Shift Pointers

- Subject: TCC cycling or surge

- Unit: Allison 1000/2000

- Vehicle Application: GM medium-duty trucks

- Essential Reading: Rebuilder, Diagnostician

- Author: Wayne Colonna, ATSG, Transmission Digest Technical Editor

In ATSG’s “Shifting Great in 2008” technical-training seminar we covered a complaint of TCC shuttle or surge with GM’s medium-duty trucks using Allison 1000/2000-series transmissions. This complaint usually occurs after converter replacement.

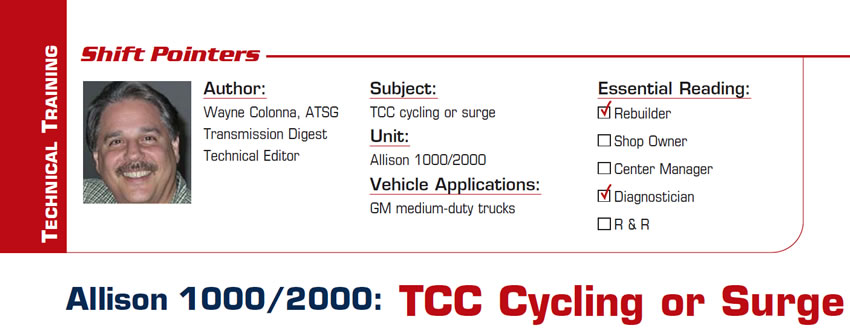

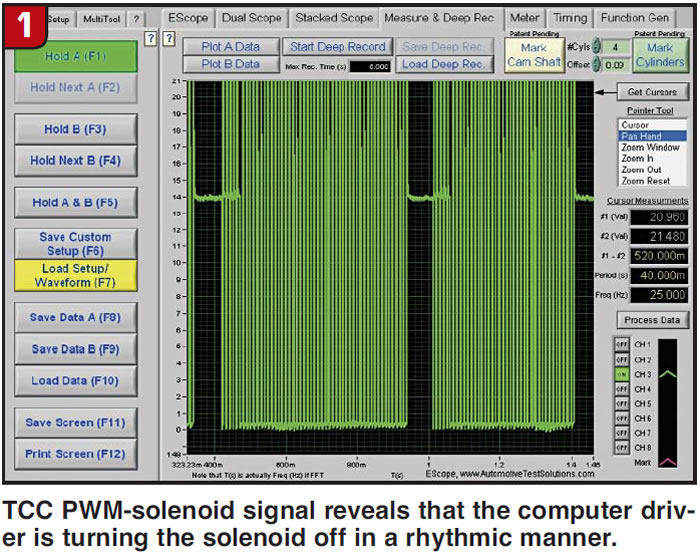

When the transmission reaches operating temperature, the converter clutch can apply as early as second gear, at which time the shuttle begins. But the way in which it shuttles, it could be misinterpreted as an engine miss. With a scope or a capable scan tool, it can be quickly determined that the computer is providing the cycling command of the clutch (figures 1 and 2).

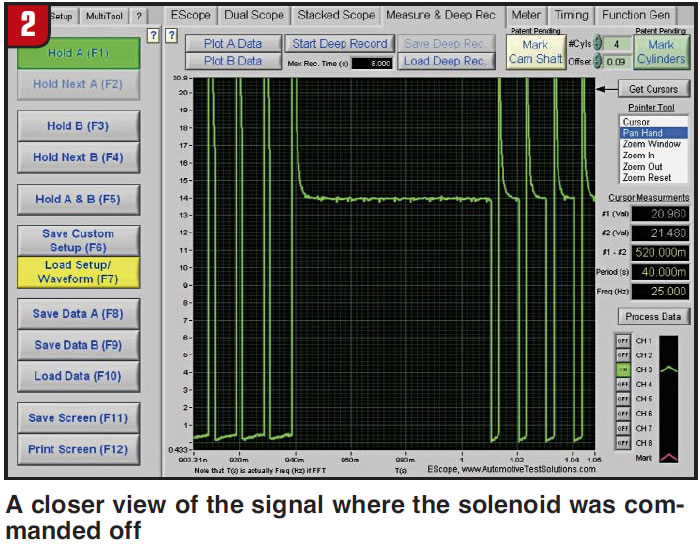

With the computer commanding the TCC to cycle off and on, not only does the question arise as to why but it also takes your thinking away from the work performed on the transmission. After all, it must be an electrical problem. Yet the problem was not there before the work was performed, and to make matters more difficult, no codes are present to give you a running start (Figure 3).

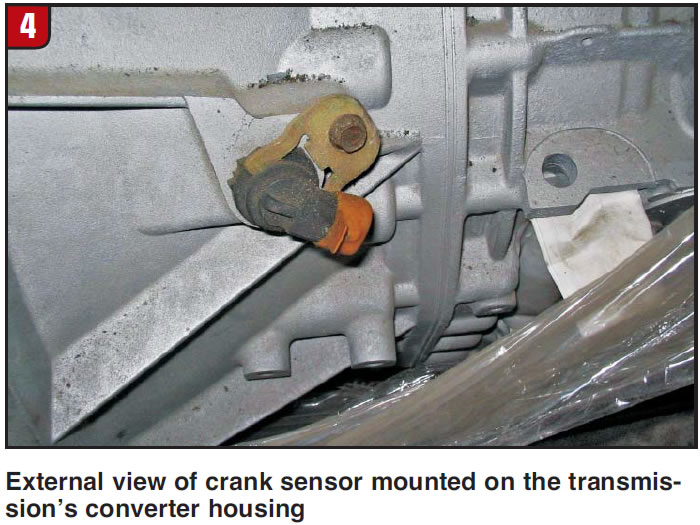

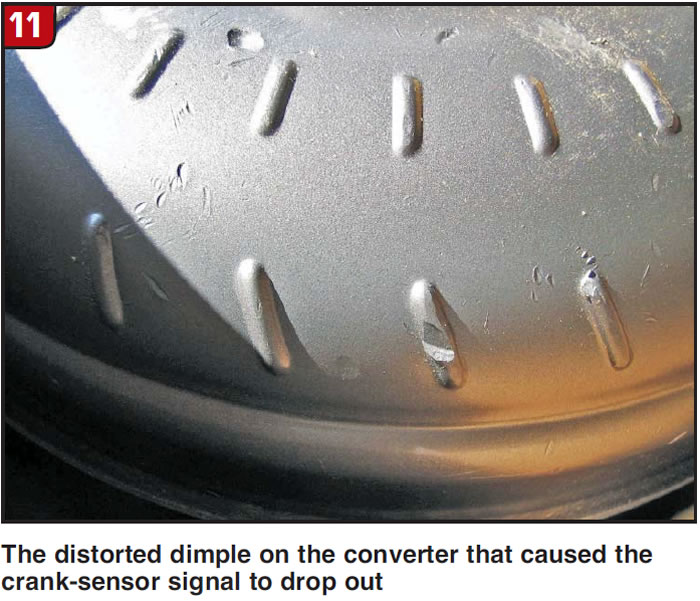

A fairly good look at engine and transmission data does not seem to reveal any good reason for this complaint. But the cause for this complaint is amazing. Without knowing what to look for you could be working on this problem for weeks. Such is what happened to the good folks at Lawrence Transmissions in Toronto, Ontario. After much time and effort they did resolve the problem. The reason for this complaint is that the crank sensor gets its signal from dimples that are on the converter (figures 4-6). If one or more of these dimples become distorted, there is a drop-out in the crank signal that in turn causes the TCC to cycle off and on.

One point that needs to be made is that you may run into some wiring diagrams that refer to this crank sensor (engine-speed signal) as an input-speed sensor. This, of course, could be misleading. In this article I will be referring to it as a crank sensor, as that is what it truly is.

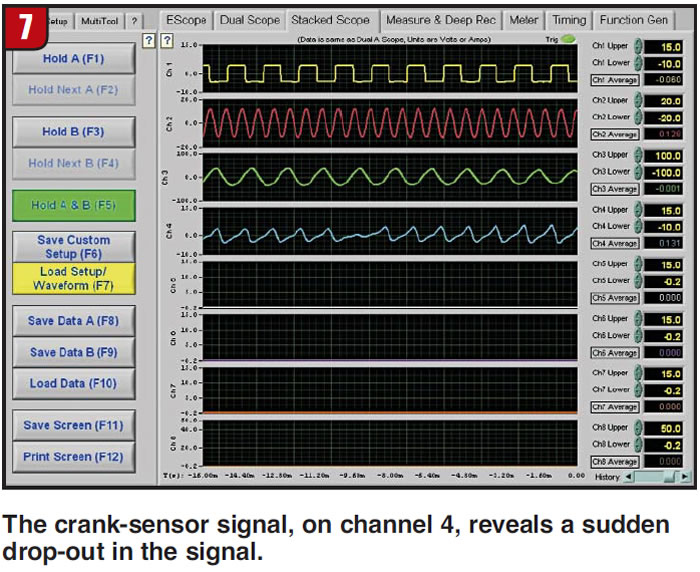

Bernie Thompson, the driving force and owner of Automotive Test Solutions, recently was called upon by a local shop that had this problem. The shop had spent days and countless hours trying to correct this condition. To Bernie’s credit, it took him a couple of hours to discover the problem, and during the process he documented what the crank-sensor signal looks like when this problem occurs.

Figure 7 is a screen capture that Bernie took with the eight-channel scope he developed for ATS, showing the crank signal on channel 4. You can easily see that there is a drop-out in the signal.

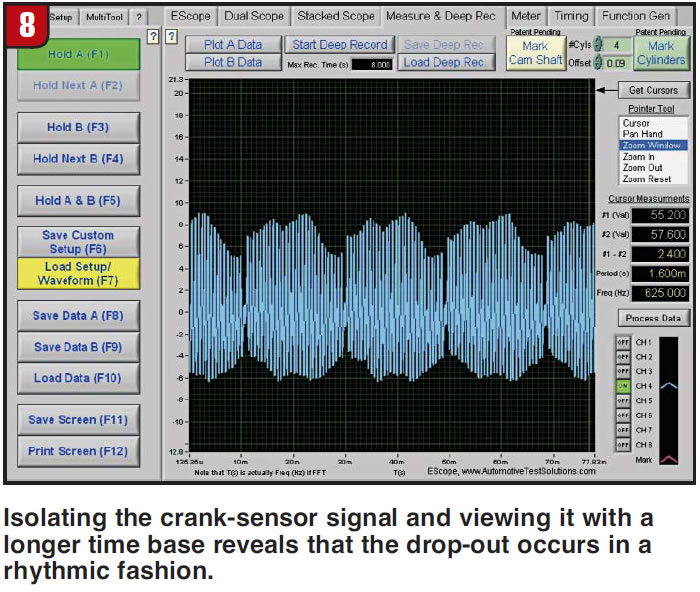

Bernie then isolated the signal and viewed it with a longer time base, as you can see in Figure 8. Viewing the signal in this fashion reveals that the drop-out occurred in a rhythmic fashion.

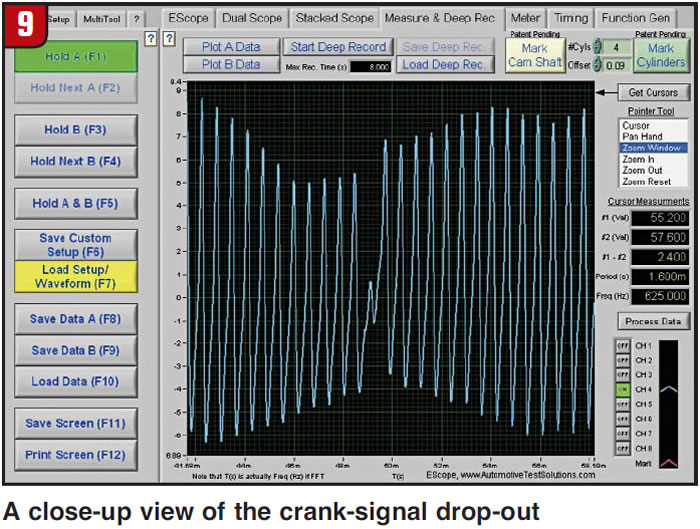

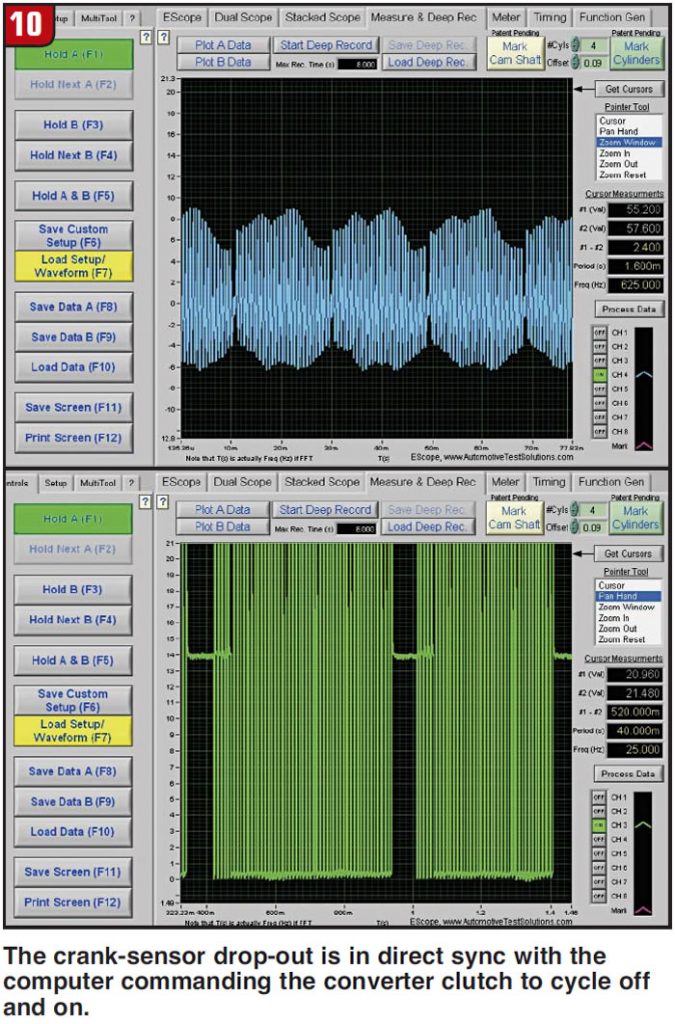

Figure 9 is a close-up view of this drop-out. By comparing Figure 1 with Figure 8, as we have done in Figure 10, you can see that the crank-sensor drop-out is in direct sync with the computer commanding the converter clutch to cycle off and on. And what caused this drop-out to occur?

Figure 11 shows the distorted dimple on the converter that caused this heartache.

What is interesting is that there are 31 of these dimples on the converter, and if you look at Figure 8 carefully you can count 30 peaks, with the drop-out signal being the 31st peak. What makes this interesting is that with a scope, you also could determine how many of these dimples have been distorted. In a Transmission Digest article in April 2007 Ed Lee wrote about a similar problem created when the rebuilder added a drain plug between two of the dimples. This would show up as a 32nd pulse.

What a great lesson in not only realizing that a signal can be bad – yet not bad enough long enough to produce a code – but also in knowing how a particular signal is generated. At the start of this article I made the comment that this complaint usually occurs after converter replacement. Notice I said “usually.” What I mean by that is in some instances you may not replace the converter but if you mishandle the one you have, it doesn’t take much to distort these dimples. Be careful to not cause a self-inflicted injury such as this one. And it may be to your benefit to inspect your replacement converter before installing it.

Many thanks to Bernie Thompson for the screen captures that made this article possible. Besides his eight-channel scope I also use his four-channel scope. Either one is a great tool to add to your diagnostic arsenal.