TASC Force Tips

- Author: Tory Royce

- Subject Matter: Chrysler transmissions

- Issue: Solenoid switch valve

Identification & Repair of Chrysler Solenoid Switch Valve Problems

You may have noticed some similarities over the years in regard to a family of Chrysler transmissions that began with the Ultradrive 4-speed automatic in 1989. In its day it was fairly innovative, featuring clutch-to-clutch operation (no bands) and adaptive shift technology. Over time, the basic structure has developed into a variety of different models, some with 5- and 6-speed variations.

Because of the family lineage, many builders also may have recognized a commonality among this group of valve bodies. For identification purposes, let’s break down the family tree into two distinct branches:

- Branch #1 is the 41TE group, which consists of the 40TE, 40TES, 41AE, 41TE, 41TES, 42LE and 42RLE.

- Branch #2 is the 45RFE group, which began in 1999 and includes the 45RFE, 545RFE, 62TE and 68RFE.

While the 41TE side of the family (Branch #1) uses a rectangular type casting (Figure 1), their 45RFE relatives (Branch #2) use essentially the same components in an L-shaped valve-body design (Figure 2). The beauty of these similarities is that many symptoms can be traced to the same wear areas in the castings, perhaps the most common of which is the solenoid switch valve bore.

Because there are no bands, precise fluid control is critical for proper clutch application. In this system, control duties are handled by three primary elements: the solenoid pack, pressure switches and — the subject of this article — the solenoid switch valve. The main function of the switch valve is to direct fluid between the L/R clutch and TCC, but it also directs oil to the 2nd and OD clutches by means of two shuttle valves or “plugs” in the end of the bore. As wear develops in the bore, it is common for the switch valve and plugs to stick, which causes a variety of different symptoms. Among these are:

- Bind up

- Codes 841, 868, 871, 988, 1775, 1776

- Engine stall

- Failsafe mode

- No lockup

- TCC apply and release concerns

- TCC codes

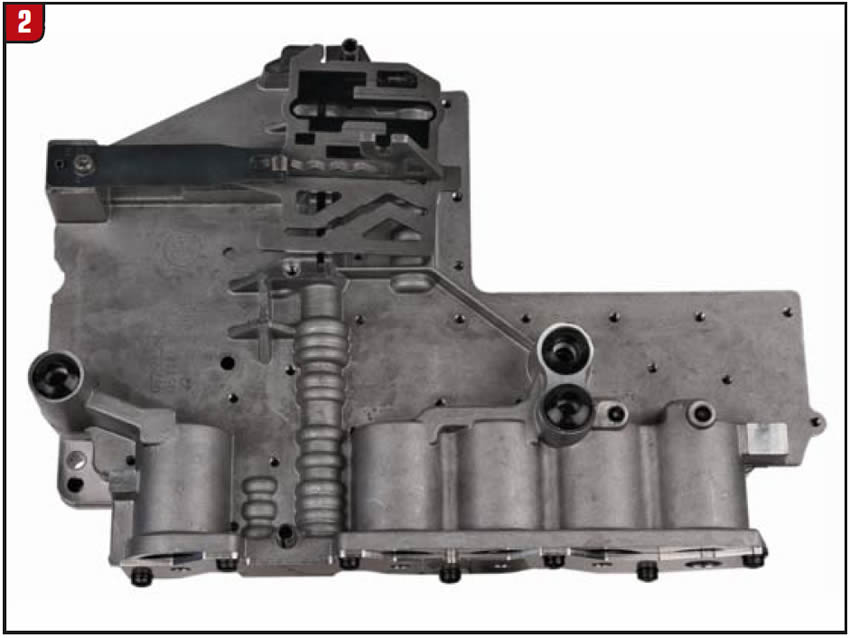

As shown in Figure 3, all units originally used a 0.420″ diameter switch valve design with 0.453″ diameter plugs. In the 41TE group (Branch #1) around the 2006 model year, Chrysler introduced a new switch valve design that increased the diameter of the largest spool to 0.453″. Because of this change and differences in linear spacing of the spools, the three outer plugs (including the end plug) remained the same diameter, but the center plug grew in width from about 0.340″ to 0.388″. This change did not take effect in the 45RFE group (Branch #2) until around the 2010 model year.

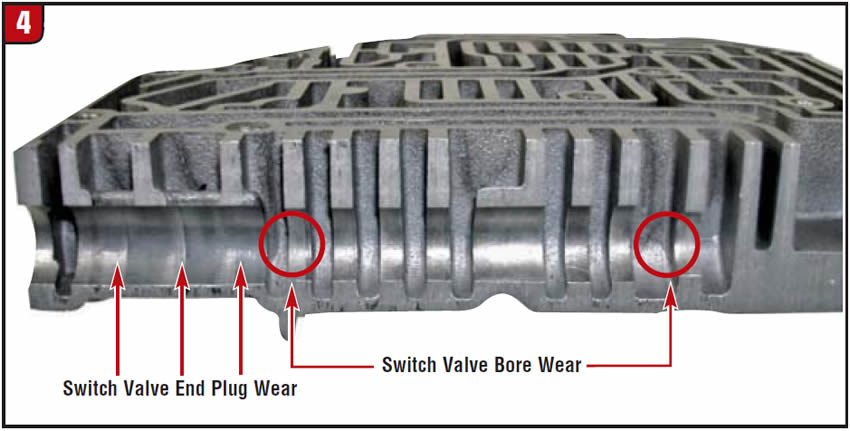

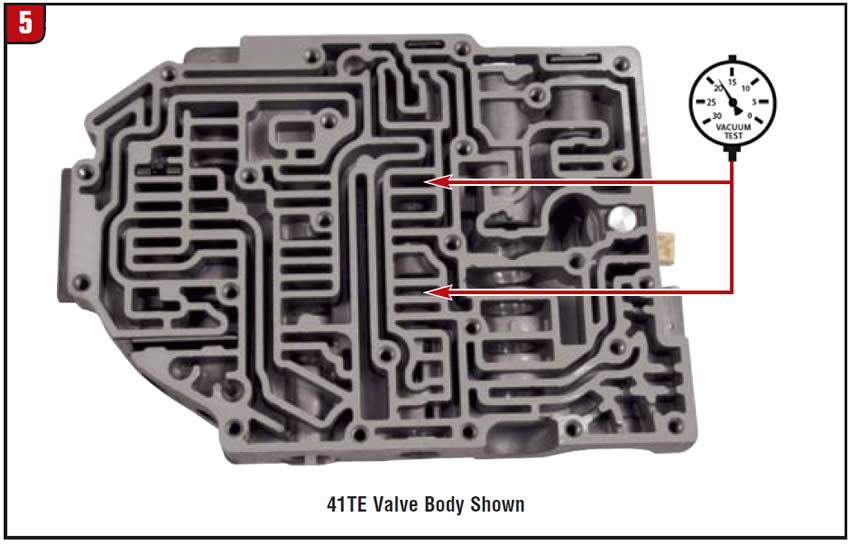

While in many cases the wear is obvious (Figure 4), vacuum testing is going to be your best bet in determining when a repair is in order (Figure 5).

The good news is that aftermarket solutions are available to correct the bore and its components; just make sure to measure the switch valve prior to making any repairs. The tooling required to perform this repair depends on properly identifying the large spool diameter of the switch valve. Using the wrong tooling setup can result in wasted time and irreparable damage to the valve body casting.

It’s common to see a few outlaw members in the family tree that need help finding the path of righteousness. In this case, however, the problem is easily recognizable, and restoring order to the family is a fairly simple solution. Don’t you wish every family problem could be corrected that way?

Tory Royce is a Sonnax technical support specialist and a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians.