Technically Speaking

- Author: Mike Riley, Technical Editor

- Subject Matter: Lubrication

- Unit: 5R110W

- Issue: Cooler Line Inspection

We all know that certain transmission models exhibit problems based upon temperature levels. Most of the time, heat is the overriding factor, but in this installment of Technically Speaking, we’re going to look at models which are more susceptible to cold.

Later-model 5R110W transmissions could fit into this cold-temperature column; however, it would be prudent to inspect any 5R110W, regardless of the model year. When Ford launched the 5R110W in 2003, a unique cooler-line filtration system was developed and used for several years. Instead of a normal inline filter that merely splices into the pressure or return cooler line, the 5R110W used a bypass filtration design.

The bypass design looks like a plumber’s nightmare, but basically it channels the bulk of the cooler oil around the inline filter. A small amount of fluid actually is forced through the inline filter (which looks like a toilet-paper roll), providing extreme filtration. After a few thousand miles, all the fluid is cleaned at that level.

As time passed, someone at Ford decided that there had to be a better solution, so beginning in 2008, the external bypass system started to go away. It was replaced by a newly designed sump filter. This change, among others, has affected extreme-weather susceptibility of the 5R110W—especially in later models.

One issue that started to surface due to the design changes is failure of the low-diode One-Way Clutch (OWC), which now is a bigger deal because it’s made to the rear planetary.

To address the extreme cold-weather issues as well as accommodate the design changes, Ford released two different pumps for the 5R110W. Part number 9C3Z-7A103A, is to be used for models with the filter-bypass system and will retrofit to 2003. The other, part number 9C3Z-7A103B, is for applications that do not use the external-bypass system (Figure 1). There is a production part number, 9C3P-7A103AC, etched into the front face of the pump for I.D. purposes.

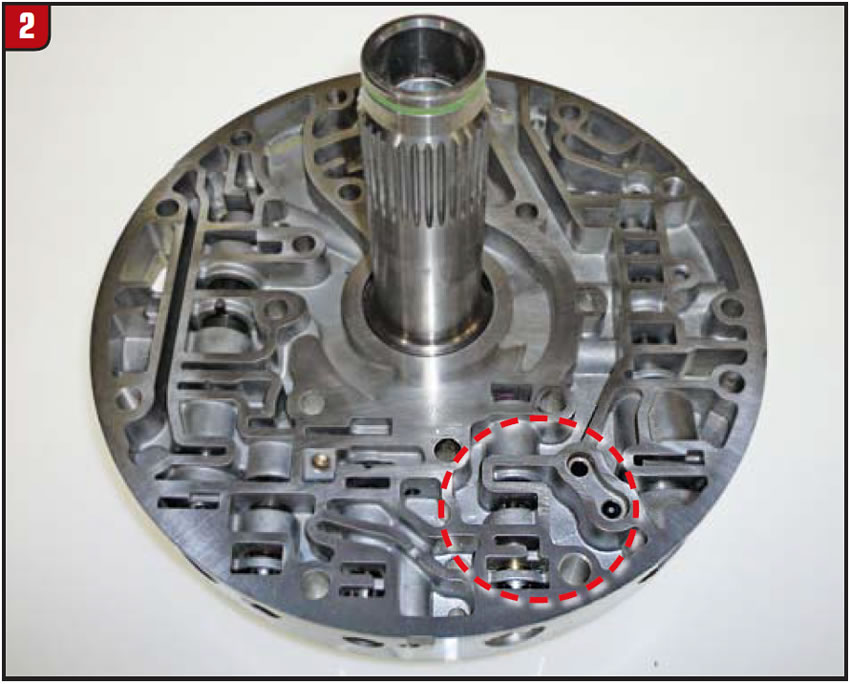

The pump-body and pump-cover castings basically are the same. Aside from the casting etched part numbers, only a difference in machining distinguishes the two designs. The pump bodies are the same between the two assemblies. It is the pump cover that’s different, and not by much (Figure 2).

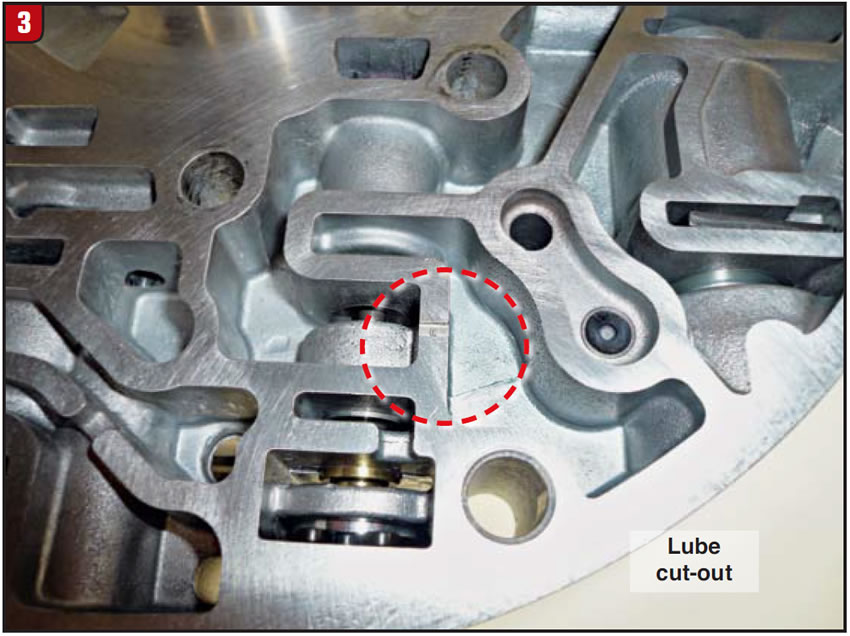

The pump cover that is for the non-bypass-design models has a notch cut into one worm track to allow oil flow to cross at all times (Figure 3). Apparently, the small notch is sufficient to maintain lube flow under all temperature conditions. The 9C3P-7A103AC (9C3Z-7A103B service #) is not to be used on filter-bypass models.

In the end, make sure that there is sufficient cooler flow under all conditions and on all 5R110W models.

Speaking of temperature-related issues, since winter is knocking on the door, another matter should be revisited: cooler-flow obstacles!

Jell-O®, an after-dinner snack, is great on the tastebuds, but gelatin in a transmission’s cooler lines is bad news. Any restriction to flow can allow transmission fluid to gel in a radiator tank or cooler lines, cutting off lubrication to the transmission. Although many transmission models have cooler-bypass capabilities, many do not.

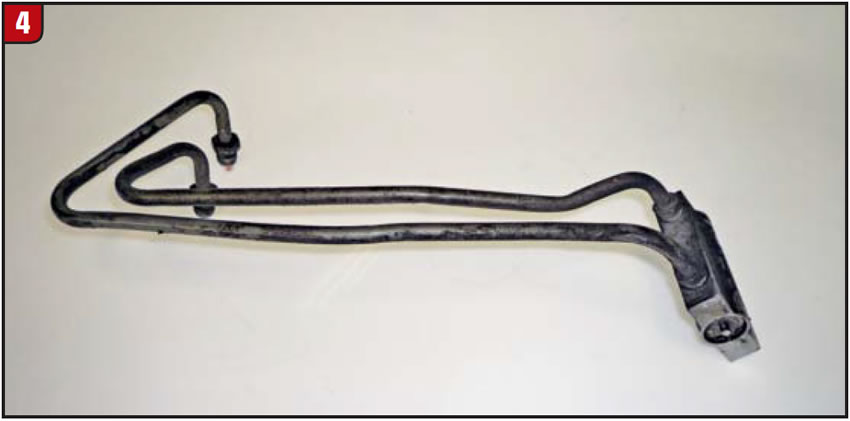

More vehicle models are equipped with a cooler-line thermal bypass than ever before (Figure 4).

If you are repairing a vehicle with one, it would be advisable to disassemble it to make sure that it is clean, free and functions correctly (Figure 5). If not, work done in October with the temperature at 50° could return on the hook in January, when the temperature is 20 below zero.

It’s all about good flow all the time, despite what the thermometer says.