Technically Speaking

- Subject: Problems causes by valve-sleeve and bore wear

- Unit: 722.6/NAG1

- Vehicle Applications: Mercedes, Dodge, Jeep

- Essential Reading: Rebuilder, Diagnostician

- Author: Wayne Colonna, ATSG, Transmission Digest Technical Editor

TCC judder

With the large number of 722.6 transmissions being used in both Mercedes vehicles and in Dodge and Jeep vehicles, where it is called the NAG 1, it is virtually certain that this transmission will end up in your shop for repairs. It may be that your shop refuses to work on Mercedes but Dodge and Jeep vehicles are all too welcome. And so it is in this way that if you have not worked on this transmission yet, you will. And it is not a bad unit to work on.

One problem this transmission is known for is valve-sleeve and bore wear, such as the overlap-valve sleeves and the pressure-regulator-valve bore. Yet another bore-wear problem that is often overlooked causes TCC judder, as described by the folks across the pond in Europe. It is not quite what we might call a chatter or shudder; it is more like a vibration. And depending on how good the main line-pressure system is, the problem could be described as a vibration followed by a very harsh engagement.

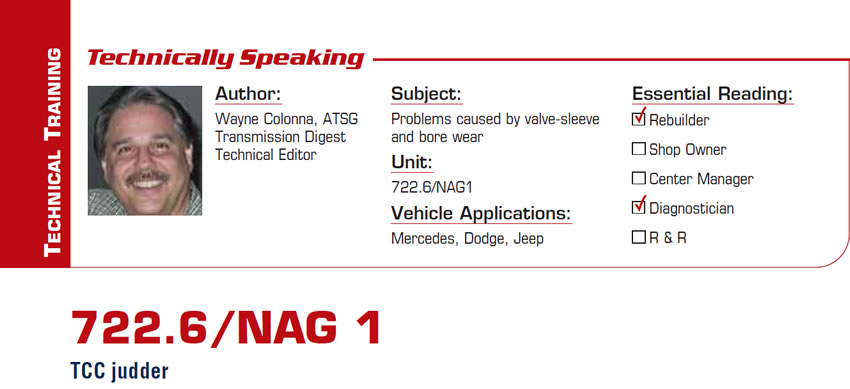

The valve we are talking about that is often overlooked is called the lubrication-pressure regulator valve (Figure 1).

Why would you look at the lubrication valve for a TCC issue – and especially so if the transmission doesn’t have a lubrication problem? But here is why: If you have never seen the inside of this converter you may not be aware that it actually has a clutch pack in it (Figure 2).

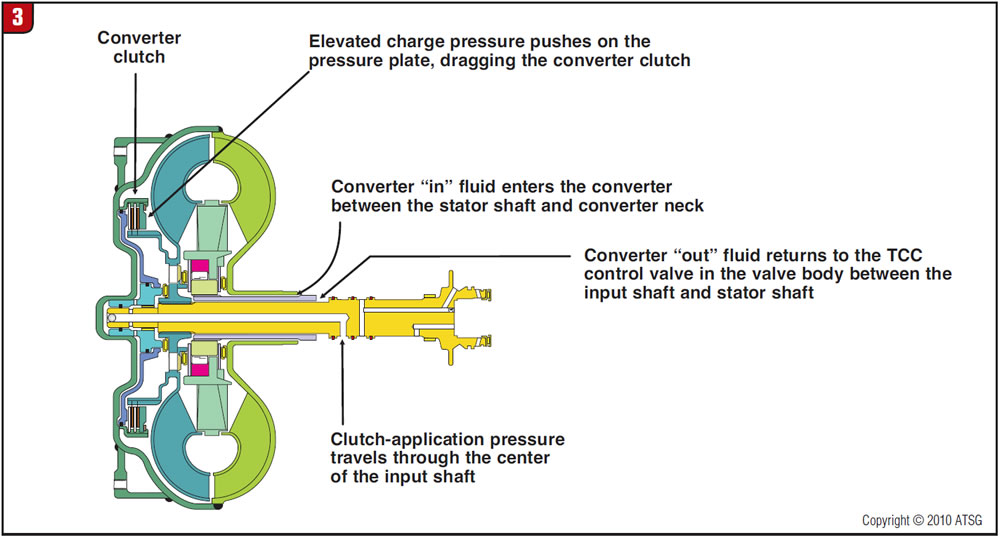

To turn the converter clutch on, pressure is supplied to the clutch drum through the center and out the tip of the input shaft. Take the pressure away and the clutch releases (Figure 3).

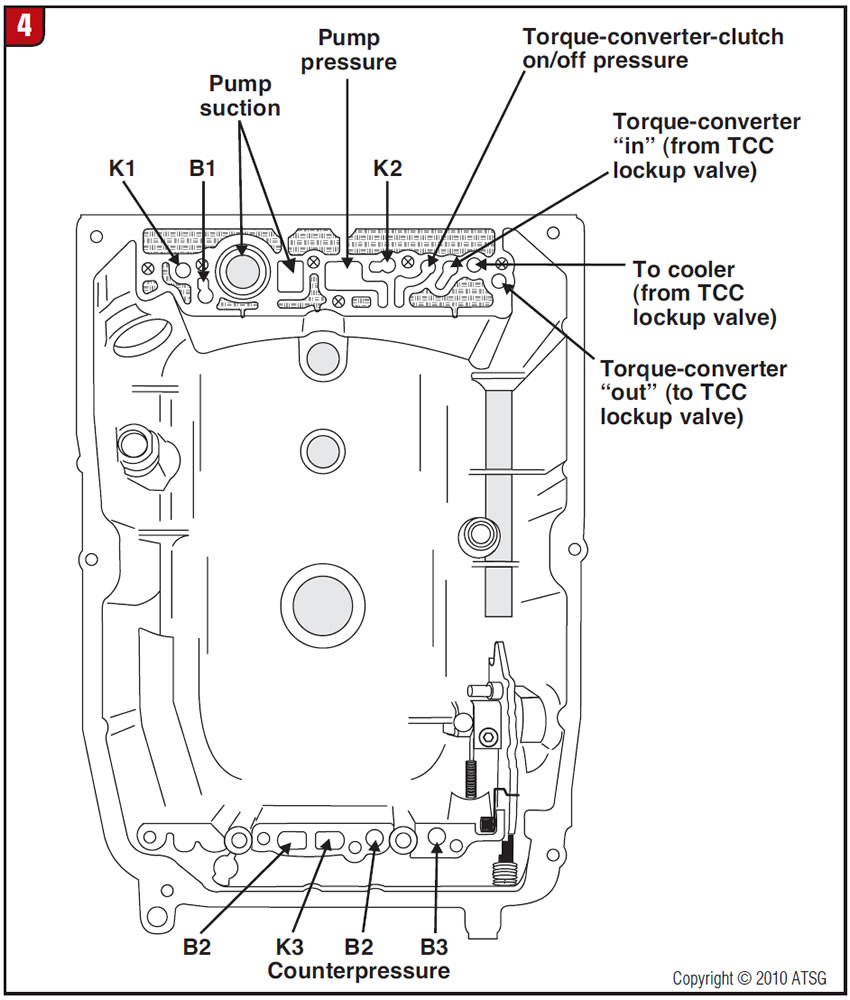

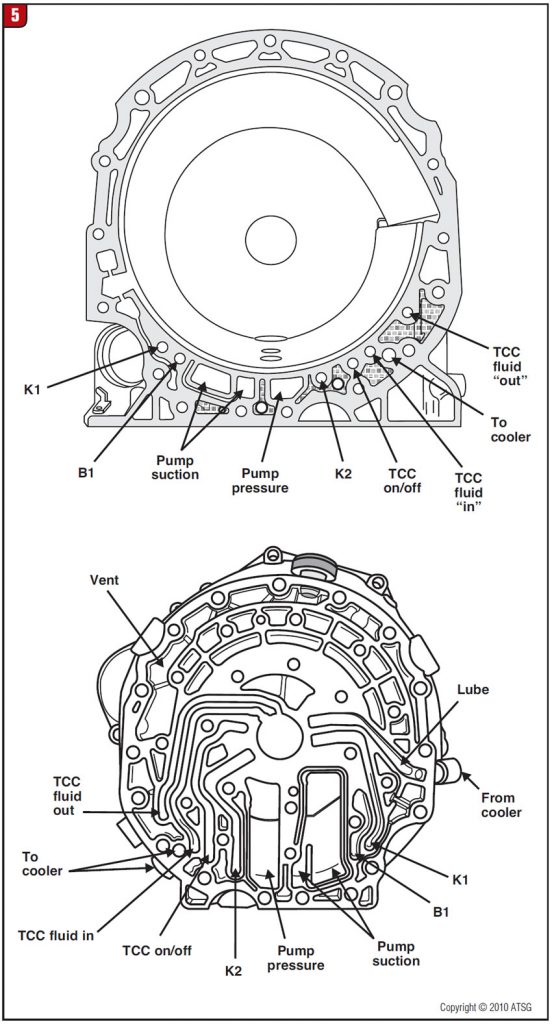

This means that this style of converter has three circuits: (a) the circuit we just mentioned that applies and releases the clutch pack in the converter, (b) a converter-charge or “in” pressure and (c) converter “out” to-cooler pressure. It is the lubrication-pressure regulator valve that regulates the converter “in” pressure, which becomes converter “out” pressure to the cooler (see identification of case and converter-housing passages in figures 4 and 5).

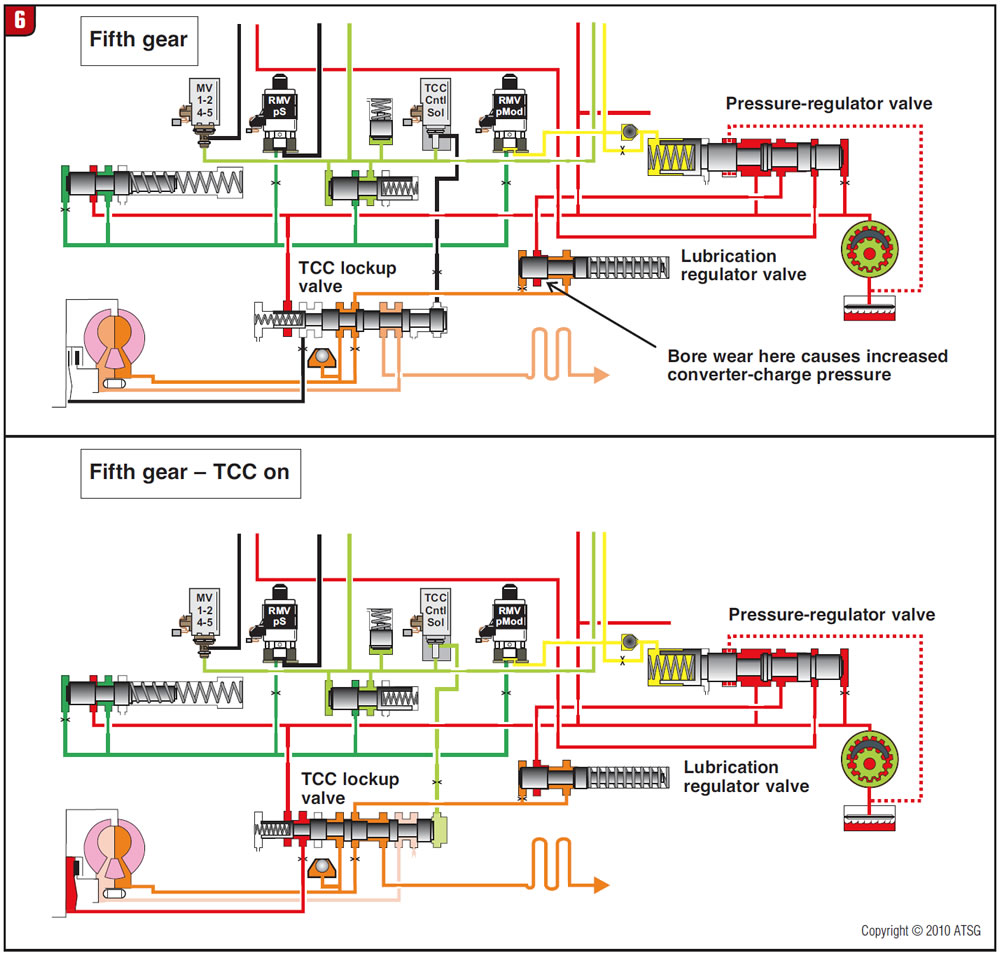

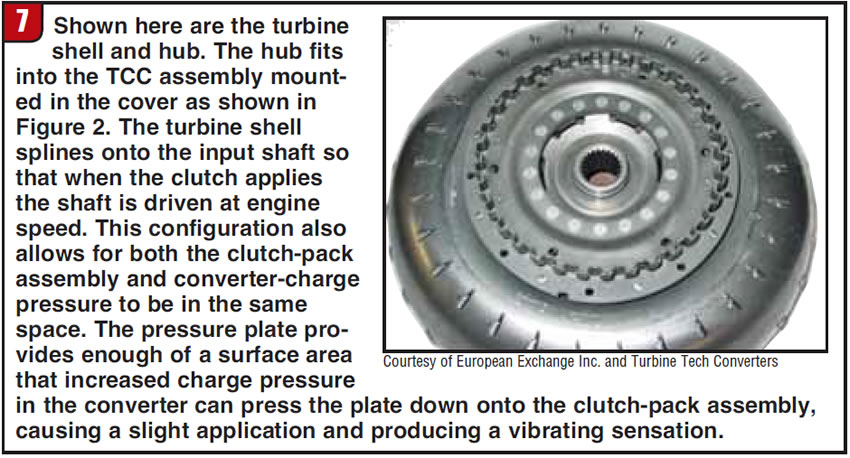

When the inboard land of this valve begins to wear the bore (Figure 1), unregulated line pressure is able to get into the converter-charge or “in” circuit, increasing the pressure inside the converter (Figure 6). The clutch-drum assembly inside the converter used for converter-clutch apply has a typical clutch pack, pressure plate and retaining snap ring (Figure 2).

The pressure-plate end of this clutch-drum assembly is open to the converter-charge or “in” circuit (Figure 7). With elevated pressure inside the converter due to a worn lubrication-valve bore, this pressure pushes on the pressure plate, partially applying the converter clutch and causing this vibration complaint (Figure 3). When the converter clutch is commanded on, the vibration stops, and depending on the integrity of the main line-pressure circuit this application can be very abrupt. This also explains why there is not a lubrication problem when this bore wears, as it is not starving the circuit but rather increasing the pressure in that circuit.

Another complaint this worn-bore condition causes is a stall into drive when cold. The reason is that the lockup solenoid is pulsed at about 40% in Park or Neutral and is pulsed off with a slight “on” time overlap when drive is selected. With increased pressure inside the converter pushing on the pressure-plate side of the clutch pack in combination with a slight amount of apply pressure in the piston side of the clutch pack, there is enough of an application of the clutch with cold oil to stall the engine. It is another bore that needs to be inspected, and word has it that a repair kit for this is on its way.

Many thanks to Nino Luongo from Beds Automatic Transmissions, England.