Up to Standards

- Subject: Diagnostic principles for transfer cases

- Units: NVG 247, 249

- Essential Reading: Rebuilder, Diagnostician

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

As automotive technology and design have reached new levels of sophistication, the role of the diagnostician has risen to critical levels. It is possible to replace transmissions and transfer cases with factory or aftermarket new or remanufactured units with relative ease. The shop needs only a qualified installer to make the swap.

Who decides, though, whether the transmission or transfer case actually needs replacement or the problem is in the electronics – or some other area outside the unit? The decision depends on the person doing the diagnostics. To successfully diagnose problems, the person involved has to have a thorough knowledge of how the driveline works and all the systems that are related to it.

We are going to take a look at some problems that come over our tech lines and have confused and frustrated a number of talented technicians. To do that we need to go over some basic diagnostic principles that formulate steps for diagnostic success. If you skip these steps you will be lost.

Anytime you are looking at a vehicle with a transfer-case complaint, start at the tires. Are all the tires the same size and correctly pressurized? This does not mean looking at sidewall labels; measure the tires physically. The smart way to do this is with a “stagger gauge” (Figure 1), which is nothing more than a large caliper that reads tire circumference directly. You can measure all four tires in less than five minutes. If all the tires are not within 0.250 inch in diameter do nothing until they are matched correctly. Every week we speak with technicians who refuse to believe the importance of that statement, and they waste a lot of time and money. You would not try to diagnose a computer control problem without first checking battery voltage, so why is tire size such a mystery to grasp? Mismatched tire sizes damage differentials, fry viscous couplings, burn up clutch packs and cause all kinds of crow hop and other handling complaints in all-wheel- and four-wheel-drive vehicles.

The next step is to check the front and rear differentials to make sure they are the same ratios, the side and spider gears are functional and there are no stripped or broken axles. A simple test with the vehicle off the ground is to have someone hold one wheel still as you try to turn the other wheel. On vehicles with front-axle disconnects it will be necessary to have the vehicle running with the axle engaged. If you can turn the wheel while the opposite wheel is held stationary, there is an axle or side-gear problem in the differential.

Another quick test is to place the transfer case in 4W Low range and drive the vehicle if possible. This locks the front and rear axles together. Making a tight turn in 4W Low range will cause the truck to bind up and crow-hop, which is how it is supposed to work. This means that we now know the axles and differential gears are responding properly. If the unit does not bind up in turns in low range, there’s a problem with the axles or differential gears, or an internal transfer-case problem.

Transfer cases in late-model vehicles have reached a high level of sophistication and are no longer simple mechanical power dividers. The intelligent or electronically controlled transfer cases use internal clutch packs to seamlessly apply 4WD in the automatic modes without driver intervention. Viscous couplings and hydraulic pump couplers do the same thing mechanically. Understanding how these units work is the first step in the diagnostic process.

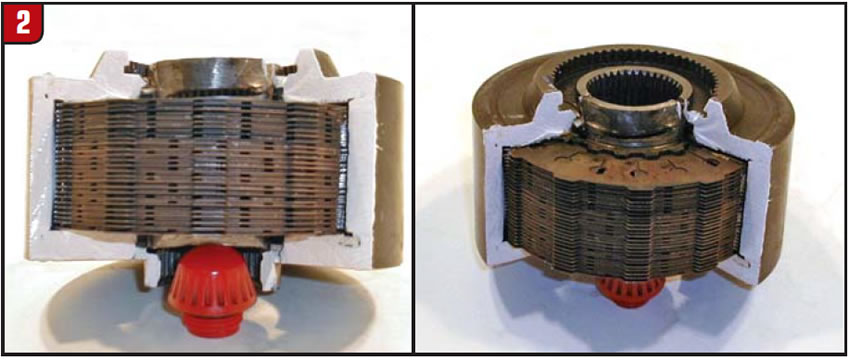

The viscous coupling (Figure 2) is a sealed unit containing alternately splined discs that, unlike in a clutch pack, never contact each other. The case is filled with a special silicone fluid that expands greatly to fill the case when there is a difference in speed between the front and rear axles. As this fluid expands the internal plates are bound together by the shear effect of the fluid and transmit power to the wheels needing it. Once the wheel speeds have equalized the viscous coupling cools and the fluid shrinks back to its normal size and relaxes the plates, going back to 2WD.

Replacing a viscous coupling is an expensive deal, and if the tire sizes are not matched or there is a problem with differential gears or axles, it will fail quickly by overheating and locking up.

This will make the vehicle bind up on turns as if in 4WD Low range.

A hydraulic-pump coupler is similar in operation. Found in the NVG 247 transfer case and some Dana Jeep differentials, it is a clutch-operated system. The output shaft in the transfer case drives two pumps, one supplying pressurized lube to the unit and one that pressurizes the clutch pack in the coupler. If the front and rear output-shaft speeds vary, the pump pressure is increased, locking up the clutches and transmitting power to the front axle. Again, when shaft speeds equalize, the pump releases the pressure and the vehicle is back in 2WD. There is no driver control over these events, and mismatched tires, low or overheated lube, or damaged or missing axle components will quickly fail one of these units.

Now that we understand the basics of these operations we can begin to diagnose them more quickly with better results. In the following examples a mixture of greed, poverty and the fact that the economy is in a crash-and-burn state all conspire to cause problems that will drive you mad.

The 1996-98 Jeep Grand Cherokee is equipped with a 249 transfer case, which is a viscous-coupling unit – expensive to fix when the viscous seizes up. The customer now asks a shop to just fix it so it doesn’t bind up on turns, so he can trade it in. That shop removes the spider gears from the front differential, and there is no more bind-up and also no more 4WD. This customer now trades or sells the car to a dealer or individual who may not be sharp enough to realize that the transfer case is not working properly. It is sold to a new buyer, who now brings it to your shop for repairs. If you are not in touch with the basics of this diagnosis, this will be a bad week for you.

1999-and-up Jeep Grand Cherokees are equipped with the NVG 247 transfer case, which uses the pump coupler and, if equipped with Quadradrive, Dana Hydralock differentials that use a hydraulically applied clutch system to lock up the differentials. The V-6 models use a Dana super 35 differential, and the V-8 versions use a Dana super 45 differential. Both the transfer case and differentials are quite expensive to fix if the pump couplers have failed. Same scenario: The customer asks the shop to just patch it up so he can trade it in. On the differential the axle engages the side gear and the pump drive gear, so the shop shortens the axle so that it engages only the side gear and not the pump coupler, which removes the bind condition but eliminates four-wheel-drive. The new owner brings it to you for repairs, and you get more gray hair if you don’t know what to look for.

Toyota Land Cruisers are expensive vehicles, which means that repairs and parts are also expensive. These units are equipped with closed-knuckle front axles, an older axle design that has a ball-type end for steering with an enclosed axle shaft that is not visible. The transfer case is a viscous-coupling type. When the customer realizes the cost of the repair, the patch is to remove the front axle shaft, which is inside the housing and not visible from the outside. Again, problem solved for the binding condition, but no 4WD. If you get one of these and miss the diagnosis, the job will be a loser. We have seen the same problems with Mitsubishi vehicles with independent-front-suspension axles, where a party or parties unknown have removed the spider gears in the front differentials to get rid of the problem vehicle.

In the past year we have spoken with technicians across the country who have faced these complicated problems. More than 20 such incidents have come across the tech hotline. You can’t make this stuff up; it exists and will continue to plague our industry in the future.

The only defense you have is to be prepared for the unexpected by being sharp with your diagnostic skills and understanding the theory of operations for the vehicles you work on. Think outside the box and test all the parts of the four-wheel-drive system you are looking at. If all the parts that the system needs to function are not working, going inside the transfer case is useless. Always work from the outside in, with the removal of the unit the last operation instead of the first.