Issue Summary:

- The 341E type of valve bodies used in various Toyota, Lexus and Volvo models look alike but are very different and are not interchangeable.

- Before or after an overhaul, a vehicle equipped with the RL4FO3A/V transaxle will not upshift after warm-up.

- Nissan Quest/Mercury Villager models may exhibit persistent codes for the throttle-position and/or vehicle-speed sensor.

- Ford Motor Co. vehicles with the 5R55N/5R55W can experience delayed or no engagement that is more frequent when the transmission is cold.

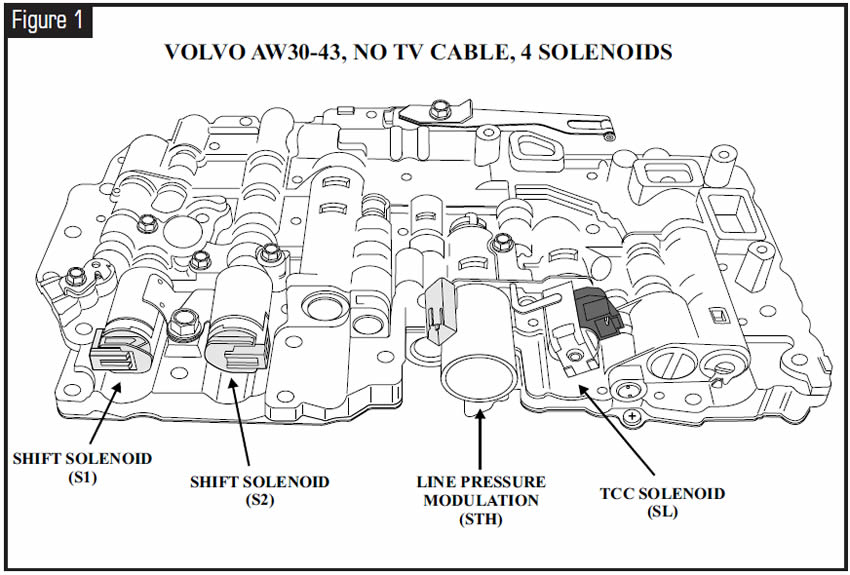

The 341E type of valve bodies that are in various Toyota, Lexus and Volvo models appear very similar but are very different and are not interchangeable.

The reason for this is that two of the valve bodies have four solenoids but only one has provisions for a throttle cable. The other valve body has five solenoids and no throttle cable. In addition to that, the solenoids may appear the same, but one controls line pressure and the additional solenoid controls accumulator backpressure.

Figure 1 shows the valve body for the 1993-97 Volvo 960 and 1997-98 S90 and V90 AW30-43LE. It also identifies the solenoids.

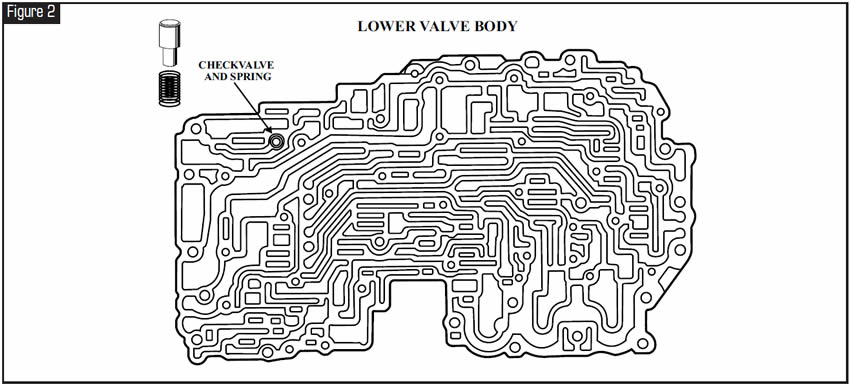

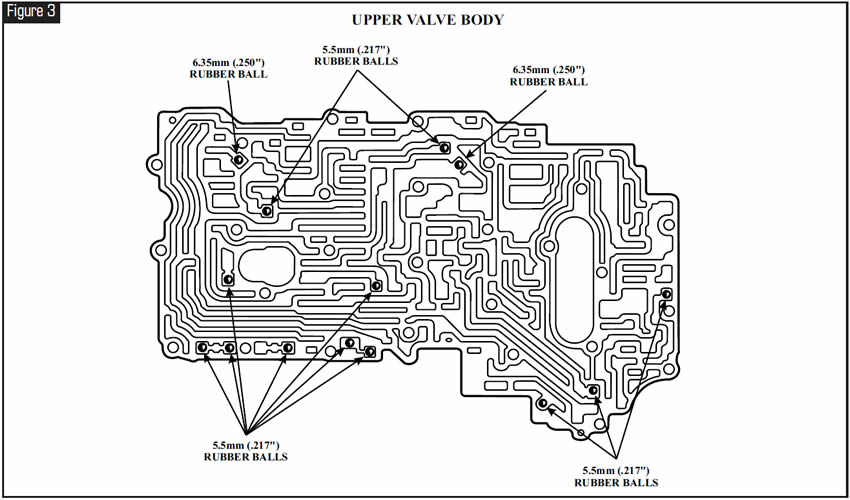

Figures 2 and 3 identify checkball and small-parts locations. These vehicles use a separate TCM to control the transmission.

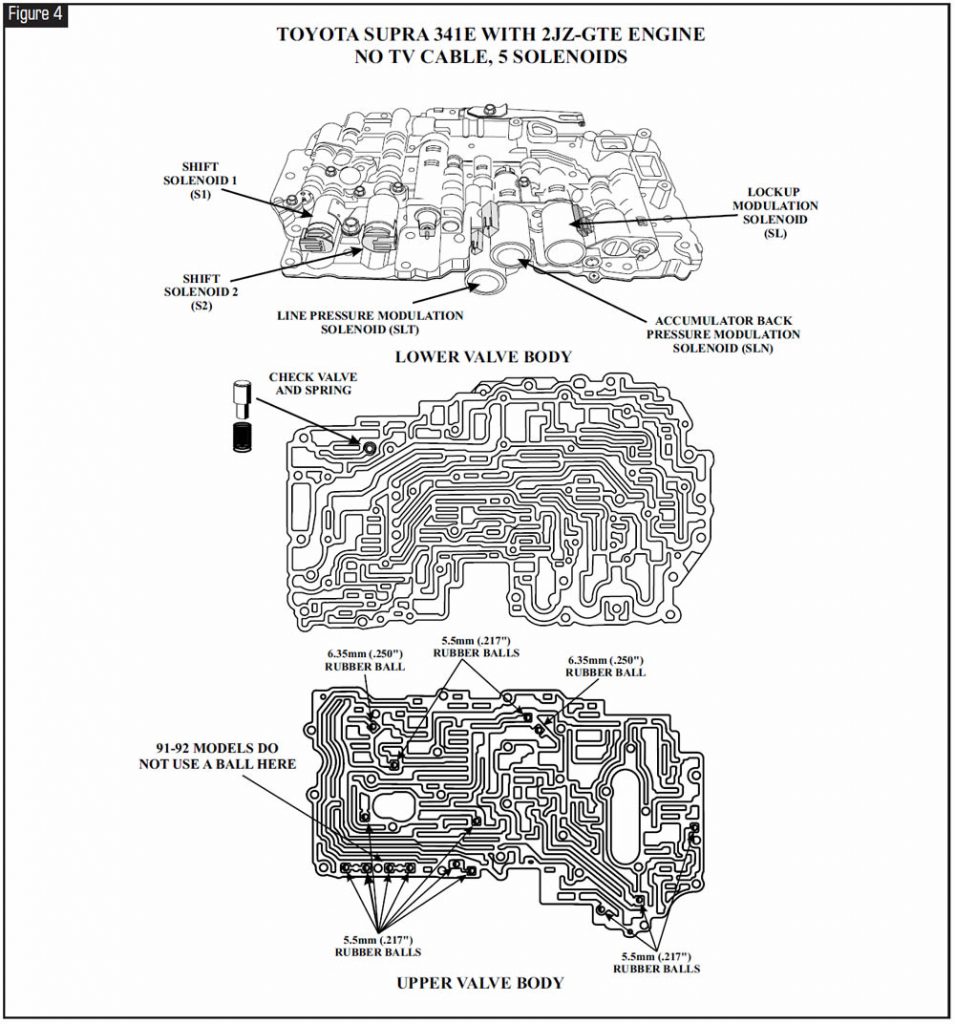

The valve body in Figure 4 is for the 1993-98 Toyota Supra Turbo with the 2JZ-GTE engine only, 1998 Supra Non-Turbo and 1998-00 Lexus SC300. These vehicles use a PCM to control the transmission and the engine.

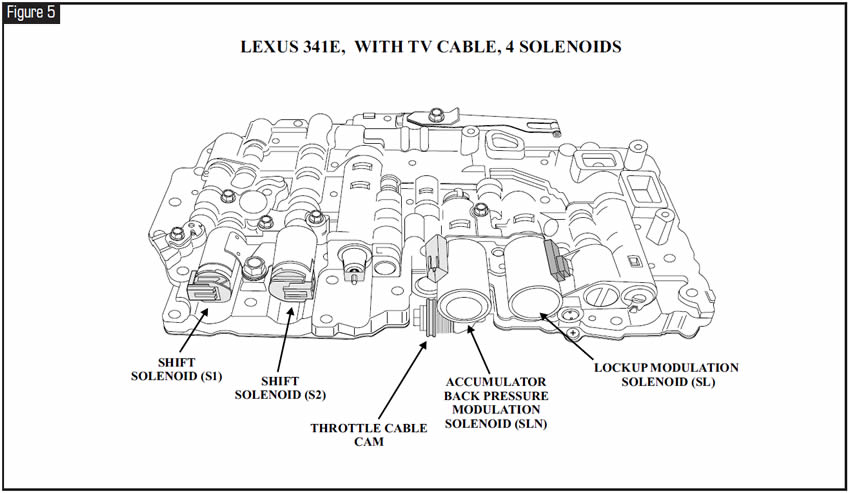

The valve body in Figure 5 is the Lexus 341E version, which can be found in various Lexus models from 1991 to 1997.

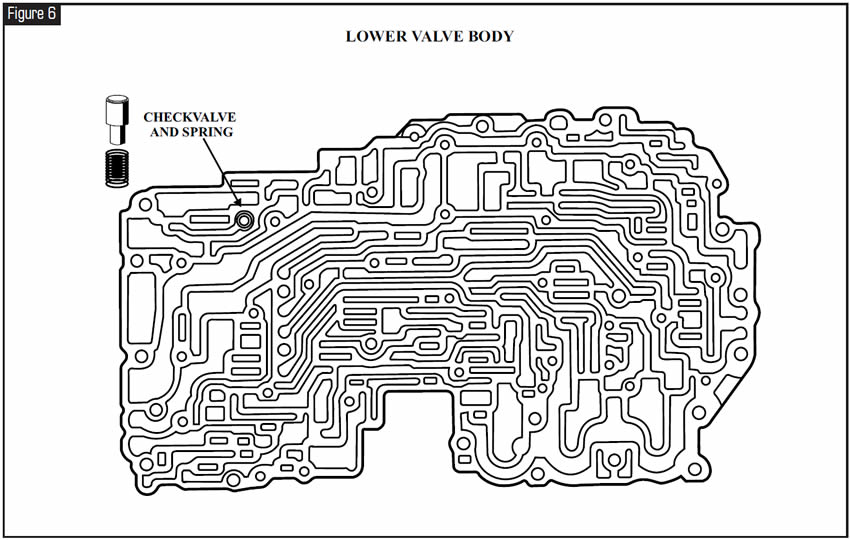

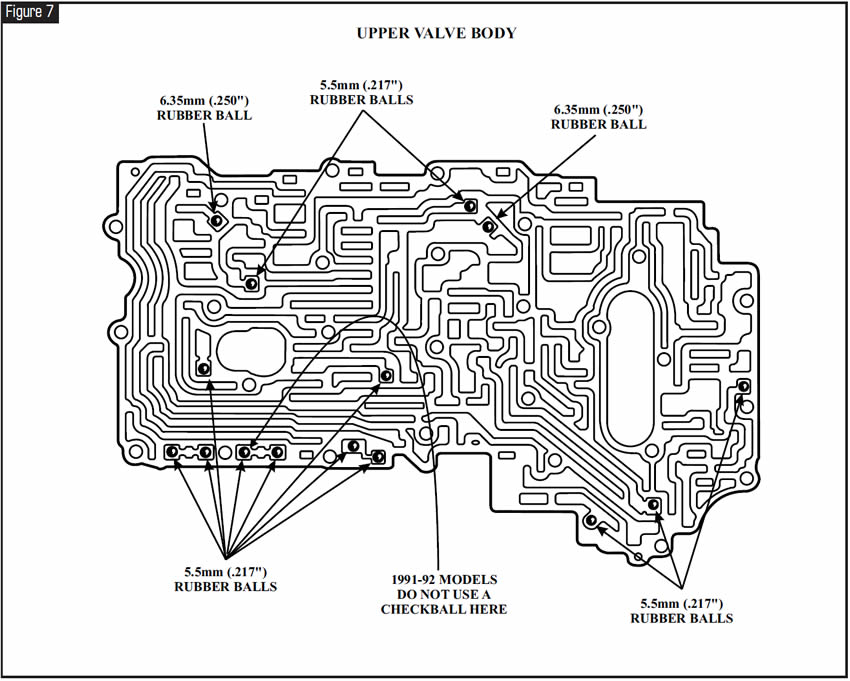

Figures 5, 6 and 7 identify the solenoid, checkball and small-parts locations. This valve body also has four solenoids but uses a throttle cable for line-pressure control. A PCM is used to control the transmission and the engine.

Note:

All of the transmissions that use the valve bodies described here have an overdrive direct-clutch-drum speed sensor.

Before or after an overhaul, a vehicle equipped with the RL4FO3A/V transaxle will not upshift after warm-up.

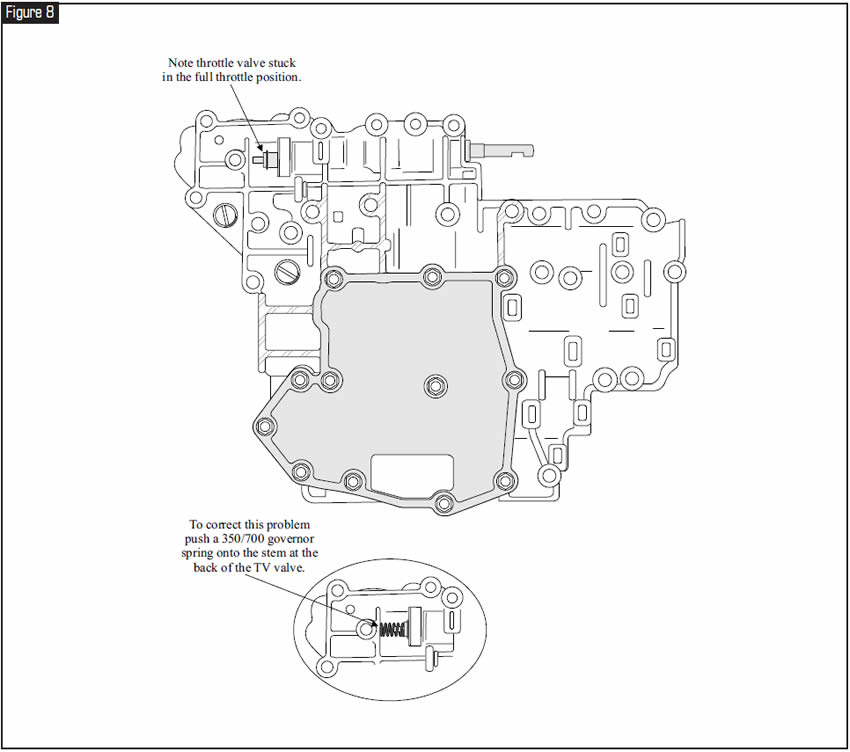

One cause may be that the throttle valve in the valve-body assembly is becoming stuck, or sucked in hydraulically. You may notice that when this condition occurs, the throttle cable by the throttle body shows excessive slack.

This condition is fairly simple to correct, as valve-body removal is generally not necessary. Remove the transmission oil pan and slide a 350/700 governor spring over the stem on the back side of the throttle valve as shown in Figure 8.

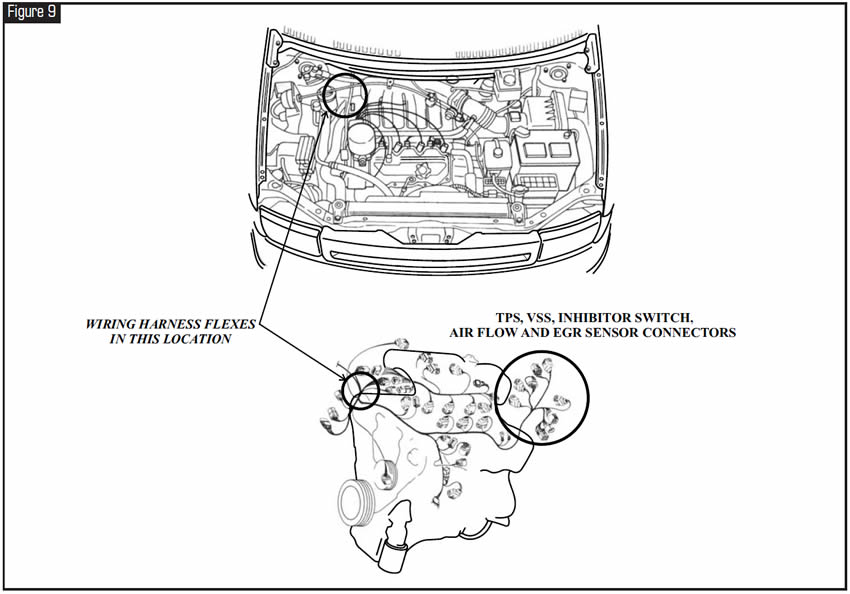

Persistent codes for throttle-position and/or vehicle-speed sensor. This complaint also may be accompanied by stored air-flow-meter or EGR-sensor codes in the engine computer. Intermittent inhibitor-switch malfunctions also may be noticed.

Lower engine mounts have been known to soften or break, allowing excessive engine rotation with increased torque. If this engine-rotation condition is permitted to continue over a long period, it allows for a junction in an engine-compartment wiring harness containing the TPS, VSS, EGR, AFM and inhibitor-switch wiring circuits to flex frequently (see Figure 9). As a result, these wires become fatigued and compromised, producing erratic and chronic faults.

Repair the mounts and the damaged wire or wires related to the complaint.

Vehicle arrives with a complaint of intermittent delayed or no engagement. May occur only during extreme cold-weather conditions. The transmission may engage when throttle is snapped open and operate fine until the vehicle cools down and is restarted.

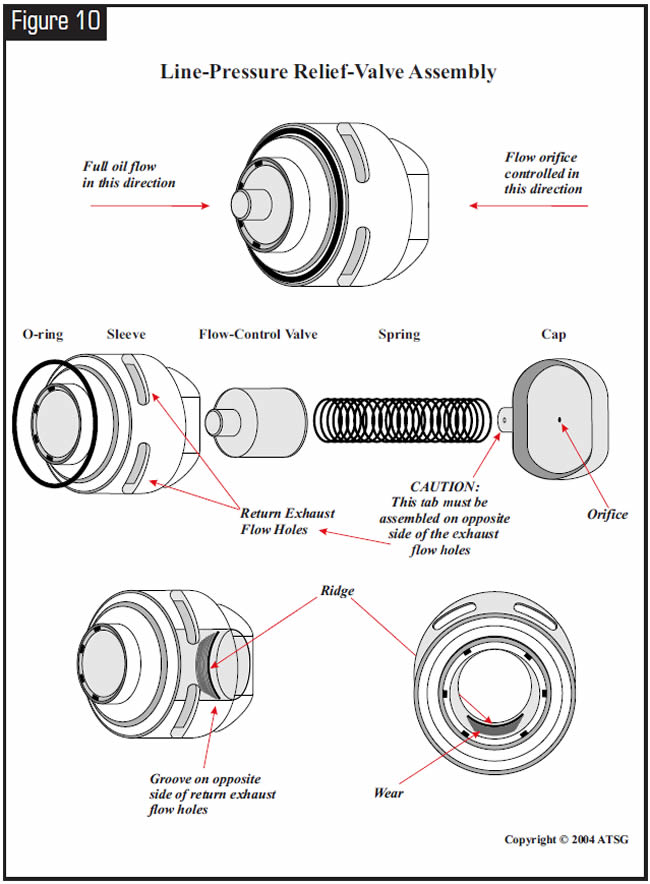

Line-pressure relief-valve assembly (flow-control valve) in the pump stator stuck in the open position because of extreme bore wear in the relief-valve sleeve. Another cause would be oil bypassing the O-ring between the pump plate and relief-valve sleeve.

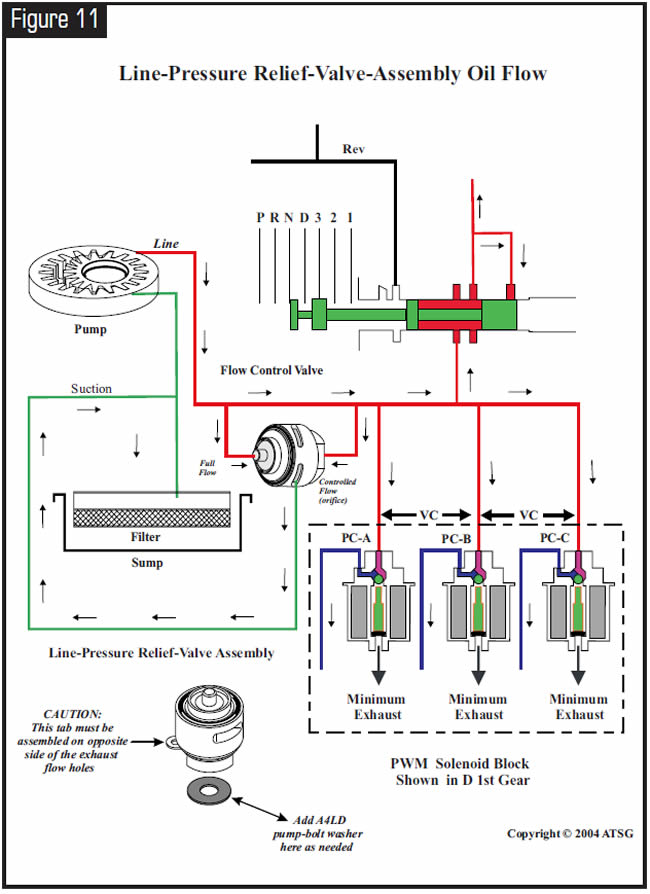

At this time no replacement for the valve and sleeve is available separately in the aftermarket or from Ford Motor Co. A complete pump assembly is available from Ford and from aftermarket hard-parts suppliers. Figure 10 points out the area prone to wear that causes the valve to stick in the open position. The hydraulic diagram in Figure 11 will show how the oil in the circuit coming from the pressure side of the pump will follow the path of least restriction.

If the valve were to stick in the open position, the oil would return to the suction side of the pump. There would be no oil pressure throughout the rest of the unit’s hydraulic system. The same would result if the oil leaked past the O-ring between the pump plate and sleeve. This O-ring is thin and therefore has very little compression against the pump plate. Adding one or two A4LD pump-bolt washers to the back of the sleeve would help to compress the O-ring, resulting in a tighter seal.

April 2004 Issue

Volume 21, No. 4

- Toyota 341E Volvo AW30-40, 30-43LE: Valve-Body Identification

- Nissan RL4FO3A/V: Won’t Upshift When Warm

- Nissan Quest/Mercury Villager: Harness Fatigue

- 5R55N/5R55W: Delayed or no Engagement; More Frequent When Cold