TASC Force Tips

- Author: Ed Lee, Deltrans

Deja Vu All Over Again

If you were involved in the transmission industry when the E4OD transmissions began coming to local shops, you probably experienced the nightmare of cracked converter clutches. The primitive code-retrieval methods on the early transmissions were usually little help in finding the root cause of the problem. The aftermarket converter rebuilders recognized the cracks in the converter clutches early on. Some made vain attempts at welding the cracked converter clutches, while most others recommended a factory replacement converter.

Welding the cracked converter clutches proved to be a short-term fix at best, so most shops opted to buy the factory replacement. Fortunately for the industry, LuK began offering a superior replacement clutch. As soon as the aftermarket rebuilders began 100% replacement of the clutch, the problems coming to the local shops disappeared.

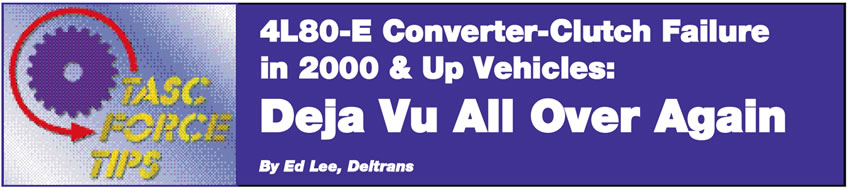

Today there is a new converter-clutch cracking problem. The 2000-and-up 4L80 E is having much the same problem as the early E4OD. See the 2003 ATSG white seminar book to identify the new unit. It appears that flexing is occurring just inboard of the circle of rivets, at a 90° crease formed during the stamping of the clutch (see Figure 1).

The cracks start out small and progress slowly. They seldom yield the devastating overheating results of their E4OD predecessors. Today’s friction material is so good that you will see hot spots on the front cover as the only evidence of a cracked clutch.

What the technicians will find is an 1870 code that is very difficult to diagnose. The code may not occur for 30-40 miles or even longer under light duty. The code will appear as soon as the clutch tries to apply in heavy-duty use such as towing or during operation in hilly terrain.

At this time, welding the clutch seems to be a viable option, although no long-term test results are available. The welded clutches have been in use for only six months or less (see Figure 2).

The opinion of most converter rebuilders is that the 2000-and-up clutches will have a significant failure rate. They recommend welding the clutch, even if it checks OK at the time of the rebuild.

Make sure that your rebuilder is aware of the problem and addresses it, until a better clutch is available.

The TASC Force (Technical Automotive Specialties Committee) is a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians.