Torque Converter Tech Tips

- Subject: Engine stalls on engagement into any drive range

- Units: 4R55E, 5R55E

- Vehicle Application: 1997 Ford Explorer 4.0-liter

- Essential Reading: Rebuilder, Diagnostician, R & R

- Author: Ed Lee

A local general-repair garage brought a 5R55E transmission and converter to a transmission shop for a rebuild. The transmission came out of a 1997 4.0-liter Ford Explorer with 216,456 miles on the odometer. The shop had the correct rebuilt transmission and converter in stock, so exchanging the change-over parts was all that was necessary to return the unit to the garage.

After what seemed to be a routine installation, the technician started to fill the transmission with ATF. Everything seemed to perform normally when the transmission was in the park or neutral range, but the engine would stall abruptly when the transmission was placed into any drive range. The transmission shop was called and the decision was made to have the vehicle towed back to the transmission shop for a closer look.

When the vehicle arrived, the tow-truck driver said he was able to drive the vehicle onto his rollback. Despite this information, all the normal external performance checks were completed before an attempt was made to drive the vehicle. All the tests, including a cooler-flow check, proved to be within the proper parameters. The only thing out of the ordinary was a P0743 code for an electrical-signature fault discovered during the scan check. The technician reasoned that the TCC was being applied because of a faulty or incorrect solenoid. When the vehicle was road-tested, performance was satisfactory. The only hint of a malfunction was a sensation of what was described as a slight dragging of the torque-converter clutch.

The decision was made to inspect and/or replace the TCC solenoid, so they dropped the transmission pan. When the pan came down, the technician found more ferrous-metal debris than would be expected after only a four-mile road test. It was obvious that there was more damage inside the unit and it needed to be pulled out.

When the converter was removed, the input shaft remained in the converter. This is not abnormal, but what was strange was that the shaft could not be easily removed from the converter afterward. When the input shaft was eventually removed, the damage to its end (Figure 1) began to tell the story, and the damage found to the inside of the converter cover (Figure 2) told even more of the story. It was now obvious that the input shaft was protruding too far from the front of the transmission, but why was this happening?

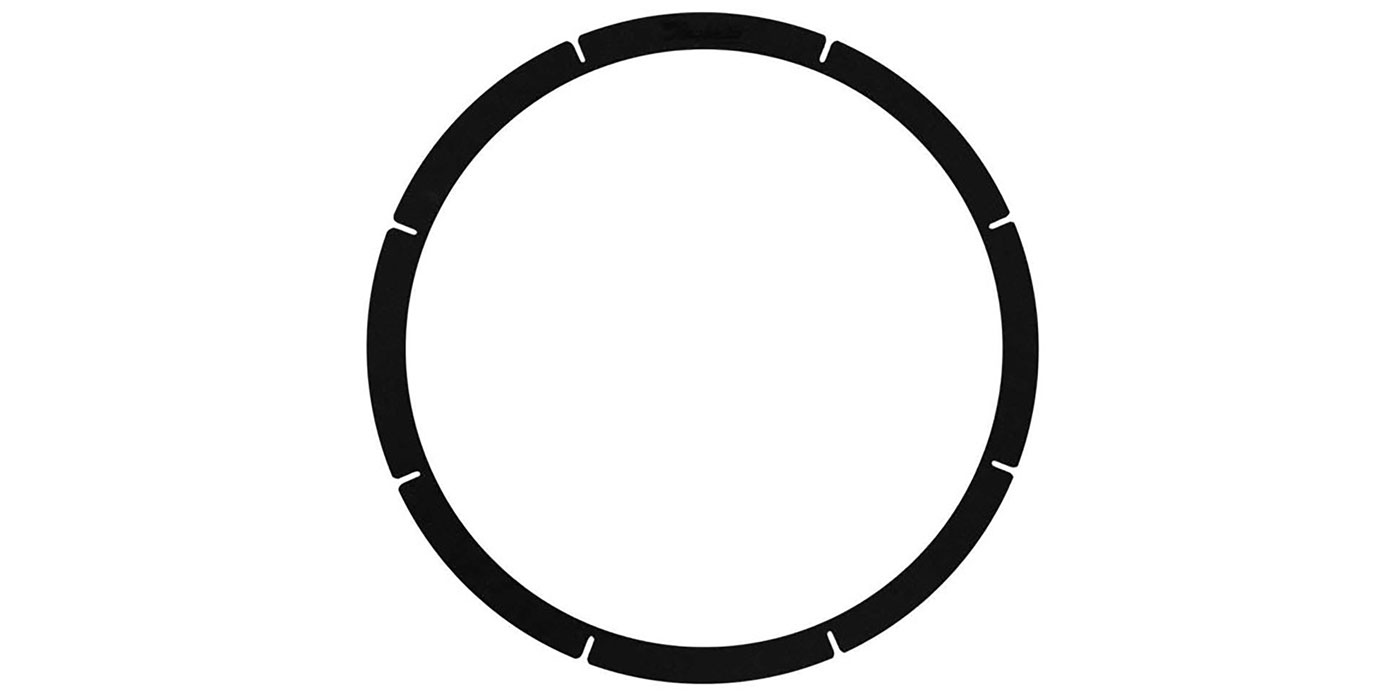

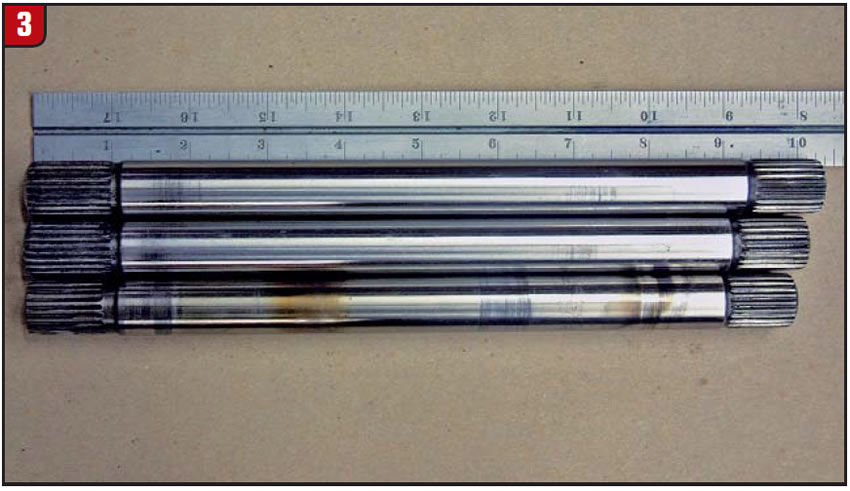

A 2002 ATSG tech bulletin (02-20) was found that warned of the existence of two input shafts of different lengths. If you start back at the A4LD shaft, there are actually three input shafts that have the same diameter and spline counts but are of different lengths (Figure 3).

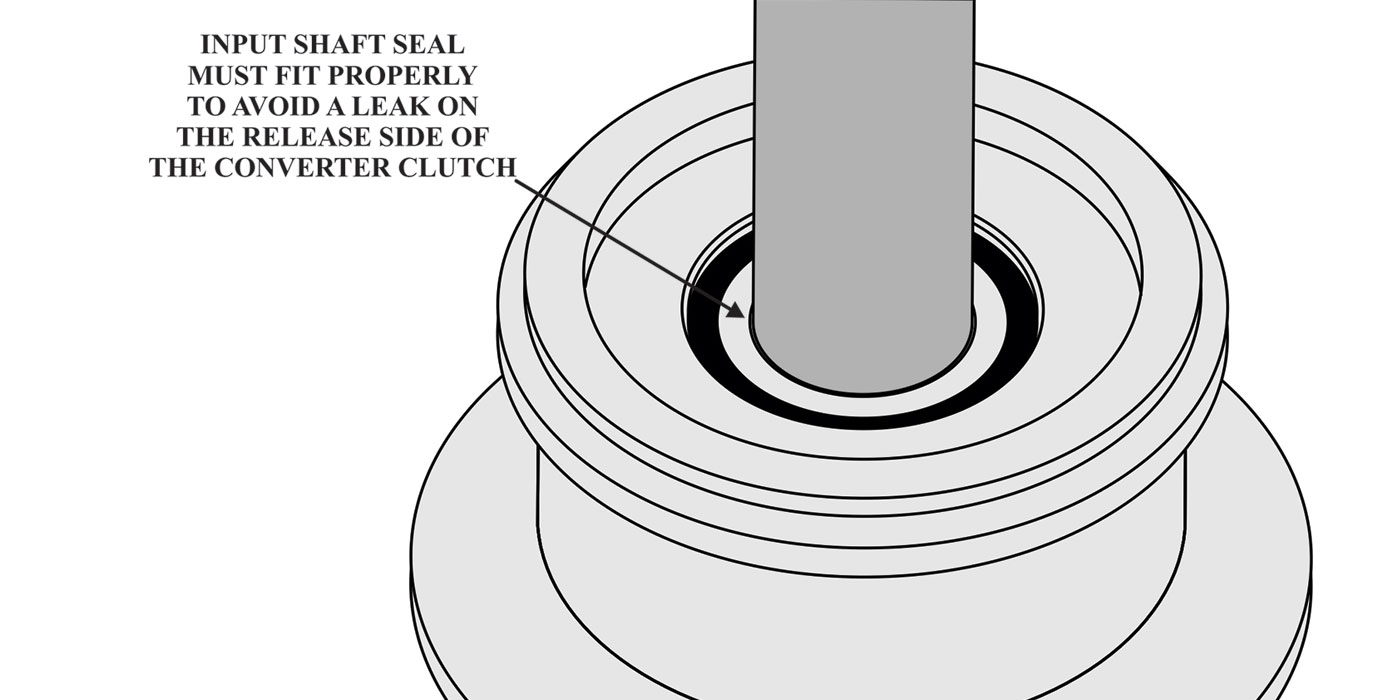

The A4LD shaft measures 97/8 inches long, the 4/5R55E shaft (XL2Z-7017-AA) measures 10 inches long and the 5R55 N/S/W shafts (XW4Z-7017-AA) measure 101/4 inches long. Although there may be some long-term damage from insufficient tooth contact when a shaft that is too short is used, the real danger comes from using a shaft that is too long. One inch is the proper distance that the input shaft should protrude from the stator support (Figure 4), but 11/4 inches is too long (Figure 5).

If the R&R technician had been paying close attention, he would have realized that something was wrong. With the converter traditionally being bottomed out against the transmission during installation, it is normal to have to pull the converter forward when attaching the flex-plate bolts. This “stab-depth” distance, normally 0.125-0.250 inch, would have been zero in this situation, because the shaft would have prevented the converter from moving as far in toward the unit as it normally would. If the R&R tech had noticed that the converter did not move forward, the shaft issue might have been caught before the damage was done.

Ed Lee is a Sonnax technical specialist who writes on issues of interest to torque-converter rebuilders. Sonnax supports the Torque Converter Rebuilders Association. Learn more about the group at www.tcraonline.com.

©Sonnax2010