Tech to Tech

- Subject: Engine cuts out at 3,000 rpm

- Vehicle Application: Cadillac Catera

- Essential Reading: Diagnostician

- Author: Jeff Bach

Could the timing belt be the problem?

There seems to be a direct relationship between the state of the economy and the kind of jobs that find their way to my door. It never ceases to amaze me the lengths people will go to try to save money. Inevitably, one of the things they decide to cut is the cost of diagnosis.

We just finished a Cadillac Catera for a customer of another shop that took the car to still another shop that brought it to me to put on a timing belt. We were told that the first shop had replaced most of the parts because the technician found a Web site that addressed the problem this car was having. The different fixes, the Web site suggested, were to replace most of the parts – none of which seemed to fix his problem. I’m sorry if anyone gets offended out there, but it just seems that there is something inherently wrong with an auto shop that fixes cars by popular opinion on an Internet Web site. As I’ve heard Mark Warren say, “A monkey with a dart board would have a better chance at guessing right.”

The guy who dropped off this Catera made the statement, “The only thing that they said would cause this problem that we didn’t try was the timing belt.” He then assured me they would have put one on and were debating doing so, but according to the guys on the forum they were reading there were special tools needed to do the timing belt.

They figured we’d have the tools, being Cadillac specialists. I had to explain to the guy that I had my own way of arriving at diagnostic conclusions and much of my job included me getting to play with some of my equipment. I told him I wouldn’t mind doing the timing belt – after I get paid to play with my toys – if I concluded that it did indeed need a timing belt.

He was OK with that and agreed for us to “proceed.”

My wife, Angel, and I test-drove the car, and sure enough it ran fine except for cutting out at 3,000 rpm like a rev limiter. The car came with a laundry list of parts that had been replaced, including – but not limited to – spark plugs, coil packs (both sides), the electronic control module (ECM), fuel filter, fuel pump, fuel-pump relay, cam sensor, mass-air-flow (MAF) sensor and the throttle-position sensor (TPS).

“Could it be the ground?” Angel asks facetiously.

“It’s possible,” I reply, knowing it’s not a ground problem but also trying to be on the safe side, knowing her history with being right.

“How do you know where to start looking?” she asks. “Which dart would the monkey like first?”

“I’d like to see the camshaft-position-sensor (CMP) and the crankshaft-position-sensor (CKP) signals first,” I answer. “With this 3.0 double-overhead-cam (DOHC) engine being an interference engine, there stands a good possibility that the logic in the power control module (PCM) could be causing an rpm limit due to an ‘out-of-phase’ cam/crank-signal relationship.”

“What does … ?” Angel breaks in, but I proceed.

“The CMP and CKP signals tell the computer what position the engine is in so it can open the injectors and fire the plugs at the right time. If they get out of alignment with each other due to, say, a slipped timing belt – it could let the valves open at the wrong time and get hit by the pistons moving up, causing major damage to the engine.”

“So the guy could be right about the timing belt?” Angel asks.

I say, “It’s high on my list of suspects, but I’d still like to see it on the scope.”

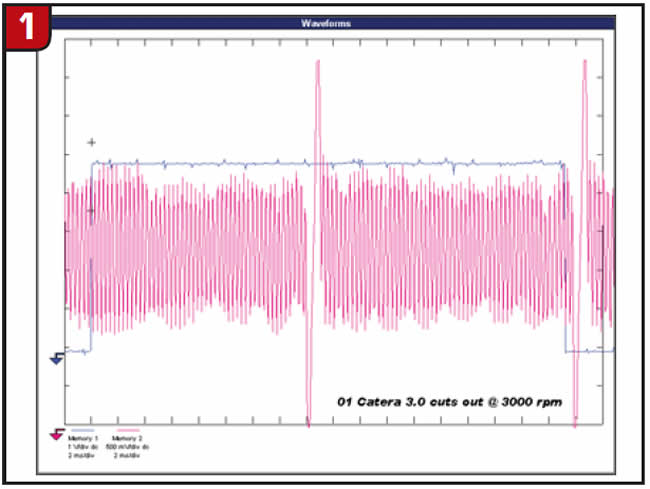

The PCM on this car is easily accessible and so are the connector terminals – more so than the timing marks on the four camshafts. I probed the cam- and crank-sensor signal circuits and set the scope to view their relationship (Figure 1).

I needed to get a better view and a better resolution of the CKP signal inside the CMP. To do this, I needed to get a tooth count from the edge of the CMP to the beginning of the CKP. I then wanted to compare them to a good source to determine whether the problem the car was experiencing might be related to a sync problem. I reset the scope to see the waveform in Figure 2, giving me a pretty good view of the tooth count I was after. I couldn’t find anything in either of my data sources showing the proper signal relationship. I decided to consult the iATN waveform library and found a few “known good” waveforms with which to compare. After careful consideration of the CKP peaks inside the CMP window (Figure 2), I decided the timing-belt theory was not going to be the issue.

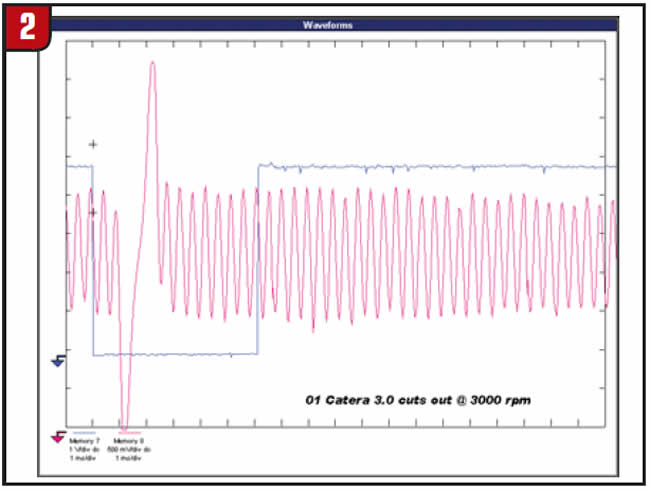

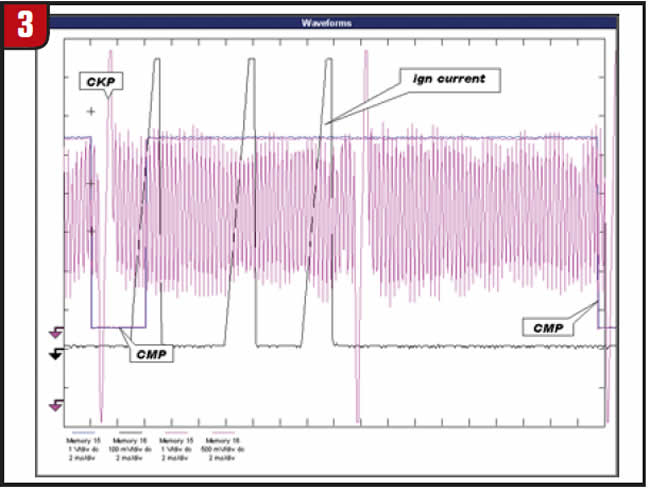

This result looked enough like the ones I referenced in the “known good” files that I decided to move on to another possibility. I found the wires to the coil feeds readily accessible and took a current probe and another scope on a test drive. I synced the second scope to the CMP signal and got the shot in Figure 3.

I caught this image during the “cut-out” event. As you can see, there are only three ignition-current events between CMP signals when there should be six. This seems to indicate that the problem is in the ignition system. This engine has cylinders 1, 3 and 5 on one bank with 2, 4 and 6 on the other. The firing order is 1, 2, 3, 4, 5, 6. The missing pulses represent firings from both sides of the engine. Now I’m suspecting it’s more of a PCM control problem. I found that if I let off the throttle enough to bring the rpms down under 2,900, I picked up the other three IGN signals as the engine smoothed out and ran perfectly.

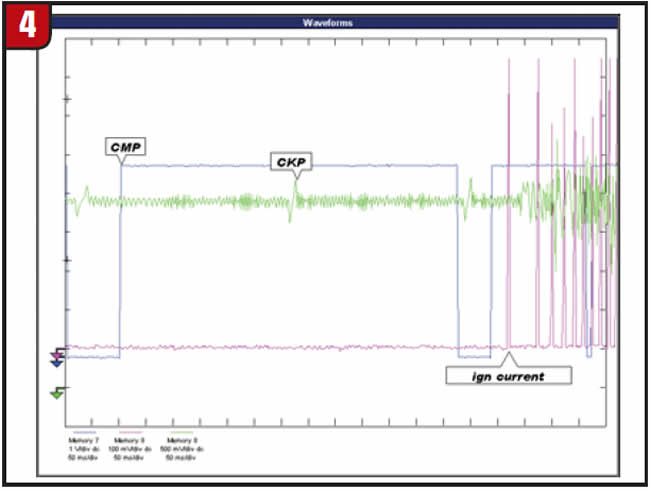

I took a shot of the ignition, CMP and CKP signals from a “cranking”-to-run situation with the scope set to capture 50 mS per division – and saved the shot in Figure 4.

I noticed a couple of interesting things here. I saw that the ignition current didn’t start to occur until after the second CMP signal. The other interesting thing was that the CKP signal was suspiciously weak looking. It was then I realized that the running CKP signals I had been collecting were all taken with the scope set to 500 mV per division. This is my usual setting for CKP cranking waveforms and requires changing to one or two volts per division to be able to frame the full signal on a running engine. These signals, although fairly normal looking, are actually quite low in amplitude. A weak crank signal now fits well as a suspect for everything I was seeing. It was also something I seldom encounter.

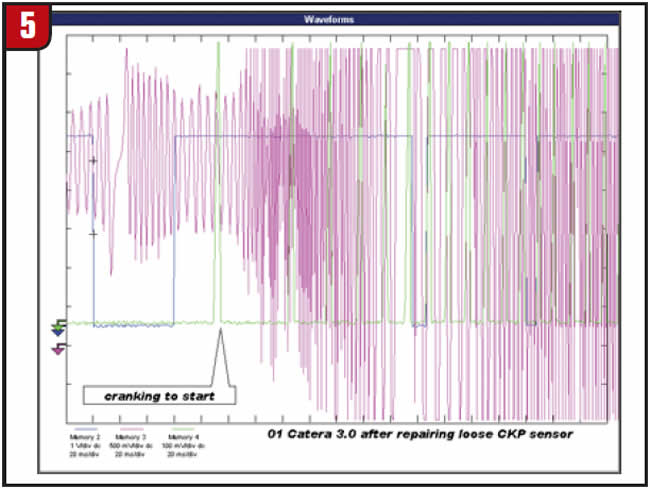

Crank sensors can cause a multitude of intermittent problems but are usually less consistent in their malfunction quirks. I raised the car on the lift, getting ready to check the sensor’s connection and resistance, when I noticed that the engine area around the crank sensor was saturated with oil. I could see, upon closer inspection, that the CKP-sensor O-ring was slightly visible. I reached up and pushed on the sensor and it moved nearly 1/8 inch, revealing that the bolt securing it to the block was finger tight. I snugged it up and lowered the car, anxious to take a new reading with the scope. I left the settings where they were and cranked up the engine again, and it started instantly. It now starts so fast that I had to change the time base to 20 mS per division to capture a decent image of the cranking to start a sequence of events. Notice in Figure 5 that the ignition current now begins right after the first CMP signal and the CKP signal then shoots up off the screen as the engine fires up.

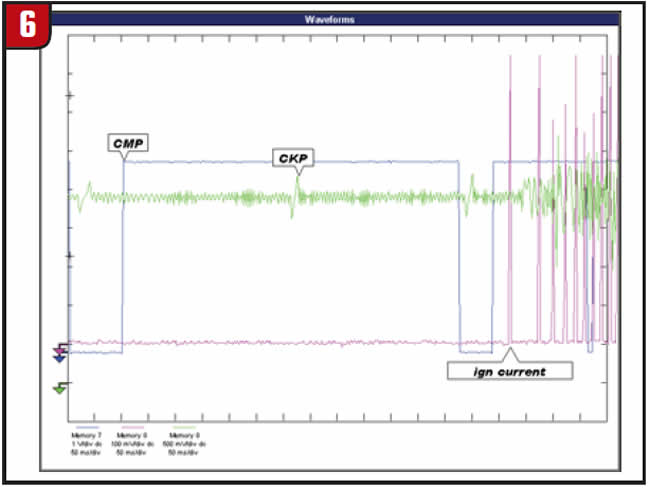

The rpm signal seen in Figure 6 now shows all six cylinder primary waves between the CMP signals, and the cut-out problem is gone.

I now get the task of relaying my findings to the guy who brought the car to us for the “pre-diagnosed” timing-belt replacement. Although the car may be in need of one, the timing belt is not going to solve the cutting-out problem. I know our diagnosis begs the question, “How do you know it’s not the problem?” So I arm Angel with the best waveform pictures and she gets to play “show and tell” as the guy not so reluctantly shells out the dough for the diagnosis.

Jeff Bach is the owner of CRT Auto Electronics, an ASA-member shop in Batavia, Ohio. For more information on this topic, contact Bach at 515-732-3965. His e-mail address is [email protected] and his Web site is www.currentprobe.com.

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.asashop.org or call 800-272-7467.