Shift Pointers

- Subject: Redesigned pump assembly

- Unit: Chrysler 45/545RFE

- Vehicle Application: Dodge trucks

- Essential Reading: Rebuilder, Diagnostician

- Author: Pete Luban, ATSG, Transmission Digest Contributing Editor

I got a call last month from ATSG member Dan Tucker, who owns a shop in Pine Bluff, Ark. Dan, whose shop is in truck country, repairs many trucks of various kinds.

This article refers specifically to Dodge trucks equipped with 45/545RFE transmissions. Because Dan’s shop works on many of these units, which are known to have pump issues, he stocks new pumps on the shelf. When Dan called he explained to me that when he disassembled one of these brand-new pumps he noticed that the screws that hold the pump spacer plate to the pump body were missing. He wanted to know whether this could be some kind of assembly-line error and whether he should exchange the pumps for new ones.

Dan also told me that one of these new pumps was installed in a transmission that was going into a vehicle as we spoke. It turns out that the truck seemed to function properly.

At first I didn’t know what to say. I was not aware of any change that took place, so I said, “I don’t know but I will look into it.”

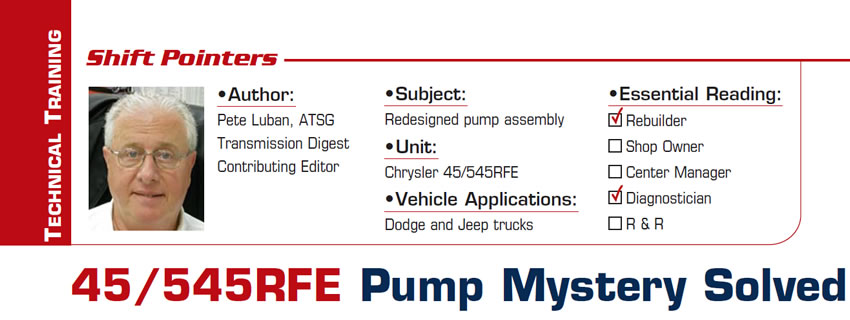

After acquiring the newly designed pump and comparing it with the previous design, I could see no difference (Figure 1). Both pumps had the same number of bolts holding them together, the spacer plate was the same thickness and the holes in the spacer plate were the same on both.

So now the question arises: How is it that when those screws were left loose or out in the previous-design pump, the truck would not move or you had to bring the engine speed way up to make it creep, yet the pump made without them seemed to work just fine?

It was time to ask for help, so I called Gregg Nader at Sonnax® to help me with pump-passage ID and to try to understand what could have changed. Greg mentioned that the screws are in a main-line-pressure passage. All of a sudden the light went on. As I was staring at the pump assemblies, I realized that was the key to unlocking this mystery.

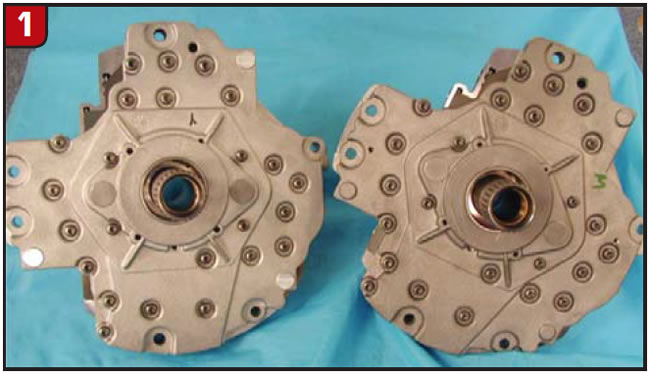

Figure 2 shows the previous-design pump body with the spacer plate screwed into place.

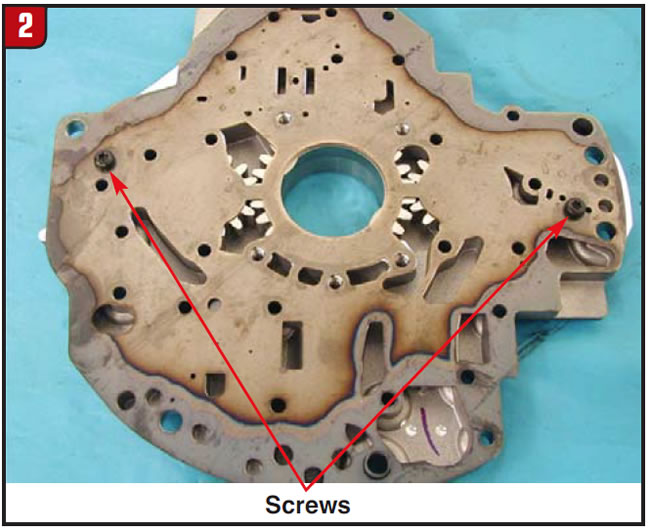

Figure 3 shows the newly designed pump body with the spacer plate in place but with no screws holding it down. The holes where the screws used to be are cast shut!

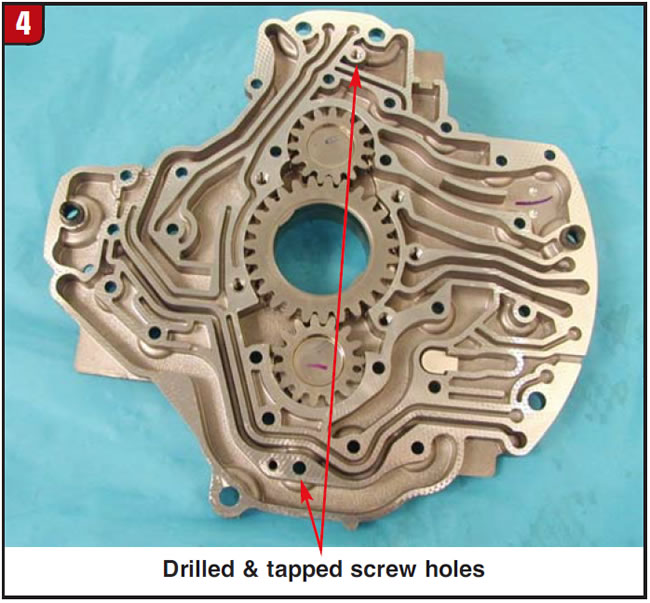

In Figure 4 with the spacer plate removed, you can easily see the screw holes in the previous-design pump.

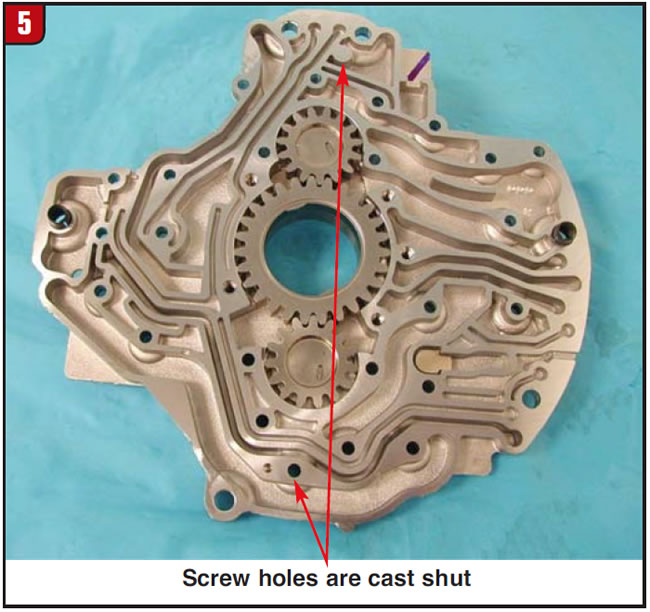

With the spacer plate removed from the newly designed pump in Figure 5, you can see the cast-shut screw-hole locations. This is why this pump assembly can work without the screws.

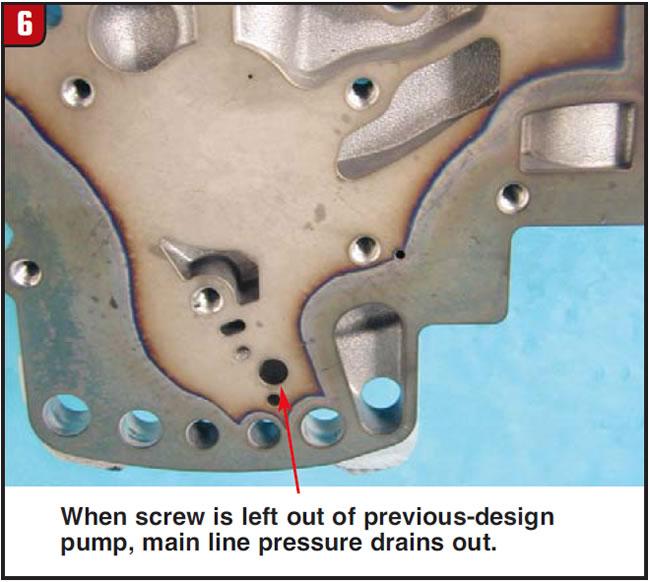

In Figure 6 the previous-design pump is shown with the screw left out.

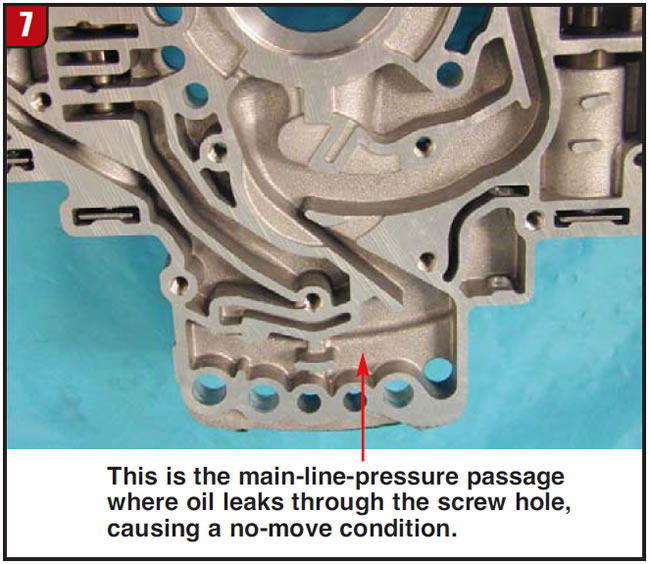

This empty hole is in the line-pressure passage in the pump cover (Figure 7).

When the screw is loose or left out, main line pressure leaks or dumps out through this hole, lowering line pressure enough to make this vehicle creep or not move.

Because those screw holes are cast shut in the newly designed pump, main line pressure cannot leak and, therefore, no screws are necessary. These screws may have been needed as part of the assembly-line process, which may have changed. The point is, these new pump assemblies work just fine without the screws – mystery solved.

The part number for the newly designed pump, which can back-service any 45/545RFE transmission, is 68009879AD.

Many thanks to Dan Tucker for the heads-up on this, and special thanks to Gregg Nader for his help in solving this mystery.