Shift Pointers

- Subject: Avoiding injury from onboard fire-suppression system

- Unit: Ford police cars

- Essential Reading: Shop Owner, Center Manager, Rebuilder, Diagnostician, R & R

- Author: Pete Luban, ATSG Transmission Digest Contributing Editor

As new vehicles roll off the assembly line, they contain more doodads than the previous model. Some of these doodads are standard equipment and some are optional equipment.

The doodad we’re going to discuss here is an optional one that is installed by Ford Fleet Services, a subsidiary of Ford Motor Co. Ford Fleet installs systems in fleet vehicles such as police cars that include items like the flashing roof lights, sirens, Kevlar‚ lined trunks etc. Ford Fleet also installs a fire-suppression system, which is the one we’re going to discuss here.

The fire-suppression system is designed to deploy in the event of a high-speed rear-end collision with a resulting fuel-tank fire to give the occupant(s) of the vehicle adequate escape time, thereby preventing serious injury.

The fire-suppression system consists of two stainless-steel containers that hold the fire-suppressant liquid and gas generators that pressurize and deploy the liquid suppressant material. The system also contains two manifold assemblies, each with deployable nozzles that spray the suppressant liquid toward the fuel tank.

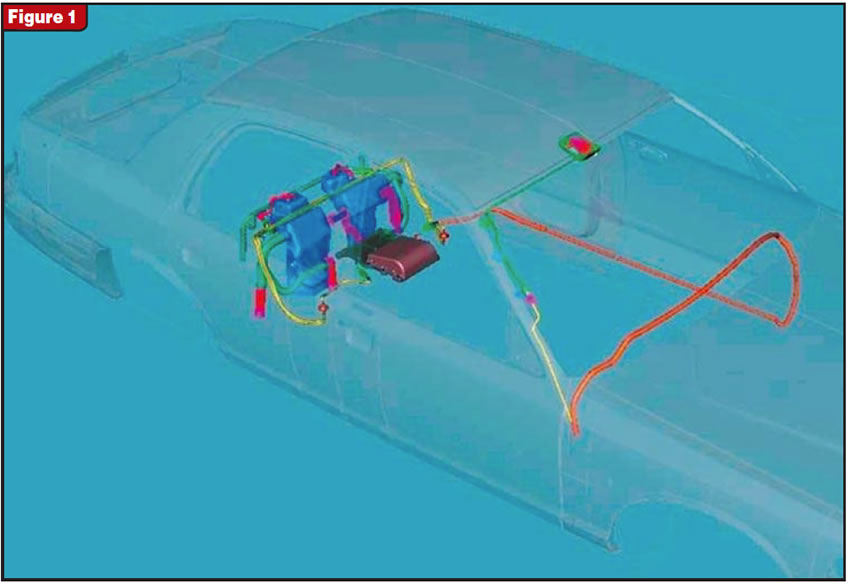

Figure 1 shows the general layout of the system, which is mounted over the vehicle’s fuel tank. Two additional high-pressure nozzles are directed upward toward the body.

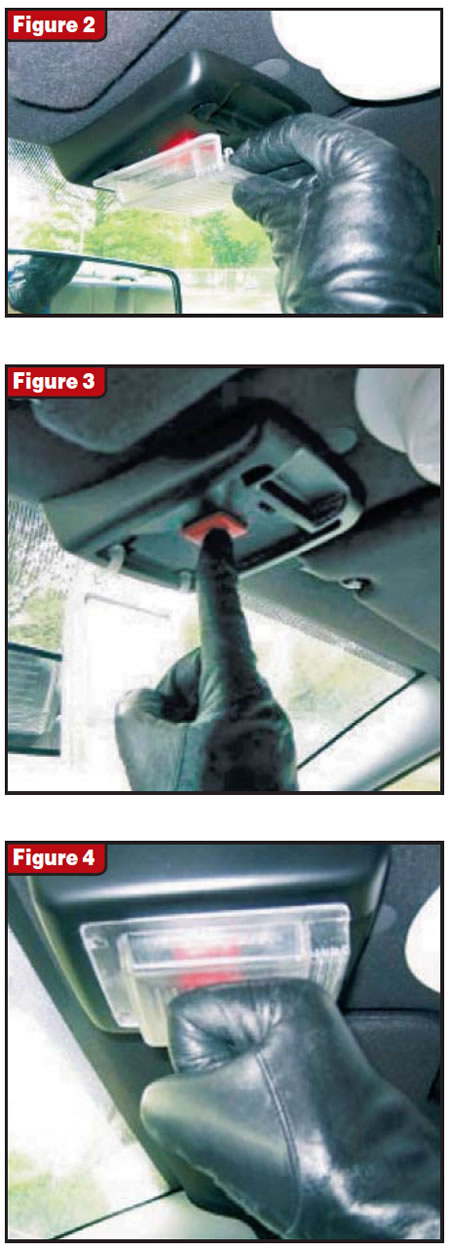

The system also is equipped with an electronic control module, under the rear seat; a rear-crash sensor; a large electrical capacitor for backup power in case the vehicle loses its power; two redundant wiring harnesses that are armored to protect the harness during a collision; and a manual activation switch by which the system can be deployed either by swinging the hinged plastic cover and then pushing the red button (see figures 2 and 3) or delivering a blow to the plastic switch cover (see Figure 4).

The system will delay deployment until the ABS wheel-speed sensors indicate the wheels have slowed and the vehicle is coming to a stop. Should the input signals from the wheel-speed sensors fail as a result of the collision, a backup timer will deploy the system six seconds after impact.

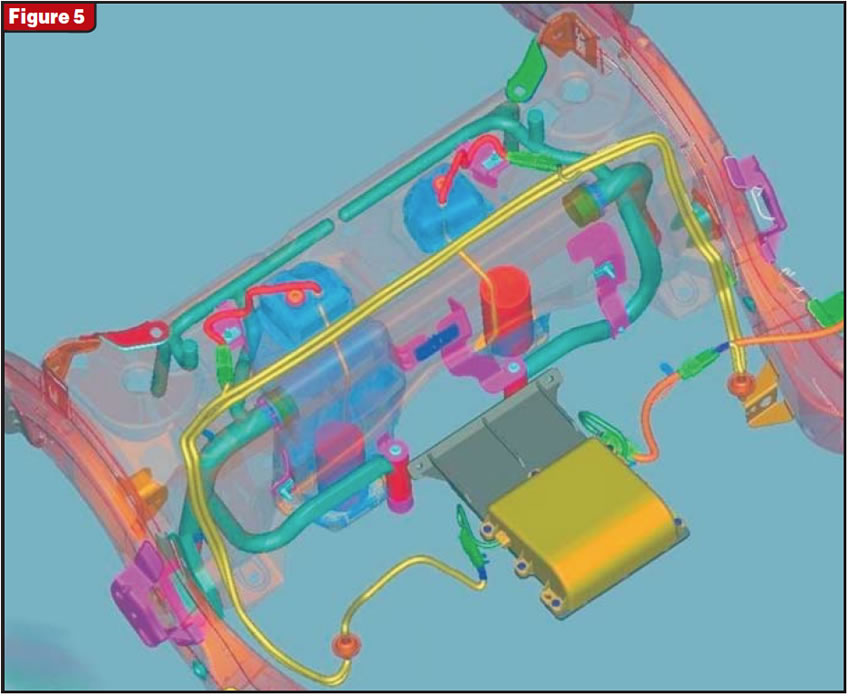

This fire-suppression system cannot be retrofitted into earlier vehicles because it is integrated with the vehicle’s computer system, which is new for 2006, and the vehicle’s frame was modified to support the additional weight of the system at its mounting points over the fuel tank (see Figure 5).

So what does all this mean to you? It means that you may come in contact with one of these vehicles that are equipped with this system because you may do dealer warranty work or perhaps have a fleet contract for city vehicles.

There are a few things you will need to know to avoid personal injury in the event of an “accidental deployment” of the system.

The fire-suppressant material is mostly harmless, although it could cause some minor skin or eye irritation. However, it is the force with which this material is deployed that can put you in the hospital.

The one thing that Ford Motor Co. and Ford Fleet Services agree on is that if any of the fire-suppression components are to be touched or any components around the system, including rear-axle components, require service, the fire-suppression system must be powered down before you even raise the car on a lift.

To deplete the backup power supply, disconnect the battery cables and wait at least one minute. Don’t forget any auxiliary batteries that the vehicle may be equipped with.

It’s a good idea to wear safety glasses when working in the vicinity of the fire-suppression system. Since this system’s power must remain depleted until repairs have been completed, do not use any type of memory-saver device! Never back-probe any of the connectors that are part of this system.

Even after repairs are completed, it is possible to have an accidental deployment of this system when the battery cables are reconnected.

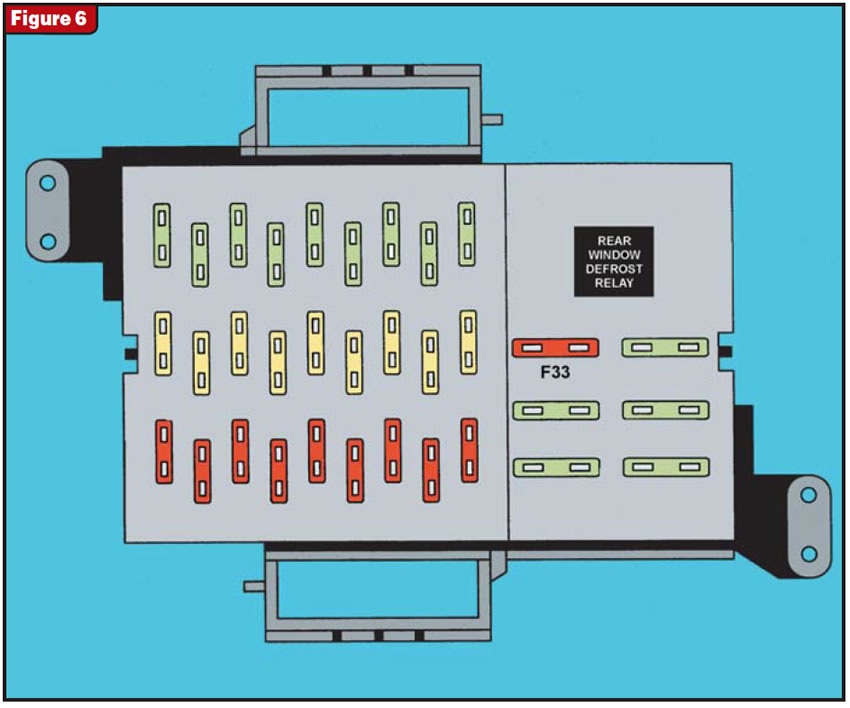

To avoid this, remove the F33 fuse from the central junction fuse box (refer to Figure 6) under the driver’s side of the dashboard before reconnecting the battery cables, as the sudden surge of restored power could deploy the system. The fire-suppression indicator lamp will be on steadily when the F33 fuse is removed and the ignition is on; this is normal operation.

Once the fuse is reinstalled, the fire-suppression lamp should go out in about six seconds if all is well. If all is not well, the lamp will flash about 30 seconds after a key cycle, indicating a system fault, at which time the scan tool comes out for code retrieval and clearing.

It’s better to know about the existence of something like this than to be taken by surprise with the possibility of personal injury, so be careful out there.