Up to Standards

- Subject: Design, operation and diagnosis

- Unit: BorgWarner 44-82 transfer case

- Vehicle Applications: Chevy Tahoe & Suburban, GMC Yukon & Yukon XL

- Essential Reading: Rebuilder, Diagnostician, R & R

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

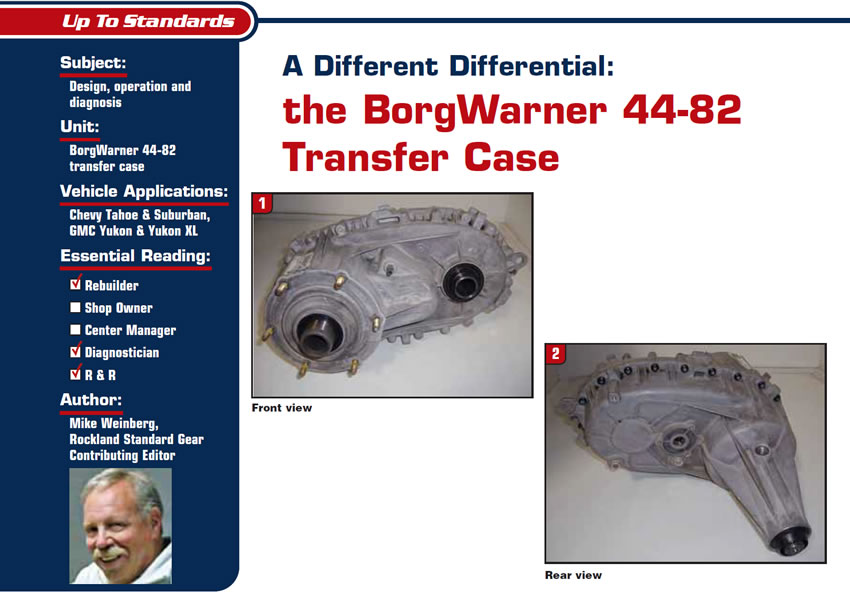

Beginning in the 2003 model year, General Motors introduced a new transfer case into its full-size-truck line. The Tahoe, Suburban, Yukon and Yukon XL all feature the BW 44-82 transfer case (figures 1, 2 and 3), which is a full-time unit.

The driver can select from three electronically shifted positions for the transfer case from a three-position switch mounted on the dash console. The gear-selection choices are 4High, Neutral and 4 Low lock, and the unit is always in 4WD unless shifted to a neutral position for towing. The Low-range function is strictly for off-road use and provides a 2.64-1 reduction in drive ratio for use in the boonies through a helical-gear planetary. The GM RPO code for this transfer case is NR4.

The 44-82 weighs 82.7 pounds dry and will hold 1.4 liters of Dexron III lubricant. The lube system, created by a gear-rotor-type oil pump that is driven off the main shaft, provides pressurized and filtered lube throughout the transfer case.

The case is made of high-pressure-cast magnesium, which demands some attention to detail in handling. I have had over the years a number of people who claimed they could weld magnesium. If you are going to try, remove the case from your shop and try it outdoors. Magnesium burns with an intensely bright white light, and if you use water in an attempt to put out the fire, it separates the oxygen from the hydrogen and feeds the combustion with pure oxygen while creating a hydrogen explosion.

The 44-82 has an open-center differential that splits the torque 40/60 front to rear. Understanding the operation of the full-time planetary differential in this unit is extremely important for proper assembly and diagnosis. The planetary differential (Figure 4) has two different sets of pinion gears and two different-sized sun gears. The planetary differential provides a constant 40/60 torque split (front to rear) full time, as the differential is an open type, which results in the prop shafts being driven for maximum traction at all times.

This “center differential” will operate exactly like a rear differential, providing two sets of side and spider gears. Understanding the problems that can occur with this system is critically important.

- Tire size and pressure must be equal in all four wheels. This does NOT mean simply that the sidewall labels all need to show the same size. The circumference around the center of the tread, measured by a tape measure or a stagger gauge, must be within 1/16 inch for all four tires.

- If the vehicle is on a lift with all four wheels off the ground, it is possible to turn the front driveshaft by hand.

- Do not run the vehicle on a hoist in the 4Hi Mode, because you can over-speed the differential pinion gears and cause the planetary differential to fail.

- Do not drive this vehicle with only one prop shaft, as you will lunch the planet differential.

- Do not tow with one set of wheels on the ground. Use a rollback only with all four wheels off the ground.

- Do not test this unit on a two-wheel dynamometer for emissions-inspection or other purposes. It may be driven on a four-wheel dyno.

This transfer case uses advanced electronic design to shift among different ranges and to enhance vehicle traction and handling for improved occupant safety. The unit is shifted through a three-position switch on the dash console. The transfer case has attached to it an electric shift motor and encoder to shift into different ranges and relay the motor rail position to the computer controls. Be aware that the motor is bi-directional through 12 volts, but the encoder setup uses a 5-volt reference signal for all other communication. Putting 12 volts to the encoder will cost you money.

To protect the driver from himself, this system monitors the speeds of all four wheels, steering angle and yaw rate and works with the antilock-brake, traction-control and stability-control systems. This is all put together under the Vehicle Stability Enhancement System (VSES), which can send torque to the axle that needs it and apply individual brakes as needed to regulate torque transfer to ensure the proper vehicle path through a turn.

The center differential that makes all this happen has two different-size sun gears and different-size pinion gears. These units generate a lot of tech-line calls, because once taken apart they cannot be reassembled unless you “time” the pinion gears. The pinion gears are marked with round dots that must be placed in the clock positions 12 noon, 3 p.m., 6 p.m. and 9 p.m. (Figure 5) before the sun gear can be installed into the carrier. Review the accompanying photos to get familiar with this setup.