R&R Tech

- Author: Gary Calhoon

- Subject Matter: Diagnosis

- Unit: 4L80-E

- Vehicle Application: 3/4- & 1-ton GM trucks

- Issue: Engine stall on reverse engagement

We all know that the 4L80-E is a very common transmission, and in many applications that it is used in it sees moderate to heavy-duty usage. Because of its popularity, we see many of them in the shop. As with anything that comes into your shop on a regular basis, you can see certain failure patterns emerge that make for a good case-study. This article focuses on one such concern that grew into solving other issues as well: engine stalling upon reverse engagement, occurring immediately or shortly after installation of a remanufactured transmission.

We had seen six such instances of this in vehicles in the 2005-2008 model years. All the stalling concerns were attributed to plugged transmission-fluid coolers. The reason for the stalling is that fluid pressure is required to release the torque-converter clutch. Without fluid pressure (which is impeded by the plugged cooler), the clutch applies without command and kills the engine. Now that the cause of the stalling had been identified, we now needed to look at the larger picture: What was plugging the coolers?

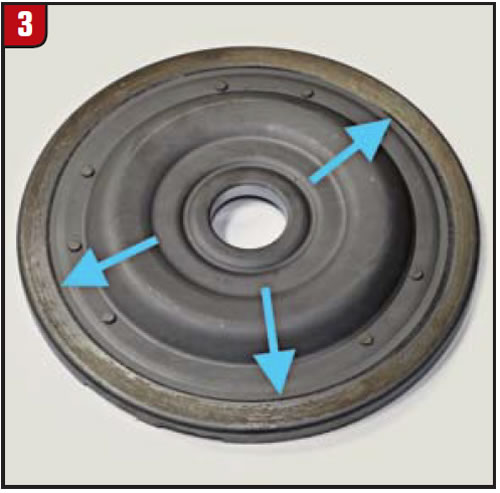

As we looked through the failure analysis on these units, it became clear that they all shared the root cause of failure of the torque-converter stator bearings (figures 1 & 2) and/or clutch linings. The debris created by these failures circulated throughout the cooling system, eventually collecting at the cooler and creating a blockage there. Stator-bearing failure is a relatively common event in 2000-up model years, as the bearing was insufficient for the application. GM has since released an upgraded bearing to replace the original design.

At this point, we have a better understanding of what creates these failures. However, because some of the failures we saw occurred immediately after our product was installed, we also had to look closely at how the units were installed. Our client base is very diverse and includes transmission specialty shops, general-repair shops and even do-it-yourself customers. Proper installation equipment and expertise will vary greatly from customer to customer.

Considering that the original transmission that was being replaced may have failed for the reasons cited previously, it’s easy to understand why our freshly installed product may not have functioned correctly out of the box. Those of us who have been in the transmission industry know that a clean cooler is paramount to a good installation of a replacement transmission. For today’s vehicles, any shop that is installing transmissions should own, or have access to, a hot-flush machine. It’s the only way to thoroughly clean a transmission cooling system. Of the six failures cited in this article, only one of the systems had been hot-flushed during installation of the remanufactured unit.

We also noted a high incidence of shredded torque-converter clutches. As you could guess, this clutch material will rapidly restrict or block a transmission-fluid cooler. When this occurs at speed, the additional cooler-circuit pressure can cause the torque converter to “balloon,” creating other problems. Stall speeds increase when ballooning occurs, creating more heat and a greater potential for complete transmission meltdown. In some applications, especially in motor homes, engine thrust-bearing damage can occur. In all instances, the torque converter will be destroyed.

One other interesting fact about these six cases is that they were all 3/4- or 1-ton vehicles. All were used as commercial vehicles, and all were used for heavy-duty hauling or towing. These types of vehicles require extra cooling capacity for the transmission, or else temperatures will reach a point where damage, and ultimately failure, will occur.

Adding an auxiliary cooler of the correct size can add years of life to a transmission that is being used hard. In one of our subject cases, we found that the auxiliary cooler added by the vehicle owner was too small for the application. Adding a larger-sized cooler reduced fluid temperature by 20°F, adding a very safe cushion for the transmission to operate within proper temperature ranges.

In general, regardless of the vehicle type or transmission, it is always a good idea to look at the transmission cooling system anytime you get a transmission concern, or service, in your shop. An auxiliary cooler or repair of an existing system is an easy sale, considering the consequences of not doing so. Cooling-system inadequacies have been the root cause of many transmission failures. Save your shop – and your customer – the headache and expense of an avoidable comeback.

Gary Calhoon, a warranty technical adviser, has worked for Certified Transmission since 2010 and has been in the automatic-transmission industry for more than 27 years. He began his automotive career in 1977 at a shop in St. Joseph, Mo.