Midwest Transmission Supply (MTS)

Steve Farnsworth, founder and president of Omaha, Neb., based Midwest Transmission Supply (MTS), says that transmissions and the aftermarket is something he’s been around all his life. “My babysitters were truck mechanics,” he says. The family lived upstairs and owned a truck repair shop downstairs.

Farnsworth goes on to tell that at age 15 he landed a job at a local GM dealership where he would eventually learn the art of rebuilding both engines and transmissions. From the dealership he went on to be a technician in an AAMCO Transmission shop before he and another AAMCO technician opened their own shop, Clutch Masters. By the early 1990s, Farnsworth’s focus evolved to the parts supply side of the powertrain aftermarket. He was at first a salesperson for the Denver branch of Simi Valley, Calif., based Aceomatic. When the Denver branch closed in late 1993, Farnsworth purchased an Aceomatic franchise for Omaha and operated a warehouse under that name for the next three years. When the franchise contract lapsed, he decided to transition the distribution business to his own brand name, Midwest Transmission Supply.

While there have been and continue to be many family-owned specialty distributors of transmission and related parts, MTS differs by adding to the stock parts distribution business a varied line of performance transmission parts and units. As for the stock replacement lines, Farnsworth notes, “Our lines include parts for automatic transmission rebuilds, manual transmission rebuilds and transfer cases. We have both LuK and Valeo manual clutch kits.

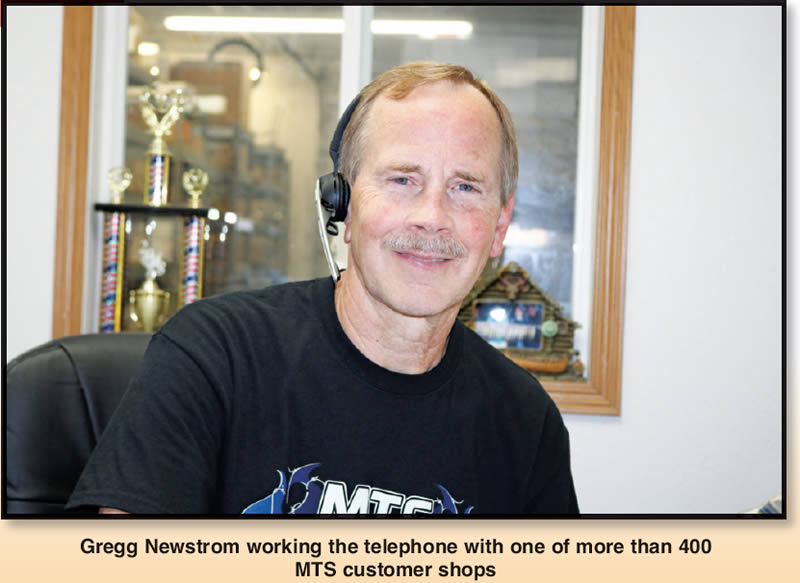

“We continue to operate as a small, family-owned business,” Steve says. Today, we have nine employees running this 15,000 square-foot facility and handling sales. “I’m personally averaging taking 50 to 70 calls a day, working with customers and taking orders. It’s a team effort of John, Greg and me on the phones. My son was involved in the sales efforts here until he recently relocated with his fiancée to the San Diego area.

“We add value to every customer relationship in some manner. And sometimes it’s different from one call to the next. We have the deep technical expertise to help guys with their builds. In this part of the country everybody wants to enhance their pickup or their street rod or something. We have all the parts that go into making any of the various popular units more robust.

“All of the people handling customer orders and that type of thing are car people with long experience at what they do. John Targy worked at his family’s auto-parts business. The business became more and more specialized in automatic-transmission parts over time. John brought that knowledge of the parts when he joined our company.

“Gregg Newstrom has specialized knowledge and experience from working as and for racing teams. Gregg was store manager of a speed shop during the 1980s and was parts manager at Certified Transmission before joining us here. And Gregg is a former drag racing champion in a 1963 Chevy II that ran the Super Street category at Scribner Raceway here in Nebraska.

“We prospect for new customers all the time. I do mailers to the states where we do business and I go out personally to make sales calls too. I think it’s important for me to introduce myself.

“In order to meet the people in the shops and talk to them about their business and offer our support, we participate in the ATSG and the ATRA seminars in the area and I bring my customers the Sonnax road show. We take that Roadshow to all the states where we’re doing business. We’ll take the Roadshow from shop to shop and I throw in some training from what we do. For example, this is what it takes to fix a 5R110 that you can stand behind with confidence.”

Again, Farnsworth emphasizes that the ability to offer technical support to builders is a successful way of building business and customer loyalty.

“Technical support is the thing that allows us to compete and prosper. Tech is really what I do! It’s something that a customer gets from MTS that isn’t available everywhere else. When a customer calls in and says, ‘hey Steve, I’m building a 6L80E; what do I put in it?’ So I’ll ask whatever questions need to be asked and then we’ll go through the parts needed for that job. We may start instead by diagnosing a problem that they have and coming up with the diagnosis based on the experience we have here. Because we offer the technical help, we gather the experience that comes from working through those problems. I’m dealing with a universe of about 400 shops where we’re talking about what’s wrong with this or that vehicle every day. I maintain a good relationship with the guys at Certified who have a lot of knowledge on building these units. The owner, Peter [Fink] has been my best friend for many years.

“Many of the shops we serve maintain stock inventory themselves as opposed to only buying when they have a car on the lift. This allows them to immediately start most jobs without waiting on a delivery, and many of these guys are re-selling parts in the local area as well. We buy direct on everything and we often supply some smaller suppliers too.”

Farnsworth says MTS serves those 400 customer shops across a seven-state area including North and South Dakota, Minnesota, Nebraska, Iowa, Kansas and Missouri. A couple of contract driver routes serve shops in Eastern and Central Nebraska and daily shipments are made to more distant customers.

“We go to market in a variety of other ways too.” Farnsworth continues. “The MTS Diesel line is custom kits, custom solenoids, billet parts and flex plates.

“We, for instance, make modified 5R110 solenoids that increase line pressure in those. All of the diesel parts that we sell to transmission shops are sold on that retail website as well. And we have a lot of shops that specialize exclusively in diesel trucks. Those guys often build their own transmission units out of parts that we supply.

“I’ve been around racing for as long as I’ve been around cars. I started racing motocross when I was nine years old and kept at that until age 34. I got into street racing here in Omaha for three years starting at age 16. I worked on drag race cars at the Scribner Drag Strip and on dirt track cars at Sunset Speedway. I was building motors and transmissions for both.

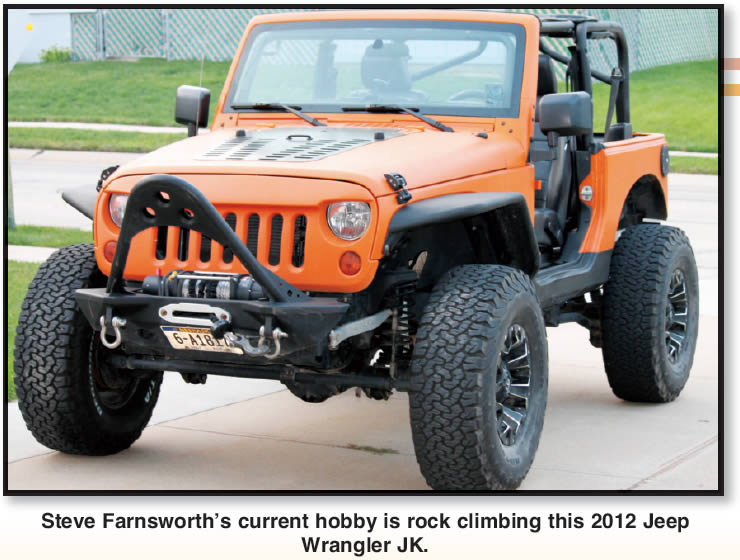

“My son and I got involved in sand drag racing; we ran an alcohol burning banshee in Little Sahara Oklahoma. And I’ve been rock crawling Jeeps my whole life. My latest build is a 2012 orange and black Linex Jeep JK long travel three-Link suspension front and rear with a six-inch extended wheel base, full roll cage. The body is wrapped in 3/16” steel.

“I used to race dirt late-models and we have assembled a line of parts for use in those. We’ll have the clutches and the other parts that those guys need to compete in late-model racing. At one time I was, in 2008, my best season, 16th overall in NASCAR points for dirt track crate motor late model racing. We stopped racing in that circuit several years ago. Now I’m racing SCCA Road Course and Pro Solo. I built a 425 hp Subaru WRX that has a coilover nitrogen suspension, 14-inch brake rotors, a full roll cage and a dry sump motor.

“The Camaro is my test vehicle for drag racing that we can put transmissions in and blow them up. We do the 6L80 800-horsepower Camaro testing. For the guys racing, we are primarily using the 4L60, 4L80 or more recently 6L80. That’s an LS Conversion car. We can put whatever transmission we want in there and program it and then see what happens.”

Farnsworth then explains, “MTS has a specialty in assembling performance units. For instance, I’ll put something together for a souped-up diesel truck. Certified will build the unit for that diesel. We’ll start adding and modifying the parts that go into that stock unit, testing each step of the way until we come up with the performance unit we want. I sell those solutions to my customers as parts and Pete sells the complete units that include those parts. That’s the way we’ve worked together over the years.

“For example, an order comes in for a performance unit that we’ve designed, we’ll give the special parts to the guys at Certified who actually build the unit to those specs and then we’ll get it delivered to the customer.

“We supply the specialty billet parts that he uses, mostly from our line of TCS parts. MTS is one of the biggest billet suppliers in the U.S. for the TCS parts line. And, we’re a Chrysler distributor and a Goerend Transmission distributor too. Performance stuff is where we really stand out. I build kits like a 68RFE custom kit to go with drum. I exchange information and ideas with a number of technical people throughout the industry.

“We do all the Goerend units in the country. They will have built the parts, a valve body and all the custom pieces that we will use. We order the parts a customer wants to include and then send them over to Certified for assembly of the unit. We deliver the unit to the customer, take care of the warranty and all of that. Everybody has a job to do to make just the right unit for the customer. Goerend runs half a dozen CNC machines making custom parts, we take care of orders and logistics and delivery and Certified handles the assembly and dyno testing of the unit. The customer gets the best of all our efforts and one incredible unit.”

We operate two websites that accept payment via PayPal: mts-diesel.com for the performance diesel parts and units, and serving the stock replacement parts we have midwesttransmissionsupply.com.