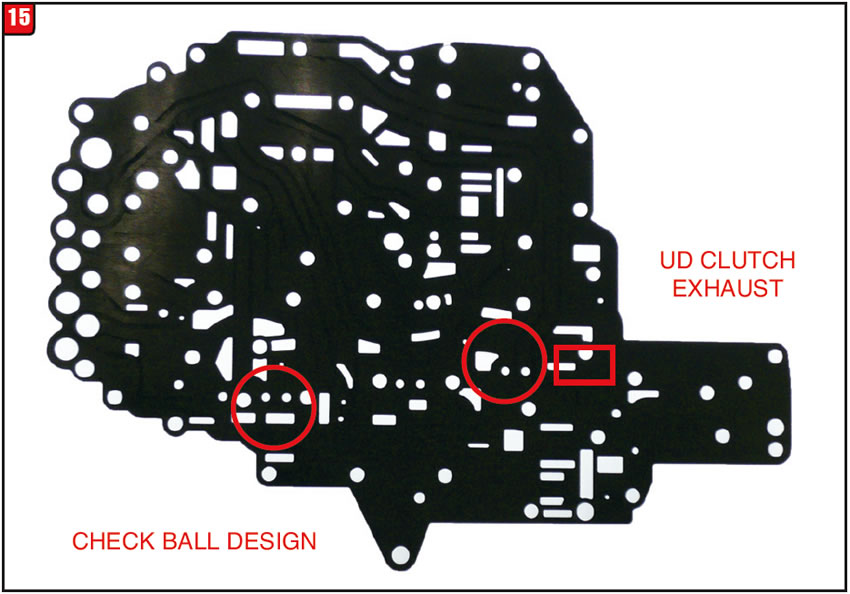

Separator plate: The remaining item that must match the design level of the other components is the valve-body separator plate. The earlier design separator plate could have a stamp number of 545AB, but other stamp numbers may exist. The best way to discern the separator-plate design is by looking at the holes in the plate above the #6 & #7 check ball bathtubs (Figure 15). If there is a hole at each end of the bathtub, then a check ball is required and the plate is the previous design.

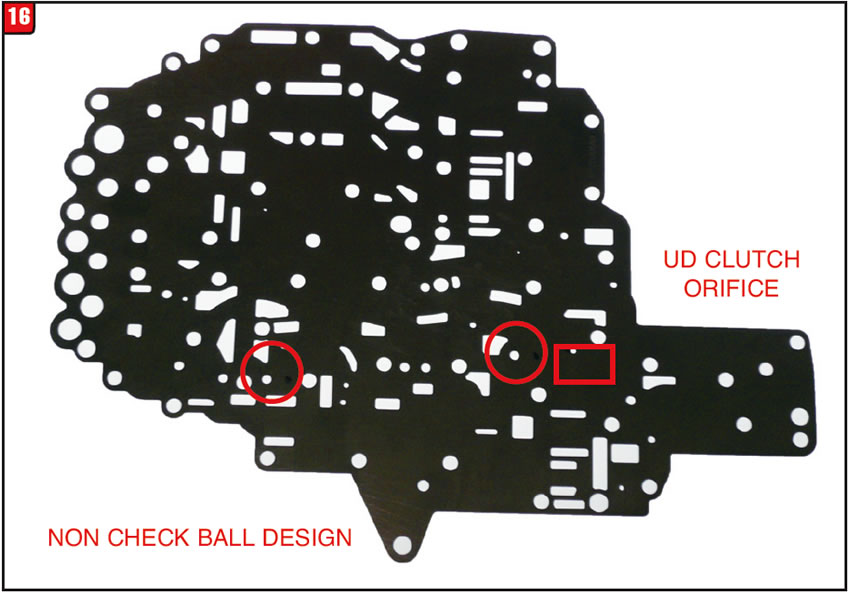

If there is only one separator-plate hole above both bathtubs, then it is the newer design plate and no check balls are required. The OE part number for the newer separator plate is 52120004A. Speaking of separator plates, a problem had surfaced concerning vehicles newer than 2010 relating to a noise while shifting from drive to neutral. The issue was due to the underdrive clutch releasing to quickly which ultimately created the noise. The fix merely involves replacing the previous second-design separator plate with what can be now considered a third design. The way to identify the new plate is by the addition of an orifice hole (Figure 16). The OE part number of the newest plate is 52120004AB which can be used to service any of the 2010 and newer vehicles with a five-check-ball valve body.

Until recently, the gray-connector solenoid assembly was not available from OE and a shop had to purchase the white-connector design instead. Currently, the gray-connector solenoid is available from Dodge although availability could be spotty. In addition, the gray connector is substantially less costly than the white connector, which is a plus.

For vehicles that are 2010 and later with the new-design shift strategy, both the white and gray solenoids are listed by Dodge for those applications; however, only the third-design TRS plate is listed due to the valve body compatibility. Why this has taken so long is anyone’s guess, but at least it’s handled now.

April 2017 Issue

Volume 34, No. 4

- GM 6L45-6L90 Six Speed Filter Fiasco

- Dodge RFE solenoid assembly availability