Shift Pointers

- Author: Pete Luban

A 1997 Ford E 250 van equipped with a 4.2-liter engine and a 4R70W transmission comes into the shop with a complaint of falling out of fourth gear into third at highway speeds. In local traffic, however, the transmission acts like a C6 with a stuck governor; it remains in second gear as you come to a stop and “dunks” down into first gear.

The technician hooks up the scan tool to check for codes that might provide a clue that will eventually lead to the cause of the problem. To the technician’s surprise, no codes are stored. The technician knows this has to be electrical, because the scan tool told him that the computer was commanding the downshift to third gear.

Upon viewing the transmission data list, he noticed that the scanner was showing the manual-lever position as D2, and when he checked the voltage at the manual-lever position sensor (MLPS), it indicated 1.36 volts. This is a D2 voltage indication!

This is a very busy shop, so the technician installed a new MLPS (who doesn’t keep at least one MLPS in stock?). The new MLPS made no difference; all symptoms remained the same.

One important piece of information that you will need to know is that this van had just come from a general-repair shop that had installed a used engine.

A lot of times when this type of work is done, a number of wiring-harness hold-down points are not reattached; that was the case here.

As the technician got further into his diagnostic routine, the problem seemed to lead toward the front of the vehicle.

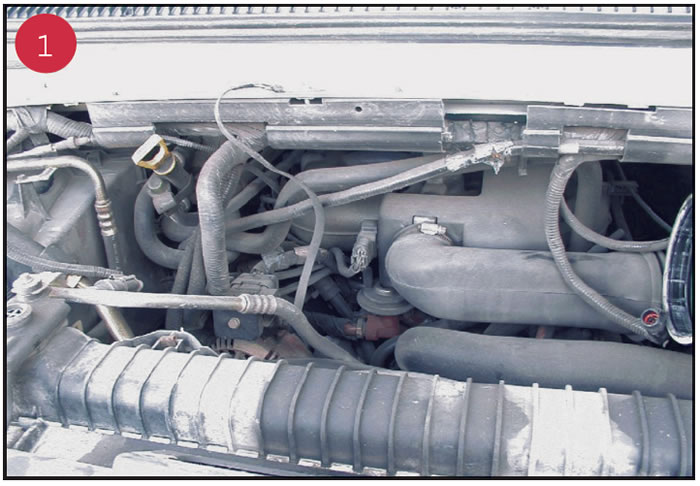

Figure 1 shows where the problem is. Doesn’t look very inviting, does it?

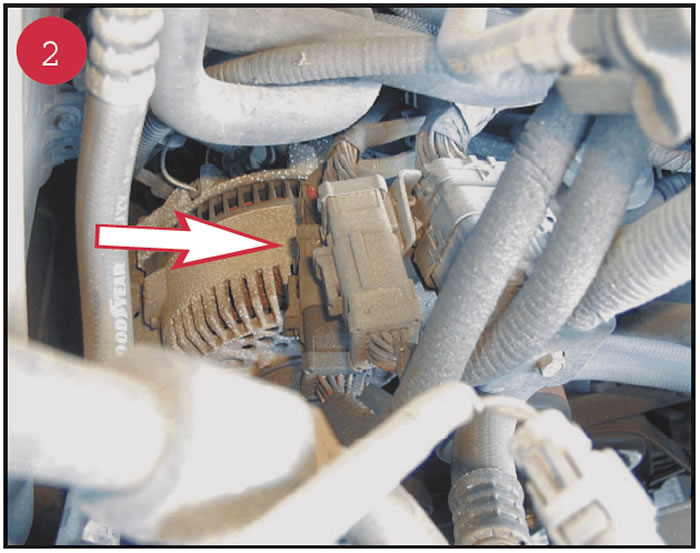

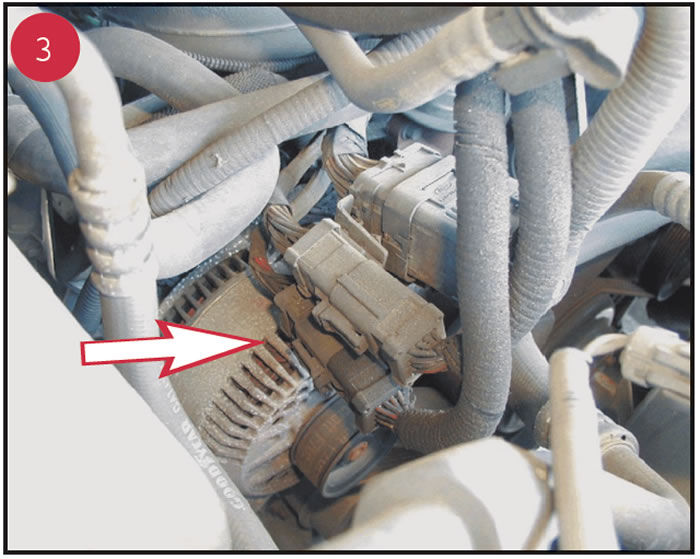

The arrows in figures 2 and 3 point to the cause of the problem. It seems that the wires in the connector indicated by the arrow had not been attached to their hold-down brackets; they were just lying on top of the alternator. The wires in this connector include those that carry the MLPS signal to the powertrain control module (PCM).

The alternator field apparently was sending induced voltage into the connectors and therefore altering the MLPS signal to the PCM, which is probably why it acted differently at highway speeds from the way it did at slow speeds.

These late-model vans have the same wiring layout as long as they are equipped with a gasoline engine, which means it doesn’t necessarily have to have a 4.2-liter. The diesels are set up differently.

I ran into similar situations some time ago on GM trucks with 4L80 E transmissions. In cold regions of the country, it was common to change gasoline-powered vehicles over to propane, and the propane fuel system uses its own computer system. Inevitably, the wiring for this system would be too long. As a result, the technician installing the propane system would wrap the excess wiring around existing wiring, which always seemed to be the speed-sensor wires. Of course, this would interfere with transmission operation and cause erratic shifting and problems with the torque-converter-clutch signal.

These days more than ever, it seems that you have to be more meticulous about things that, in the past, would have seemed insignificant.

Once the wiring on this Ford van was secured properly, the MLPS signal returned to normal operation, as did the van.

Many thanks to Roly at Rainbow Transmission in Hialeah, FL, for sharing this with me.

Until next time.

Pete Luban is a technical consultant for the Automatic Transmission Service Group (ATSG) and a frequent contributor to Transmission Digest.