R&R Tech

- Author: Chris Adams

- Subject Matter: Automatic transmission

- Vehicle Application: 2005 Chevrolet Avalanche

- Issue: Sticking in 3rd gear

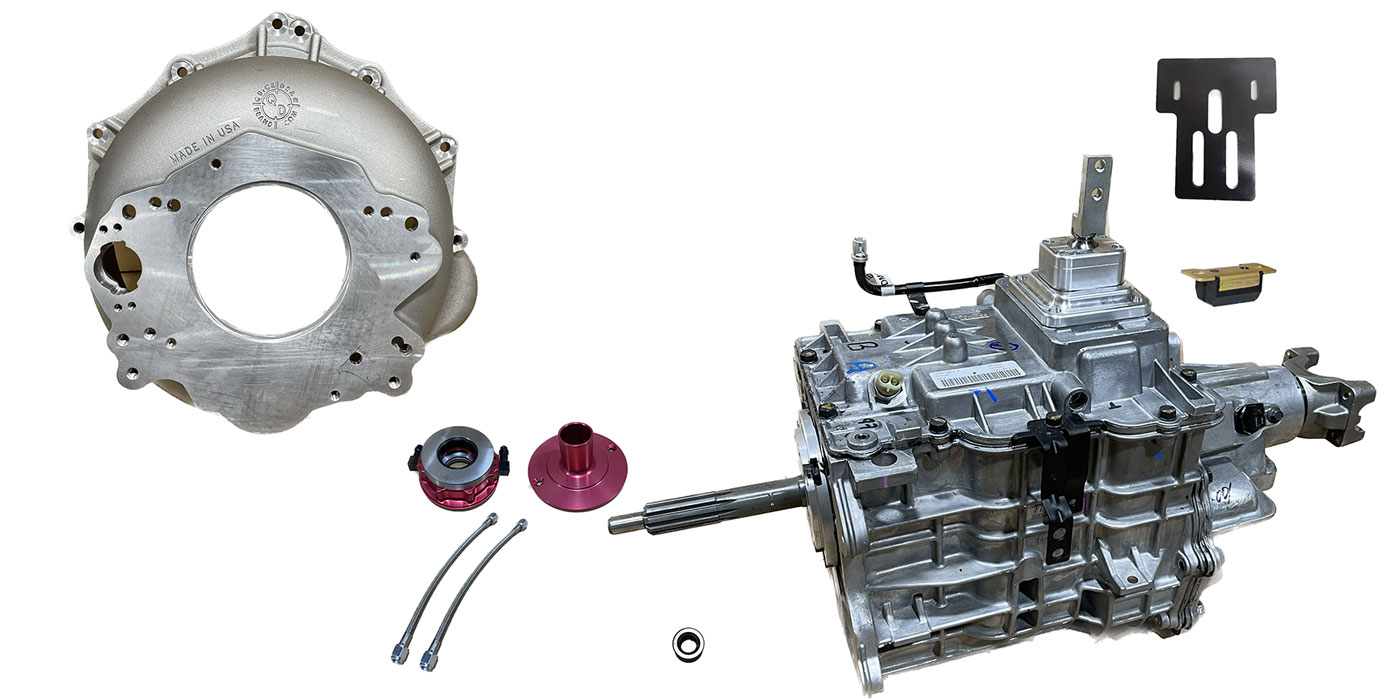

Recently a 2005 Chevrolet Avalanche came into one of our shops with the customer concern of the transmission sticking in one gear intermittently, and the Service Engine warning light illuminating. When I went to start our pre-diagnostic evaluation I grabbed the scan tool and went out to the vehicle, only to notice that it had a “Smart Start” ignition interlock device installed (Figure 1).

At this point I decided to hook up the scan tool and check for codes before driving the vehicle, and I pulled codes P0740, P0753, P0758, P0785 and P2761. On the basis of these codes, we advised the customer that he had an electrical issue and we would need some additional diagnostic time. The customer agreed and left the vehicle with us to diagnose.

When we encounter these devices on customer vehicles, our standard procedure is to disable the interlock device. Armed with instructions from the interlock manufacturer, we bypassed the interlock and proceeded with the diagnostic process.

In my experience (and likely yours also), the ignition switches in GM trucks have had frequent issues for years. With that experience in mind, I hooked up my Fluke digital multimeter (DMM) to the Ign 0 fuse and monitored the voltage. Typically, the voltage drop occurs after the start command. After multiple attempts I could not see the voltage drop. I then set up the DMM to record the events. I started the truck and left it idling for about 20 minutes. When I returned to check the meter, I discovered a low reading of 6.2 volts on the recorded data. Since these ignition switches have been problematic, my recommendation was to replace it with an OEM ACDelco part. The customer authorized the repair, so we replaced the part, cleared codes and rechecked the operation of the unit. Everything was now working normally. From that point, we removed the bypass from the interlock and then released the vehicle to the customer.

Unfortunately, the customer called the next day and said, “It’s doing the same thing again!” Those are six words you never want to hear. Early the next morning, the customer dropped the vehicle off with us again. This time I decided to leave the interlock intact and proceed with the diagnosis again. A scan showed that the same codes as found previously had returned, so I hooked up the DMM to the fuse again to try to see a voltage drop in the circuit. After multiple attempts I could not find an issue, and the vehicle did not set the codes again.

I then moved the DMM lead, back-probing right at the transmission connector, with no issue found there. I decided to road-test the vehicle some more, thinking that we might have had an intermittent connection somewhere and a road test might replicate the issue. Now remember, this vehicle has an interlock installed that the driver must blow into before starting the vehicle, again after five minutes of driving and then every 15 minutes after that. This made the road test a bit different from the norm.

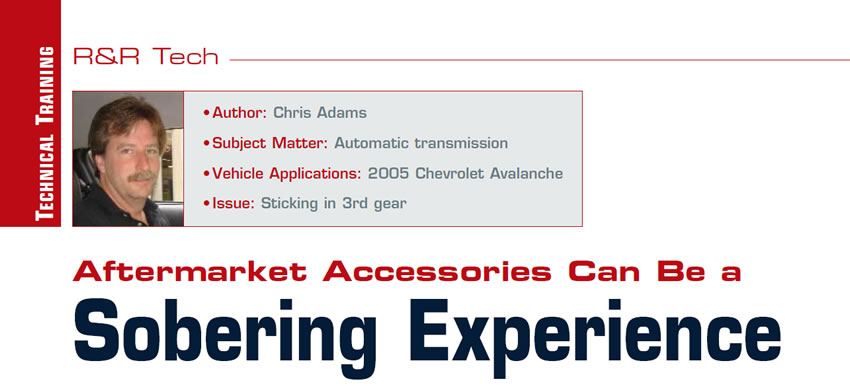

At this point I had about two hours into trying to duplicate the problem but was unable to get the vehicle to act up. As I was sitting there in the driver’s seat wondering what I was missing, one of those “aha” moments occurred. I reached up and turned the ignition switch to Start and the vehicle started, which would normally be expected, but in this instance I hadn’t blown into the interlock device. The vehicle should not have started. I also noticed that there was no power at the transmission, per the DMM (Figure 2).

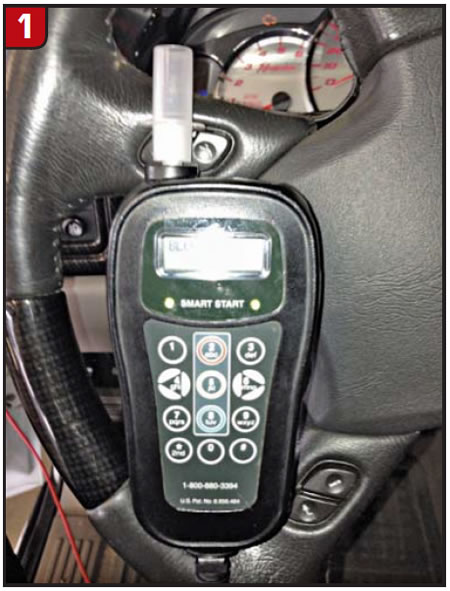

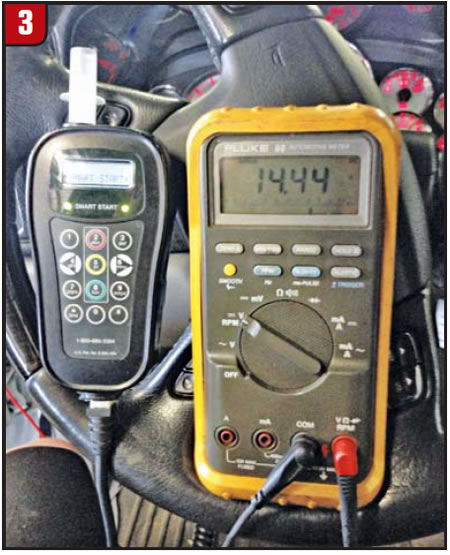

I then blew into the device, and when it passed I had power at the transmission (Figure 3).

I turned the vehicle off, tried it again and repeated the results. It came down to the fact that the interlock device was not installed properly, seemingly not tied into the correct circuit. Interesting enough, if the device had been used the way it was designed, the transmission problem never would have surfaced. What I believe was happening is that with the very large speakers in the back, the customer was unable to hear the device beeping when it requested the breathalyzer test at the predetermined intervals.

Instead of disabling the vehicle as designed, it simply killed power to the fuse that supplied power to the transmission, causing the unit to lock in third gear and setting all the transmission codes. Although this is not a common problem, I do believe that this situation could be translated into other aftermarket devices such as remote starts or vehicle security systems.

Since we are not an authorized installer of this device, we could not repair the problem ourselves so it needed to be returned to the installer for repair. The customer called a few days later and told us everything was working well after the installer had corrected the breathalyzer installation. Sounds like a great cause for a sober celebration.

Chris Adams is the lead diagnostician for Certified Transmission in the Omaha, Neb., area. He has been with the company for more than 25 years.