Shift Pointers

- Author: Pete Luban

Grinding or Bind-Up in Reverse

As best I can tell there are about 60 versions of the Honda/Acura four-speed transaxle to date. Some of these units, at a glance, look the same. Of course, as you know (usually found out the hard way), they are not the same. As a matter of fact, sometimes even when you look a bit closer they still look the same. This is mainly because of very subtle differences in the pieces and parts contained in these units.

A common area for these differences to trip you up is the reverse-selector assembly, which in this article pertains to the Acura two-shaft units covering the G4, L5 and PL5X in the Legend models 1987 to 1990.

When the driver makes a garage shift to Reverse, the transmission exhibits a grinding noise and/or a bind-up condition. This complaint occurs after one or more of the reverse-selector components on the countershaft have been replaced during rebuild.

Incompatible reverse-selector components on the countershaft have been installed. These components for the G4, L5 and PL5X look the same at first glance but will not interchange.

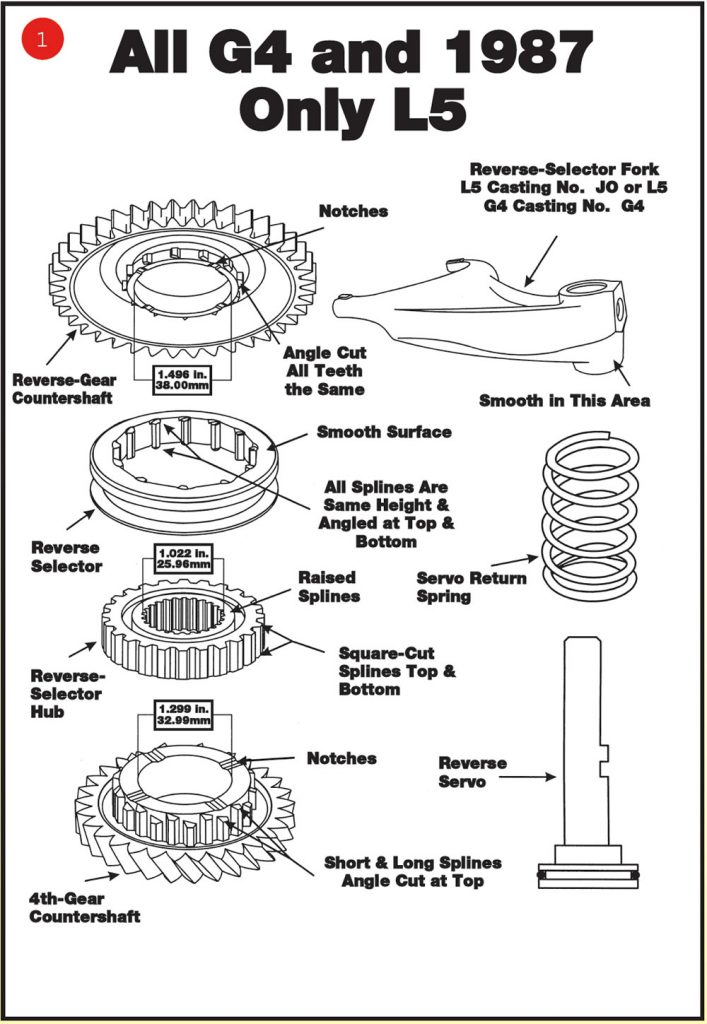

Figure 1 illustrates the differences in the G4 and 1987 L5 reverse-countershaft components. Note the diameters of the components and the tooth and spline configurations. The reverse servo uses a spring to return the piston to the 4th-gear position.

Note: The original-equipment G4 components were used in the 1987 Legend coupe only, with the L5 transaxle. Compare the illustrations in Figure 1 with Figures 2 and 3.

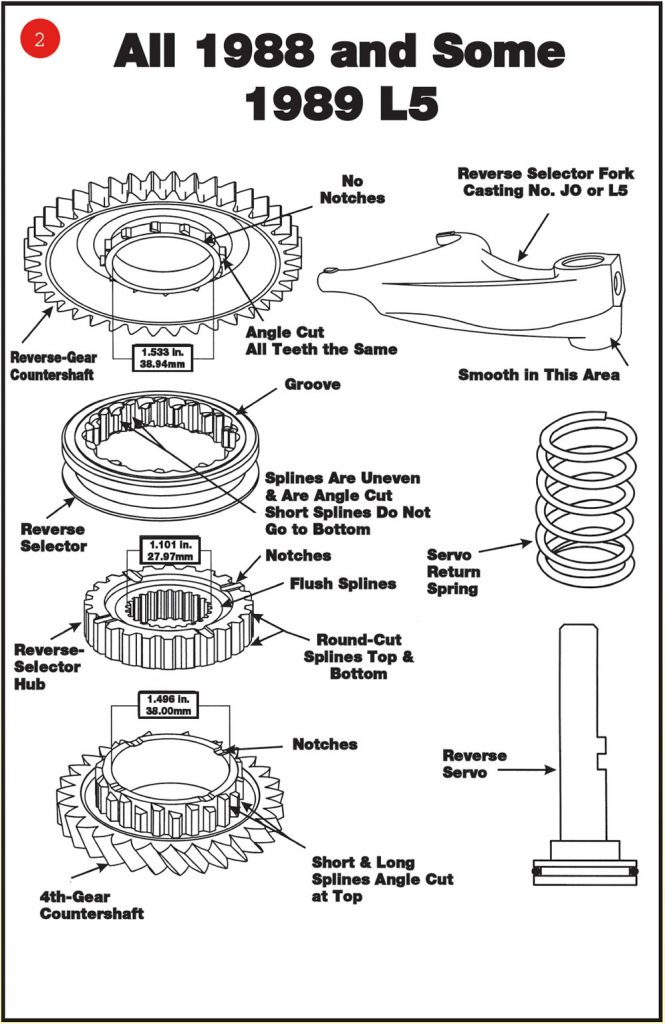

Figure 2 illustrates the differences in the 1988 L5 and some 1989 L5 reverse-countershaft components. Note the diameters of the components and the tooth and spline configurations.

This reverse servo also uses a spring to return the piston to the 4th gear position.

Compare the illustrations in Figure 2 with Figures 1 and 3.

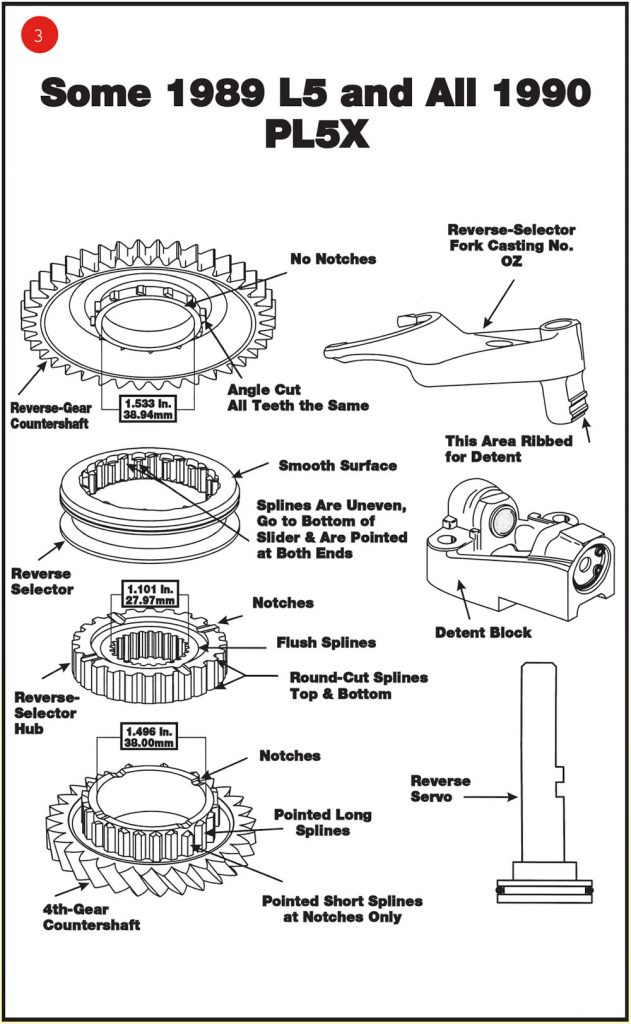

Figure 3 illustrates the differences in some 1989 L5 and 1990 PL5X reverse counter shaft components. Note the diameters of the components and the tooth and spline configurations. The 1989 L5 and 1990 PL5X do not use a servo return spring, as they have a detent mechanism to keep the reverse servo in the reverse or 4th-gear position. The fork also is different from the previous design level in that it is ribbed to accommodate the detent mechanism.

Compare the illustrations in Figure 3 with Figures 1 and 2.

Honda/Acura internal components look very similar. Always look closely to avoid this misassembly or any of the many other problems that incompatible parts can create.

Even though parts look the same, there can be slight dimensional differences. Because clearances in most Honda/Acura units are 0.003 in. to 0.006 in., there is little room for error.

Always check endplay before final assembly of the transmission.

Other areas where a mismatch can occur include the manual-valve detent mechanism, bearing thicknesses, and case and valve-body worm tracks, so take a little extra time and check those replacement parts carefully.

Special Note: These are correction pages for illustrations that mistakenly were published in the 2001 Seminar Blue Book and in the February 2001 issue of Transmission Digest.

Pete Luban is a technical consultant for the Automatic Transmission Service Group (ATSG) and a frequent contributor to Transmission Digest.