Technically Speaking

- Subject: New method for checking circuit integrity in valve bodies

- Essential Reading: Rebuilder, Diagnostician

- Author: Wayne Colonna, ATSG, Transmission Digest Technical Editor

I am sure that all of us who are in our late 40s and older can agree that valve bodies today are not what they used to be. Bore wear, valve wear, sleeve wear and leaking bore plugs are frequent ailments in most transmissions today.

Thanks be to several aftermarket companies that have developed repair kits to overcome these hurdles, saving transmission shops the expense of a new valve body. In fact, because these repair kits are so extensive (because of extensive valve-body problems) and span several manufacturers, a new type of business has emerged in our industry: valve-body reman facilities. All this has helped and continues to help the shops by providing an alternative to an otherwise more-expensive option. But there can be a pitfall here. What seems to happen more times than not is what is known as a pattern-failure repair. In other words, one may say, “Oh, this valve wears out the bore all the time, so let’s replace it.” And it is replaced without being checked to see whether it really had a problem. This type of unnecessary expense can tally up quickly, especially if the problem is thought to be resolved by this repair and the real problem – which is lurking elsewhere in the transmission – is overlooked.

Besides the obvious reason of repeated common wear problems in valve bodies, what contributes to this type of pattern-failure repair is the difficulty in checking a valve body to see what it really needs. Methods such as the wet air test or vacuum test have been developed as a means of diagnostics to determine the required repair.

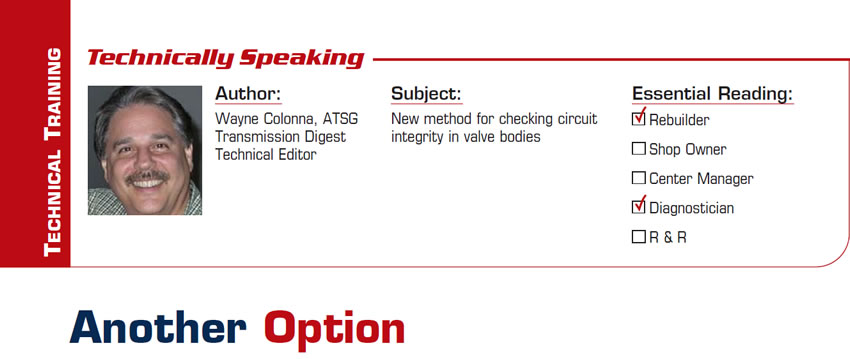

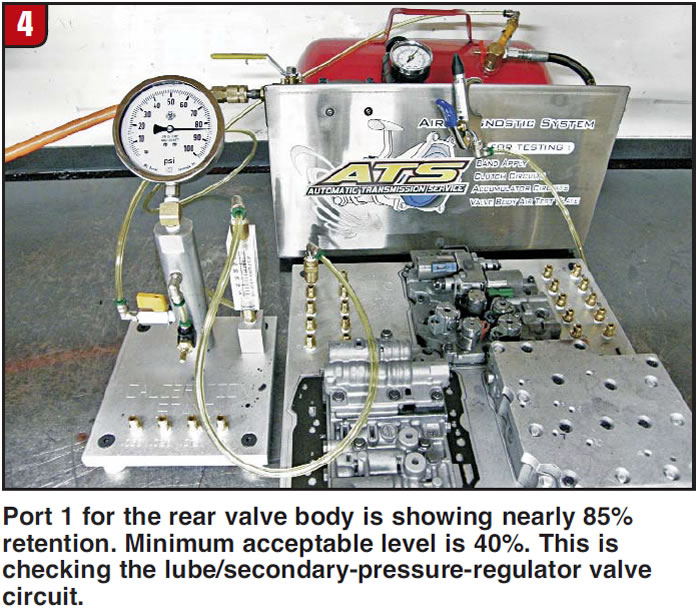

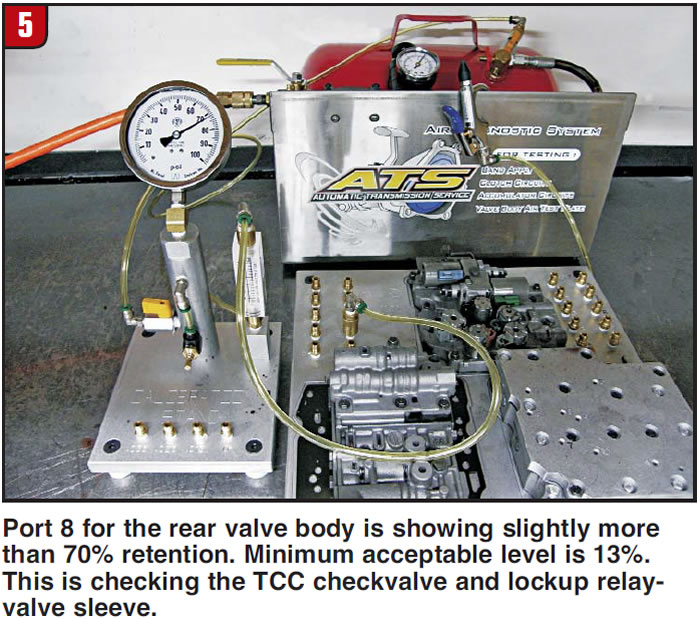

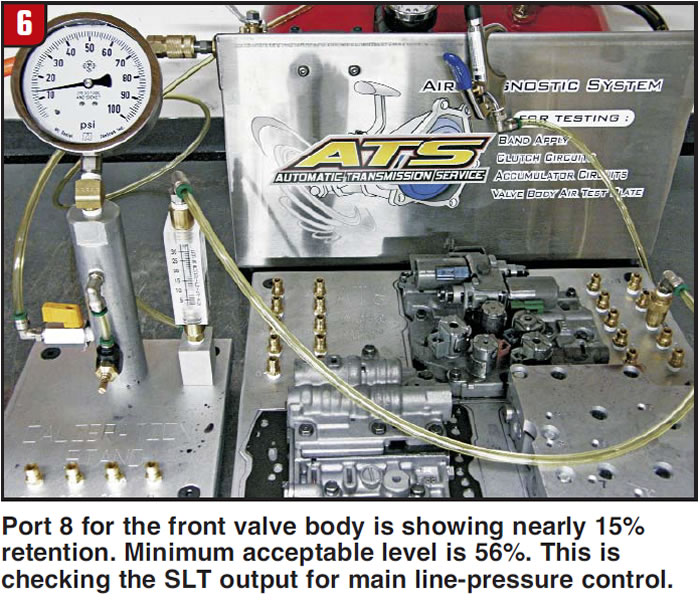

There is now another option. It is a circuit air-test plate, made by Automatic Transmission Service, called the Air Diagnostic System. The way the system is designed, it allows you to break down the valve body and mount it on the test plate. The valve body does not need to be cleaned, nor do the checkballs or checkvalves have to be installed.

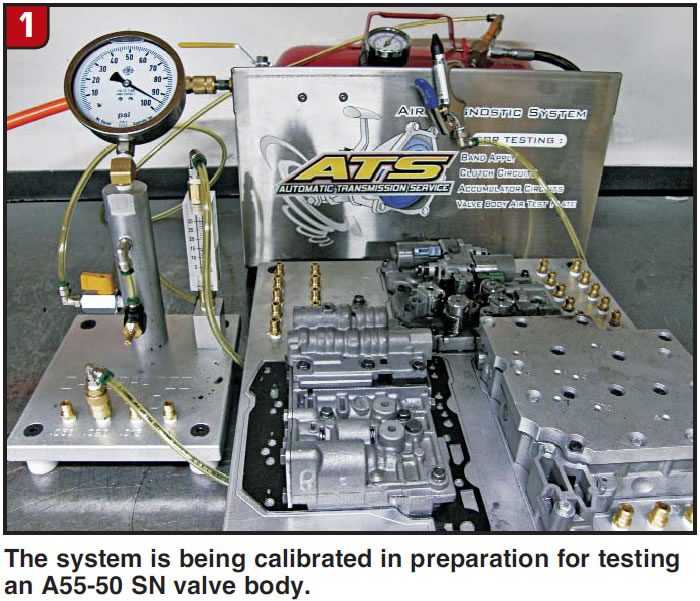

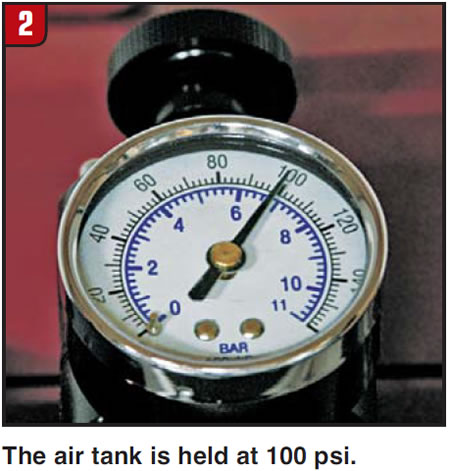

There is a simple manifold-calibration and leak-down test to be performed on the equipment before testing so that the test-stand gauge will provide an air-pressure value that is equivalent to the percentage of retention. Once the system is calibrated, compressed air is used to isolate one valve bore at a time. The pressure reading obtained on each test port is logged and compared with a chart provided for the specific valve body being tested. The chart lists a value of what is considered good for each circuit, so the numbers logged quickly provide pass/fail data.

After testing all circuits, you know what it will take to make that valve body right. Besides verifying a problem and improving estimates, this air-test plate also can be used as a visual sales tool. Volume repair facilities use the system both at tear-down and then again after repairs prior to assembly.

In summary, three methods now are available to the shop to determine what type of investment is needed in the repair or replacement of a valve body. They are:

The wet air test

The wet air test requires a flat piece of plexiglass with a port to pass air through and a working knowledge of how and where to trap and test a particular circuit.

Vacuum test

This requires a complete cleaning of the valve body, a vacuum tank and gauge, and a working knowledge of how and where to trap and test a particular circuit.

Air diagnostic system

This requires the acquisition of an air tank, test-stand gauge and a circuit air-test plate for each valve body requiring testing.

Of course, there are visual methods of checking valve bodies such as the LED-light leak test, valve wobble or sag test, but it is one of the three previously mentioned testing techniques that can reach into areas that lights, wobble and sag cannot. By learning to be proficient in testing a valve body, you can reduce the cost in repairs by buying only what you really need. The system-failure repair mode may be a bigger black hole than you realize.